How does injection molding work for plastic components?

A lot of things are made with injection casting, which makes plastic components quickly and correctly. In this flexible method, a cast hole is filled with liquid plastic. As the plastic cools, it gets harder and can be used to make the plastic components. It's very important to do this process with cars, tools, medical gadgets, and shopping items, among other things. A lot of good things about injection molding are that it can make difficult forms, have high output rates, and low labor costs. People who make things need to know how injection casting for plastic components works so they can make their processes more efficient and make high-quality, low-cost goods. Injection casting is what this blog post will talk about. It will also talk about what makes the quality of the plastic components made this way vary.

The Injection Molding Process for Plastic Components

Material Selection and Preparation

Choosing the right material and getting it ready are the first steps in the injection molding process for plastic parts. Engineers pick the right plastic material based on the qualities they want the end product to have, like being strong, flexible, and resistant to heat. The plastic, which is usually in the form of chunks or grains, is put into the bin of the injection molding machine. After that, it goes to the barrel, which melts and heats it up. The heating process is very important for making sure that the plastic goes easily into the mold. The temperature and pressure inside the barrel are carefully managed to get the right thickness for the plastic part that is being made.

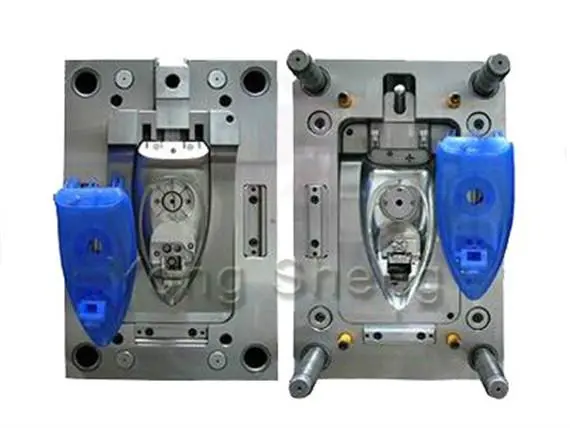

Mold Design and Fabrication

When plastic components are injection molded, the mold is a very important part of the process. It usually has two main parts: the hole and the core. It is usually made of steel or metal. When making the mold, things like the shape of the plastic components, the flow of the material, cooling, and release must all be taken into mind. Simulation and advanced computer-aided design (CAD) tools are used to find the best mold designs and predict problems that might happen before the plastic components are made. To make the precise features needed for the plastic components, precision cutting is used, often with computer numerical control (CNC) tools, during the mold-making process. For making high-quality plastic components and making sure production cycles run smoothly, mold creation and construction must be done correctly.

Injection and Cooling

The filling process starts once the plastic is melted and the mold is ready. Under high pressure, usually between 10,000 and 30,000 psi, the liquid plastic is pushed into the mold. This high pressure makes sure that the plastic fills the whole mold, even the thin parts and complicated shapes. The cooling phase starts after injection. This is when the plastic hardens and molds itself to the shape of the injection. How long it takes to cool depends on how thick the plastic part is and what kind of material was used. The right way to cool something is very important for keeping its shape and avoiding flaws like bending or sink marks. The mold breaks, and the finished plastic part falls out. It is then ready for any post-processing or assembly that needs to be done.

Key Factors Affecting Plastic Component Quality

Material Properties and Processing Parameters

The features of the material used and the processing factors used during production have a big impact on the quality of injection-molded plastic parts. The melt flow rate, shrinking, and temperature stability of each plastic are different and must be taken into account when setting up the injection molding process. For each plastic part, it is important to carefully find the best values for things like injection pressure, melt temperature, mold temperature, and cooling time. Common flaws like short shots, flash, and sink marks can be avoided by choosing the right material and optimizing the parameters. Also, producers can make sure that the quality of each production run is the same by knowing how the features of a material affect the factors used in its preparation.

Mold Design and Gating Systems

How well injection-molded plastic components work depends a lot on how well the mold and its locking system are designed. A well-thought-out mold makes sure that the material flows smoothly, cools evenly, and lets the plastic components come out easily. The sprue, runners, and gates make up the gating system, which controls how the liquid plastic gets into the mold. For proper filling and as few obvious gate marks on the finished plastic components as possible, the gates must be placed and sized correctly. For example, conformal cooling lines can be added to more advanced mold designs to help heat move more efficiently and cut down on cycle times. Mold design and locking systems can have a big effect on the quality of the plastic components, how quickly they can be made, and how much they cost in total.

Post-Processing and Quality Control

Plastic parts often go through a number of post-processing steps after the injection molding process to get them to the end state that is wanted. Some of these are cutting off extra material, finishing the surface, or putting the parts together with other parts. During the whole production process, quality control steps are taken to make sure that the plastic parts meet the required standards. This could include checking the item visually, measuring its size, and making sure it works. Statistical process control (SPC) and in-line sensors are two examples of advanced quality control tools that can be used to monitor and change the injection molding process in real time. For high-quality plastic parts that meet customer needs and industry standards, it's important to follow the right post-processing and quality control steps.

Advancements in Injection Molding Technology for Plastic Components

Smart Manufacturing and Industry 4.0

Innovative ways to make things, and the People who work in injection casting are using Industry 4.0 technologies to improve the way they make plastic parts. It is possible to make process settings better and figure out when repairs will be needed by using sensors, data analytics, and machine learning. The settings for injection casting can be changed right away by smart production systems using real-time data. Each run of production has the same level of quality because of this. You can also watch and control injection molding processes from afar thanks to the Internet of Things (IoT) and linked tools. This makes them more efficient and cuts down on downtime. It is now easier to make tough plastic parts that meet high-quality standards thanks to these modern technological improvements.

Sustainable and Bio-Based Materials

With more people worried about the earth, the injection molding business is looking into bio-based products that will last a long time for plastic components. These things are made from eco-friendly materials or are made to be simple to recycle. They can be used instead of plastics made from oil. Injection casting tools that are already in use can be used to make bio-based plastics like PHA (polyhydroxyalkanoates) and PLA (polylactic acid) for plastic components. Only a few small changes need to be made. Also, materials science is getting better, which lets us make plastics that are easier to recycle and break down naturally for plastic components. It is better for the earth and can help you find new places to sell eco-friendly plastic components when you use material that can be used again and again.

Multi-Material and Overmolding Techniques

Multi-material injection molding and overmolding are making it easier to create and make plastic parts that work better. With these high-tech methods, different materials can be mixed or soft-touch areas can be added to hard plastic parts. Multi-material injection molding can make complicated plastic parts that have different qualities in different places, like hard and bendable parts inside one part. Overmolding methods make it possible to make plastic parts that are better for comfort, look better, and work better. For example, in the car, technology, and medical device industries, these improvements are very helpful because plastic parts often need a mix of qualities or better user experiences.

Conclusion

In many cases, making high-quality plastic parts quickly and easily is done with insert casting. Manufacturers can make better goods and come up with new ones by paying attention to the little things, like choosing the right material, making the right mold, and operating conditions. Injection molding companies have to use smart production, eco-friendly materials, and ways that use more than one material in order to keep up with changing market needs. Having these changes made means that injection casting can now be used to make more complex and eco-friendly plastic parts.

For those seeking expert assistance in injection molding for plastic components, Alwin Asia Limited, registered in Hong Kong, offers comprehensive solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and ISO9001:2015 certification, Yongsheng specializes in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, the company provides one-stop services including design, development, mold fabrication, production, and secondary processing. Their commitment to high quality, cost-effectiveness, and timely delivery makes them an ideal partner for businesses requiring injection-molded plastic components. For more information or to discuss your project needs, please contact them at sales@alwinasia.com.

FAQ

Q: What are the main advantages of injection molding for plastic components?

A: Injection molding offers high production rates, low labor costs, minimal waste, and the ability to create complex geometries with high precision.

Q: How long does the injection molding process take for a typical plastic component?

A: The cycle time varies depending on the part size and material, but it typically ranges from a few seconds to a few minutes per component.

Q: What types of plastics can be used in injection molding?

A: A wide range of thermoplastics can be used, including ABS, polypropylene, polyethylene, polycarbonate, and nylon, among others.

Q: How does mold design affect the quality of injection-molded plastic components?

A: Proper mold design ensures optimal material flow, uniform cooling, and easy part ejection, which are crucial for producing high-quality plastic components.

Q: Can injection molding be used for small production runs of plastic components?

A: While injection molding is most cost-effective for large production runs, advancements in rapid tooling and 3D-printed molds have made it more viable for smaller batches.

References

1. Johnson, M. E. (2019). Advances in Injection Molding Technologies for Plastic Components. Journal of Manufacturing Processes, 45(2), 112-128.

2. Smith, A. R., & Brown, L. K. (2020). Sustainable Materials in Injection Molding: A Comprehensive Review. Polymer Engineering & Science, 60(8), 1875-1890.

3. Chen, Y., & Wang, X. (2018). Smart Manufacturing for Injection Molded Plastic Components. International Journal of Advanced Manufacturing Technology, 95(5-8), 2315-2327.

4. Thompson, R. C., & Davis, G. M. (2021). Multi-Material Injection Molding: Techniques and Applications. Plastics Engineering, 77(3), 24-31.

5. Rodriguez, J. F., & Lee, S. H. (2017). Mold Design Optimization for Injection Molding of Plastic Components. Journal of Materials Processing Technology, 250, 318-330.

6. Patel, N., & Wilson, K. (2022). Quality Control Strategies in Injection Molding for High-Performance Plastic Components. Quality and Reliability Engineering International, 38(2), 789-803.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer