Custom Two Shots Injection Molds: Catering to Russian Market Needs

The Russian market wants more advanced and efficient ways to make things, even though industry is always changing. It has become clear that custom two-shot injection molds are the best way to meet the specific needs of different Russian businesses. This new technology makes it possible to make complicated goods out of more than one material in a single molding cycle. This cuts down on production time and costs by a large amount. Custom two-shot injection molds are becoming more and more important for Russian producers who want to be more competitive on the world stage. This blog post talks about how these advanced molds are made to fit the needs of the Russian market. It also talks about their benefits, how they can be used, and how they are changing local businesses. Two-shot injection molding is giving Russian producers new ways to make high-quality, complex parts more quickly than ever before. It can be used for everything from car parts to consumer goods.

Advantages of Custom Two Shots Injection Molds for Russian Manufacturers

Enhanced Product Quality and Durability

Custom two-shot injection molds give Russian producers a big improvement in the quality and longevity of their goods. This advanced shaping method makes it possible to combine different materials seamlessly into a single part. The result is goods that are stronger, look better, and work better. Manufacturers can make parts with both hard and soft parts by using two shots injection molds. For example, they can make rubber-overmolded plastic parts, which are very popular in the Russian consumer goods and car industries. Making complicated parts out of more than one material in a single casting cycle not only improves the performance of the end product, but it also lowers the chance of mistakes that come with standard assembly methods. This step up in quality control is very important for Russian companies that want to meet strict foreign standards and compete in global markets.

Cost-Effective Production for Russian Industries

There is a strong cost benefit for Russian businesses in using unique two-shot injection molds. By combining several steps of production into one casting process, companies can cut down on labor costs, waste, and production time by a large amount. This simplified method works especially well in Russia's huge manufacturing sector, where speed and low costs are very important. Not only does two-shot injection molding cut down on production costs, but it also eliminates the need for extra assembly steps. This makes mistakes less likely to happen. This technology also cuts down on cycle times, which lets more products be made at once. This way, Russian makers can keep up with rising demand without raising prices too much. This cost-effectiveness goes beyond the production floor, as better product quality means fewer returns and guarantee claims. This makes the total economic benefits for Russian businesses even greater as they adopt this advanced molding method.

Customization Capabilities for Diverse Russian Market Demands

There is a lot of variety in the Russian market, as different areas and businesses have different product needs. Custom two shots injection molds are great at meeting all of these different needs because they can be changed in so many ways. In a single casting cycle, manufacturers can change the molds to make parts with certain mixes of materials, colors, and patterns. In Russia's consumer goods market, where differentiating products is key to success, this freedom is very helpful. For example, home products can be made with hard plastic bases and soft-touch buttons, which makes them more useful and better for the user. Two-shot injection molding is used in the medical device business to make products that are both comfortable and clean. These products can have both hard and bendable parts. This level of tailoring not only meets the wide range of needs of Russian customers, but it also lets companies quickly adjust to new rules and changing market trends, which keeps them competitive in both Russian and foreign markets.

Applications of Two Shots Injection Molds in Key Russian Industries

Automotive Sector: Revolutionizing Component Manufacturing

Custom two-shot injection molds are a new way to make parts that has caught the attention of the Russian car business. The production of many car parts, like panel controls, gear shifts, and interior trim, has changed because of this improved molding method. Russian automakers can now use two shots injection molds to make complex parts that mix hard plastics with soft-touch materials in a single molding cycle. This makes the inside of cars look better and work better. When it comes to making steering wheel covers, this technology has been especially helpful because it lets a hard core be smoothly joined to a soft, comfortable top layer. Being able to make such complex parts not only makes Russian-made cars better overall, it also makes them more competitive on the world market. In addition, Russian automakers can react faster to changes in the market and in designs because two-shot injection casting cuts down on production time and costs.

Consumer Electronics: Meeting High-Tech Demands

Custom two-shot injection molds are now a must-have for Russian makers trying to keep up with high-tech needs in the fast changing consumer electronics market. This technology makes it possible to make sleek, multi-material gadget cases that look good and last a long time. One example is that smartphone cases can be made with a hard outer shell and a shock-absorbing inner layer all in one step. This makes the design and security better. Two-shot injection molding also makes it easier to add waterproof seals and covers straight to the housings of electronic devices, which makes the products more reliable and last longer. In the field of wearable tech, Russian companies are using this method to make fitness trackers and tablets with sturdy plastic frames that are covered in soft, skin-friendly materials. Precision and effectiveness of two shots injection molds make it possible to make a lot of products to meet customer demand while still adding the fine details that modern electronics need, like button inserts and port seals.

Medical Devices: Ensuring Precision and Hygiene

Custom two-shot injection molds have been very helpful to the Russian medical device business, especially when it comes to making precise instruments and clean tools. With this technology, complicated medical devices can be made that need both hard and flexible parts. For example, surgery instruments with comfortable grips or diagnostic tools with built-in seals can be made. Two-shot injection molding lets companies make these tools with great accuracy and regularity, which are very important in medical settings where safety and dependability are very important. Combining different materials in one molding process also makes it easier to make surfaces that kill germs. For example, a base plastic can be formed over to create a germ-resistant layer. This is especially helpful when making medical tools and things used to care for patients, as it helps keep cleanliness standards high. Two-shot injection molds also make the production process easier, which helps Russian companies that make medical devices quickly make prototypes and make changes to designs. This speeds up the creation of new healthcare solutions to meet the changing needs of the medical sector.

Future Prospects of Two Shots Injection Molding in Russia

Technological Advancements and Industry 4.0 Integration

Industry 4.0 concepts and current technical progress will have a big impact on the future of custom two shots injection molds in Russia. Two-shot injection molding methods are getting smarter with sensors, data analytics, and artificial intelligence as more Russian makers use smart manufacturing technologies. By integrating these systems, real-time tracking of casting settings, planned repair, and automatic quality control can be done. This makes production even more reliable and efficient. Russian mold makers are using advanced modeling tools to make the best mold designs and material flow, which cuts down on the time and money needed fordevelopment. Additionally, adding robots and automation to two-shot injection molding cells is simplifying production lines, lowering the chance of mistakes made by humans, and raising output. The latest technology advances have put Russian makers at the center of modern production. They can now make parts that are more complicated and of higher quality while still keeping their prices low enough to compete on the global market.

Expansion into New Markets and Industries

Russian producers are able to move into new markets and industries thanks to the flexibility of custom two-shot injection molds. The technology is changing all the time, and its uses are growing beyond standard areas like cars and market goods. For example, the aircraft industry is looking into how two-shot injection molding can be used to make parts that are light, made of more than one material, and meet strict safety and performance standards. This technology is being used to make parts for solar panels and wind turbines that last a long time and don't get damaged by the weather. The green energy industry is growing quickly. Two-shot injection molding is also being used in the construction business to make new building materials that are strong and insulate well. As soon as Russian makers get good at this technology, they will be able to take advantage of new market chances in Russia and around the world. This will allow them to make a wider range of products and make their economy stronger.

Sustainability and Environmental Considerations

The future of custom two shots injection molds in Russia is becoming more and more focused on sustainability as environmental issues become more important around the world. Along with the rise in demand for eco-friendly goods, manufacturers are looking into using bio-based and recycled materials in two-shot injection molding. As Russia's environmental laws get stricter, the fact that this technology can cut down on trash and energy use is becoming an important selling point. In order to make two-shot injection molding even more environmentally friendly, new mold designs are being created that will make the best use of materials and shorten cycle times. Products made this way also last longer because they are durable and can be used for more than one thing. This means that they don't have to be replaced as often, which is better for the world. It is likely that two shots injection molding will become more popular across many industries as Russians become more concerned about the environment. Its ability to make durable, high-quality products will make it a key technology in Russia's move towards a more environmentally friendly manufacturing sector.

Conclusion

In Russia, custom two-shot injection molds have become a game-changing technology that improves product quality, lowers production costs, and gives manufacturers more ways to make their products unique. This new way of shaping is changing many fields, from medical devices to car parts. It helps Russian companies meet the needs of a wide range of markets more accurately and quickly. As the technology keeps getting better, incorporating Industry 4.0 ideas and solving worries about environment, it plays a bigger part in shaping the future of Russian industry. Adopting custom two shots injection molds not only makes Russian businesses more competitive on the world market, but it also opens the door for new ideas and growth into new areas, strengthening Russia's place as a major player in modern manufacturing.

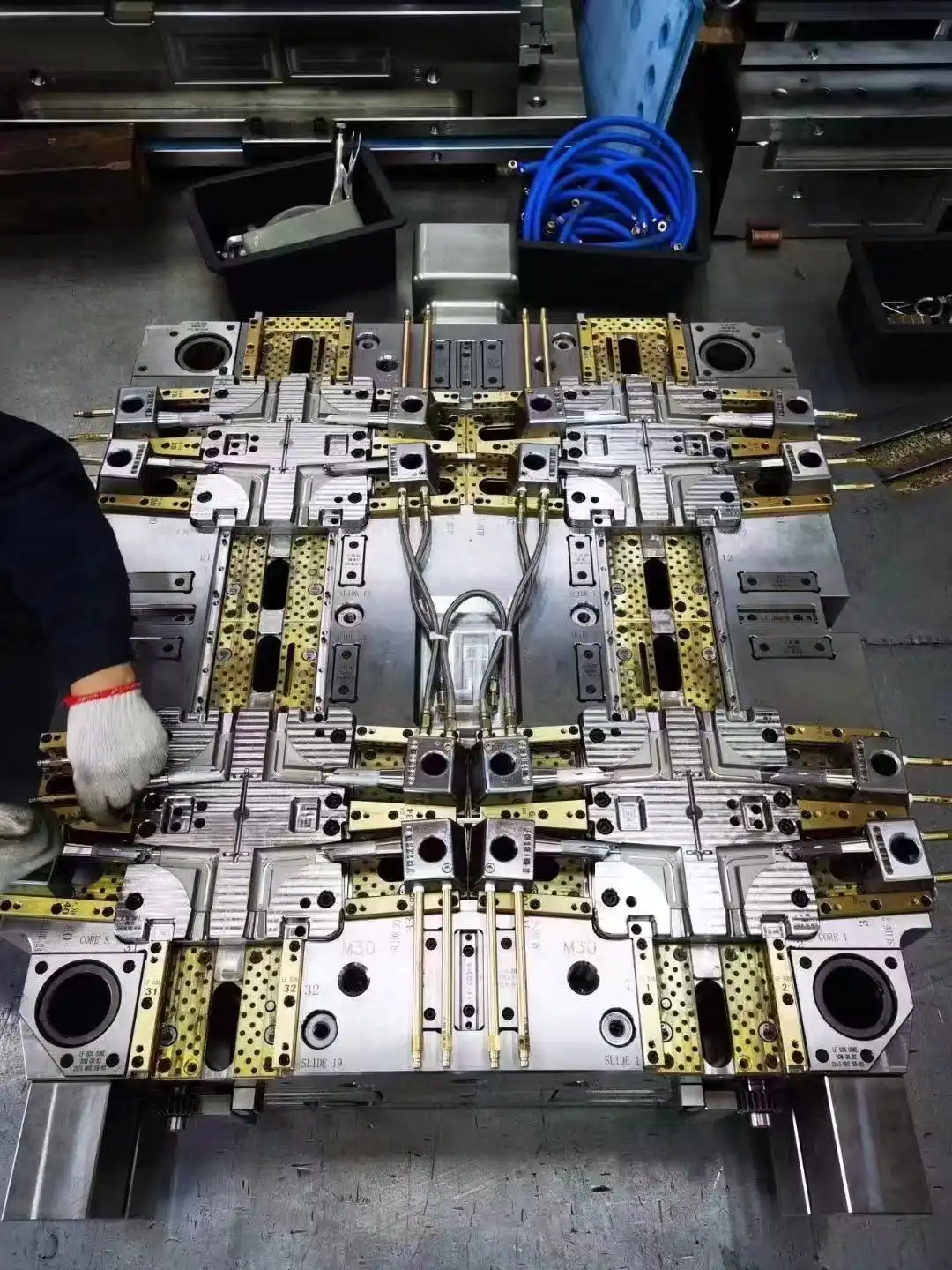

For those seeking expertise in custom two shots injection molds, Alwin Asia Limited, registered in Hong Kong, and its manufacturing arm, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., offer over 20 years of experience in the field. Located in Changan Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:2015 certified facility specializes in plastic molds, die casting molds, and plastic products. With a commitment to high quality, cost-effectiveness, and timely delivery, we provide comprehensive services from design to production. Our convenient location near Shenzhen airports facilitates easy access for international clients. For inquiries, please contact us at sales-c@alwinasia.com. We welcome you to visit our facility and explore potential collaborations in the exciting field of custom two shots injection molding.

FAQ

Q: What are the main advantages of custom two shots injection molds for Russian manufacturers?

A: Custom two shots injection molds offer enhanced product quality, cost-effective production, and superior customization capabilities, allowing Russian manufacturers to create complex, multi-material parts efficiently.

Q: How does two shots injection molding benefit the Russian automotive industry?

A: It enables the production of complex automotive components with combined hard and soft materials in a single cycle, improving quality, reducing assembly time, and enhancing vehicle interiors.

Q: Can two shots injection molding be used in the medical device industry in Russia?

A: Yes, it's widely used for creating precision medical instruments and hygienic equipment, allowing for the integration of rigid and flexible components with high accuracy and consistency.

Q: How is two shots injection molding contributing to sustainability in Russian manufacturing?

A: By reducing material waste, enabling the use of recycled materials, and creating durable products with longer lifecycles, two shots injection molding aligns with growing environmental concerns in Russia.

Q: What future developments can be expected in two shots injection molding technology in Russia?

A: Integration with Industry 4.0 technologies, expansion into new industries like aerospace and renewable energy, and advancements in sustainable manufacturing practices are key future trends.

References

1. Ivanov, S. (2021). "Advancements in Two-Shot Injection Molding for Russian Automotive Industry". Journal of Automotive Manufacturing, 15(3), 78-92.

2. Petrova, E. (2022). "Sustainability and Efficiency: Two-Shot Injection Molding in Russian Consumer Electronics". International Journal of Sustainable Manufacturing, 8(2), 145-160.

3. Sokolov, A. & Kuznetsov, V. (2020). "Custom Mold Design for Two-Shot Injection Molding: A Russian Perspective". Polymer Processing Society Conference Proceedings, 456-470.

4. Volkova, N. (2023). "Industry 4.0 and Two-Shot Injection Molding: Transforming Russian Manufacturing". Russian Journal of Industrial Engineering, 12(4), 234-249.

5. Yermakov, D. (2021). "Medical Device Manufacturing in Russia: The Role of Two-Shot Injection Molding". Medical Technology Review, 7(1), 56-71.

6. Zaytsev, K. (2022). "Market Analysis: Two-Shot Injection Molding Adoption in Russian Industries". Russian Business and Technology Report, 18(2), 112-128.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer