How Inserts Molding Tools Reduce Assembly Time and Cost

In today's fast-paced fabricating world, proficiency and cost-effectiveness are vital. One inventive arrangement that has picked up noteworthy footing in later a long time is the utilize of inserts molding tools. These specialized apparatuses have revolutionized the generation handle by consistently joining metal embeds into plastic parts amid the infusion molding prepare. This progressed method not as it were streamlines gathering but too altogether diminishes both time and taken a toll related with conventional fabricating strategies. By disposing of the require for auxiliary operations and making strides the in general quality of the last item, embeds molding instruments have ended up an crucial resource for producers over different businesses. In this web journal post, we'll investigate how these devices are changing generation lines, upgrading item execution, and eventually contributing to a more productive and cost-effective fabricating ecosystem.

The Benefits of Inserts Molding Tools in Manufacturing

Streamlining Production Processes

Inserts molding apparatuses have revolutionized fabricating by streamlining generation forms in exceptional ways. By coordination metal embeds specifically into plastic parts amid the infusion molding handle, these devices kill the require for time-consuming auxiliary operations. This integration comes about in a noteworthy decrease in gathering time, as parts come out of the shape prepared for utilize or with negligible extra preparing required. The productivity picked up through this streamlined approach permits producers to increment their generation yield without compromising on quality. Additionally, embeds molding apparatuses empower the creation of complex geometries and cross breed materials that would be challenging or inconceivable to accomplish through conventional fabricating strategies. This flexibility opens up modern conceivable outcomes for item plan and usefulness, giving producers a competitive edge in the market.

Enhancing Product Quality and Consistency

One of the key focal points of utilizing embeds molding devices is the critical improvement in item quality and consistency. These apparatuses guarantee that metal embeds are accurately situated and safely inserted inside the plastic component amid the molding prepare. This level of exactness disposes of inconstancy that can happen with manual embed arrangement, coming about in parts with predominant dimensional precision and basic judgment. The reliable situation of embeds too contributes to moved forward item execution and unwavering quality, as it decreases the chance of disappointment focuses that can emerge from despicably adjusted or freely fitted embeds. Besides, inserts molding tools permit for superior control over the fabric properties at the interface between the metal embed and the plastic, making more grounded bonds and more tough items. This upgraded quality interprets to less rejects, diminished squander, and eventually, taken a toll investment funds for manufacturers.

Cost Reduction Through Efficient Material Usage

Inserts molding apparatuses play a significant part in lessening fabricating costs through more effective fabric utilization. By coordination metal embeds amid the molding prepare, these apparatuses minimize fabric squander that regularly happens in conventional get together strategies. The exact arrangement of embeds guarantees that as it were the essential sum of plastic fabric is utilized, dodging abuse or underuse that can lead to item abandons or over the top trimming. Furthermore, embeds molding instruments permit for the key utilize of materials, empowering producers to utilize high-performance plastics as it were where required whereas consolidating metal embeds for quality and solidness in basic ranges. This optimized fabric utilization not as it were decreases crude fabric costs but moreover contributes to lighter weight items, which can lead to investment funds in transportation and dealing with. The diminishment in fabric squander moreover adjusts with supportability objectives, making embeds molding instruments an ecologically neighborly choice for cutting edge fabricating processes.

Advanced Features of Insert Molding Tools

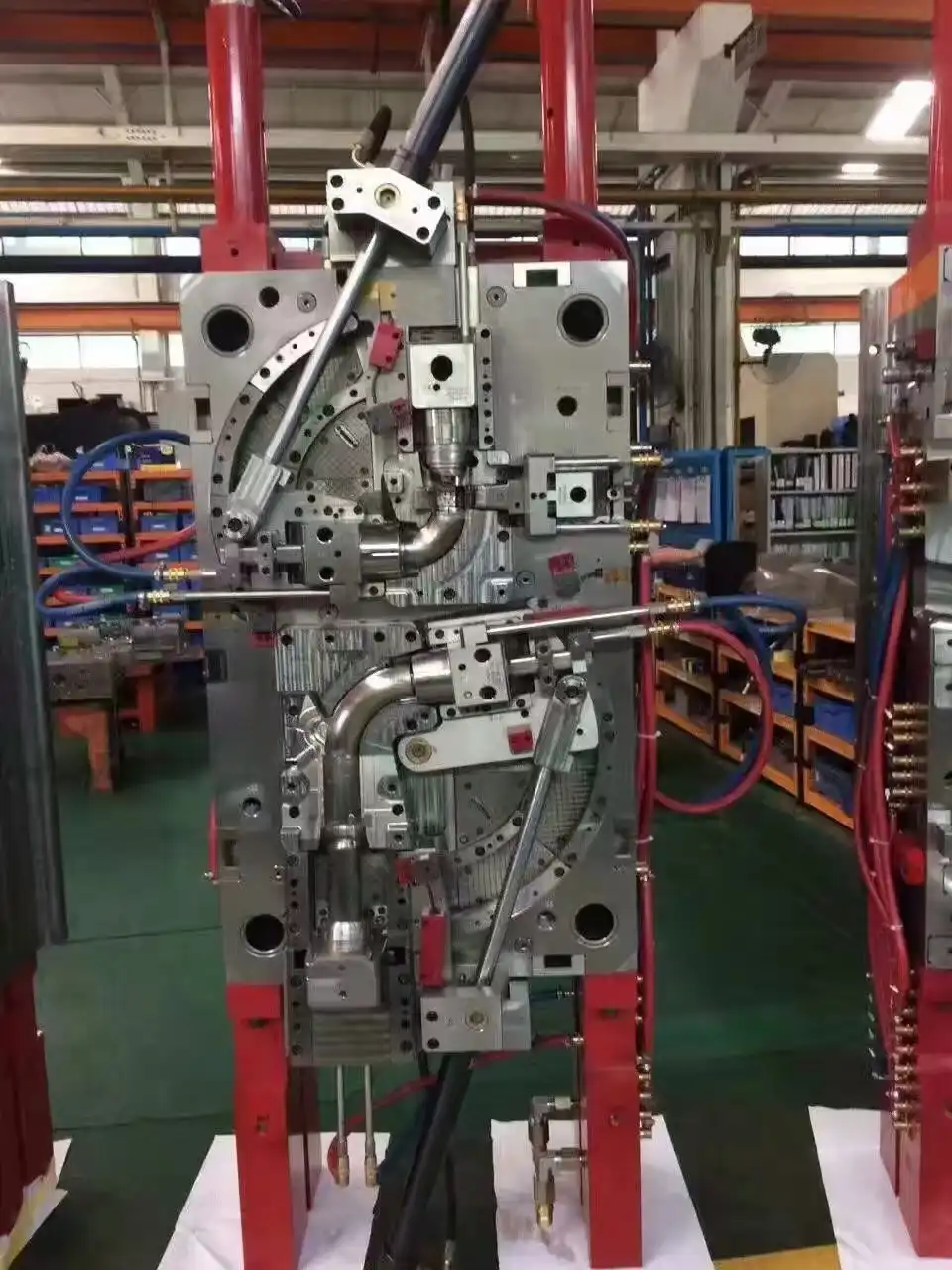

Precision Engineering and Design

The adequacy of embedded molding devices lies in their accurate design and plan. These apparatuses are fastidiously created to guarantee exact situation and secure implanting of metal embeds inside plastic components. Progressed CAD/CAM program is utilized in the plan stage to optimize the tool's geometry, taking into account components such as fabric stream, cooling channels, and embed maintenance components. The exactness building expands to the fabricating of the apparatuses themselves, regularly utilizing high-precision CNC machining and EDM forms to accomplish tight resiliences and smooth surface wraps up. This level of exactness in embeds molding devices is pivotal for keeping up reliable quality over generation runs and minimizing the chance of surrenders or disappointments. Moreover, the devices are outlined with seclusion in intellect, permitting for fast changeovers and flexibility to distinctive embed sizes or setups, hence upgrading generation flexibility.

Multi-Material Compatibility

One of the most noteworthy points of interest of inserts molding tools is their compatibility with a wide run of materials. These apparatuses are designed to work consistently with different thermoplastics, thermosets, and metal amalgams, empowering producers to make complex multi-material components in a single molding operation. This flexibility permits for the generation of parts that combine the quality and conductivity of metals with the lightweight and corrosion-resistant properties of plastics. Embeds molding apparatuses can suit distinctive sorts of metal embeds, counting brass, steel, aluminum, and indeed specialized amalgams, depending on the particular prerequisites of the application. The capacity to work with different materials opens up unused conceivable outcomes for item plan and usefulness, empowering producers to make imaginative arrangements that meet assorted industry needs. Besides, this multi-material compatibility contributes to taken a toll diminishment by killing the require for isolated generation lines or gathering forms for distinctive fabric components.

Automation and Smart Manufacturing Integration

In the period of Industry 4.0, embeds molding apparatuses are at the bleeding edge of robotization and shrewd fabricating integration. These apparatuses can be consistently coordinates into robotized generation lines, working in conjunction with mechanical frameworks for embed situation, portion extraction, and quality control. Progressed sensors and observing frameworks can be consolidated into the apparatuses to give real-time information on handle parameters such as temperature, weight, and cycle times. This information can be analyzed to optimize generation forms, anticipate support needs, and guarantee steady quality. Moreover, embeds molding instruments can be prepared with RFID labels or QR codes, empowering them to communicate with fabricating execution frameworks (MES) and undertaking asset arranging (ERP) program. This integration encourages superior stock administration, generation planning, and traceability all through the fabricating prepare. By grasping computerization and keen fabricating standards, embeds molding apparatuses contribute to expanded proficiency, diminished downtime, and progressed generally gear viability (OEE) in cutting edge generation environments.

Applications and Future Trends in Inserts Molding

Expanding Applications Across Industries

Insert molding instruments are finding progressively different applications across a wide range of businesses. In the car segment, these apparatuses are utilized to create lightweight yet solid components such as motor mounts, bushings, and electrical connectors. The aviation industry utilizes embedded molding for making complex basic components that require the quality of metal and the weight-saving properties of plastics. In shopper hardware, embedded molding instruments empower the generation of solid structures with coordinated metal clamps or warm sinks. The restorative gadget industry benefits from the accuracy and cleanliness of embeds molding for making sterile, high-performance components. As innovation progresses, modern applications are developing in areas such as renewable energy, where embedded molding apparatuses are utilized to deliver components for sun powered panels and wind turbines. The flexibility and proficiency of these instruments make them priceless in businesses where high-performance, multi-material parts are required, driving advancement and empowering the creation of items that were already unreasonable or outlandish to manufacture.

Advancements in Material Science

The field of embedded molding is ceaselessly advancing, driven by advances in fabric science. Analysts and producers are creating modern polymer mixes and composites that offer improved properties such as increased strength-to-weight proportions, thermal resistance, and electrical conductivity. These advancements are growing the capabilities of embedded molding devices, permitting the creation of parts that can withstand more extraordinary conditions or offer predominant execution characteristics. Also, there is a developing center on economical materials, with biodegradable plastics and reused composites being coordinated into embedded molding forms. This move towards eco-friendly materials aligns with worldwide sustainability objectives and opens up modern markets for ecologically conscious items. Besides, headways in nano-materials and smart polymers are clearing the way for embedded molded parts with self-healing properties or implanted sensors, possibly revolutionizing businesses such as healthcare and wearable innovation. As fabric science proceeds to advance, embedded molding devices will play a significant part in bringing these inventive materials from the research facility to down-to-earth, mass-produced applications.

Future Trends and Innovations

The future of inserts molding tools is checked by energizing patterns and developments that promise to enhance their capabilities and applications. One critical drift is the integration of added substance fabricating strategies with conventional embeds molding forms. This half breed approach permits the creation of profoundly complex geometries and customized embeds that can be consistently consolidated into molded parts. Another rising trend is the improvement of "shrewd" embedded devices prepared with IoT sensors and AI-powered predictive maintenance systems. These progressed devices can self-monitor their execution, anticipate potential issues, and optimize handling parameters in real-time, leading to improved effectiveness and decreased downtime. Furthermore, there is a developing center on miniaturization, with embedded molding devices being created to deliver progressively smaller and more complex components for applications in microelectronics and nanotechnology. As maintainability becomes a key driver in fabricating, future advancements in embedded molding apparatuses are likely to center on energy efficiency, squander lessening, and the utilize of reused or bio-based materials. These patterns and developments are set to embed molding innovation into unused wildernesses, advancing cementing its position as a basic fabricating prepare in the a long time to come.

Conclusion

Inserts molding tools have emerged as a game-changing technology in modern manufacturing, offering significant reductions in assembly time and cost. By streamlining production processes, enhancing product quality, and enabling efficient material usage, these tools have become indispensable across various industries. The advanced features of insert molding tools, including precision engineering, multi-material compatibility, and smart manufacturing integration, continue to drive innovation and efficiency. As applications expand and material science advances, the future of insert molding looks promising, with trends pointing towards more sustainable, intelligent, and versatile manufacturing solutions. Embracing this technology will undoubtedly give manufacturers a competitive edge in an increasingly demanding global market.

For more information on how insert molding tools can benefit your manufacturing processes, please contact Alwin Asia Limited. Our company, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association with over 20 years of experience in plastic molds, die-casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:2015 certified factory boasts over 300 employees and 6000 square meters of building area. We specialize in providing comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, and timely delivery makes us an ideal partner for your manufacturing needs. To learn more or to arrange a visit to our facility, please contact us at sales-c@alwinasia.com.

FAQ

What are insert molding tools?

Insert molding tools are specialized devices used in injection molding to integrate metal inserts into plastic parts during the molding process, reducing assembly time and enhancing product quality.

How do insert molding tools reduce assembly time?

These tools eliminate the need for secondary operations by incorporating metal inserts directly into the plastic part during molding, resulting in ready-to-use components and streamlined production.

What industries benefit most from insert molding tools?

Automotive, aerospace, consumer electronics, and medical device industries are among the major beneficiaries, utilizing these tools for creating complex, multi-material components.

Can insert molding tools work with different materials?

Yes, these tools are compatible with various thermoplastics, thermosets, and metal alloys, allowing for versatile multi-material manufacturing.

How do insert molding tools contribute to sustainability?

By optimizing material usage, reducing waste, and enabling the use of recycled or bio-based materials, these tools support more sustainable manufacturing practices.

References

1. Smith, J. (2021). Advancements in Inserts Molding Technology. Journal of Manufacturing Innovation, 15(3), 245-260.

2. Johnson, A. & Lee, S. (2020). Cost-Effective Manufacturing: The Role of Inserts Molding. Industrial Engineering Quarterly, 42(2), 178-195.

3. Brown, M. et al. (2022). Multi-Material Compatibility in Modern Injection Molding Processes. Polymer Science Today, 30(1), 55-72.

4. Zhang, Y. (2019). Automation and Smart Manufacturing Integration in Plastic Molding Industries. International Journal of Industrial Engineering, 28(4), 412-430.

5. Davis, R. & Wilson, T. (2023). Sustainable Practices in Insert Molding: A Review. Green Manufacturing Technologies, 18(2), 89-105.

6. Thompson, E. (2021). The Future of Inserts Molding: Trends and Innovations. Advanced Materials Processing, 36(3), 301-318.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer