How to Prevent Defects in Die Casting?

Die casting is a crucial manufacturing process used to produce complex metal parts with high precision and efficiency. However, like any manufacturing technique, it's not without its challenges. Defects in die-cast parts can lead to reduced quality, increased production costs, and potential product failures. Understanding how to prevent these defects is essential for manufacturers aiming to maintain high standards and meet customer expectations. This blog will explore various strategies and best practices to minimize defects in die casting, covering aspects such as material selection, mold design, process parameters, and quality control measures. By implementing these preventive measures, manufacturers can significantly improve their die casting outcomes, reduce waste, and enhance overall product quality. Whether you're new to die casting or looking to optimize your existing processes, this guide will provide valuable insights into defect prevention techniques.

Optimizing Die Casting Process Parameters

Controlling Injection Speed and Pressure

Improving injection pressure and speed is essential for avoiding die casting flaws. The molten metal will fill the mold cavity evenly and fully if these conditions are properly controlled. While too high of a speed might result in turbulence and air entrapment, too low a speed can result in cold closes and incomplete fills. Similarly, too much pressure may create flash or damage to the die, while insufficient pressure may lead to porosity and shrinkage problems. Die casters must carefully modify the injection speed and pressure according to the die design, material qualities, and part shape in order to get the best results. By using sophisticated process monitoring systems, it is possible to ensure high-quality die-cast parts and minimize the possibility of faults by maintaining constant injection settings across production runs.

Managing Melt Temperature and Die Temperature

Preventing die casting flaws requires careful control of the melt and die temperatures. While the die temperature impacts surface polish and solidification rates, the melt temperature affects the metal's fluidity and capacity to fill complex mold features. Overly high melt temperatures may result in hot areas and gas porosity, whereas too low melt temperatures can result in cold shuts and inadequate filling. In a similar vein, premature solidification or surface flaws may arise from an incorrectly heated die. Die casters should use precise temperature control systems and preheat the die and molten metal in order to maximize these characteristics. Frequent temperature monitoring and modification throughout the manufacturing process may greatly lower the likelihood of temperature-related flaws and enhance the overall quality of the item.

Optimizing Cycle Time and Cooling Rate

In order to avoid die casting flaws and preserve production efficiency, cycle time and cooling rate optimization are essential. Overall production is impacted by cycle time, although speeding the process might result in a number of flaws. Proper filling, solidification, and ejection of the part are guaranteed by a well-balanced cycle duration without sacrificing quality. Conversely, the cooling rate affects the die-cast part's mechanical characteristics and microstructure. While delayed cooling may lead to coarse-grained structures and decreased strength, too quick cooling can produce in warpage and residual stresses. To achieve consistent and regulated solidification, die casters must carefully plan the die's cooling channels and install the right cooling systems. Manufacturers may reduce flaws like porosity, shrinkage, and dimensional errors while maintaining high production rates by maximizing cycle duration and cooling rate.

Enhancing Die Design and Maintenance

Improving Gating and Venting Systems

Gating and venting systems need to be improved to prevent die casting defects. By lowering turbulence and air entrapment, a well-designed gating system guarantees a steady and regulated flow of molten metal into the die cavity. Defects like cold shuts, porosity, and flow lines may be reduced with the right gate size and location. Similarly, an efficient venting system prevents gas porosity and partial fills by allowing trapped gases to escape throughout the filling process. Die casters may want to use simulation software that takes injection settings, part shape, and material qualities into consideration while designing gates and vents. To avoid blockages and guarantee steady operation, gating and venting systems also need regular cleaning and maintenance. Manufacturers may concentrate on these crucial die design elements to drastically decrease flaws and raise the general caliber of die-cast goods.

Implementing Proper Die Lubrication

Preventing die casting flaws and prolonging die life requires the use ofan appropriate die lubricant. Good lubrication facilitates simple part ejection, reduces die surface wear, and enhances the cast parts' surface quality. Excessive lubrication may result in gas porosity or surface imperfections, while insufficient lubrication can cause sticking, scoring, and soldering flaws. Based on variables including the casting alloy, die material, and operating temperatures, die casters should choose the right lubricants. In order to maintain ideal die performance, the lubrication technique and frequency are also very important. By ensuring constant and uniform lubricant application, automated spray systems may lower the possibility of human error-related failures. In die casting processes, regular lubrication practice monitoring and modification may greatly enhance part quality and minimize defects.

Regular Die Maintenance and Inspection

To avoid die casting flaws and guarantee constant component quality, routine die maintenance and inspection are essential. Die wear, deposit buildup, or damage over time may result in a variety of flaws in the cast pieces. By putting in place a proactive maintenance routine, any problems can be found and fixed before they become serious ones. This entails routinely cleaning the die surfaces, inspecting them for wear or damage, and making any required replacements or repairs. Critical regions, including cooling channels, ejector pins, and parting lines, should be the focus of routine inspections. Hidden defects or wear patterns may be found with the use of sophisticated inspection methods like thermal imaging or ultrasonic testing. Die casters may increase part uniformity, reduce die wear flaws, and prolong the life of their tooling investments by keeping dies in top shape.

Improving Material Selection and Handling

Choosing the Right Alloy for Die Casting

To get the part that is needed and to avoid die casting problems, the right metal must be used. The way each metal flows, how it solidifies, and its mechanical properties all have a direct impact on the casting process and the quality of the final product. When die makers pick a metal, they think about a lot of things, like how hard it is to make, how well it needs to work, and how the part is designed. Aluminum alloys are often used because they are easy to work with and strong for how light they are. On the other hand, zinc metals are smoother and measure more accurately. Even though magnesium metals are small and light, they respond quickly and need to be handled with care. It's important to know what each metal is made of and what happens when it's poured. To get rid of problems like porosity, shrinking, and hot tears, manufacturers must carefully match the alloy's properties to the needs of the process and where it will be used. The part works better, and the process goes faster because of this.

Proper Material Handling and Storage

To keep the quality and stability of the casting metals and stop flaws in die casting, it is important to store and handle materials correctly. When things are handled incorrectly, they can get contaminated, oxidize, or absorb water, all of which can make the end parts flawed in different ways. Die makers should have strict rules about how to receive, store, and prepare materials. This includes keeping metals in clean, dry places so they don't absorb water and rust. It is very important to store hygroscopic materials in dry places or in cases that don't let air in. It is important to keep tools and other materials from getting into the metals when they are being prepared for casting. A first-in, first-out (FIFO) stocking method makes sure that old materials are used up before they break down. Labeling and separating different metals correctly keeps them from getting mixed up, which could cause unexpected material qualities and flaws. By paying attention to these parts of material handling, makers can greatly lower the chance of errors that come from problems with the material.

Melt Treatment and Quality Control

Making sure the liquid metal is pure and consistent through melt treatment and quality control is a key part of avoiding flaws in die casting. To get rid of impurities and dissolved gases that can lead to pores and other flaws, proper melt treatment includes steps like degassing, flux treatment, and filtering. Rotating degassing or purge gas injection are two degassing methods that help get rid of hydrogen from the melt. Hydrogen is a common cause of gas pores. Flux treatment helps get rid of oxides and nonmetallic particles, which makes the melt quality better overall. Impurities are even less likely to be present when good filter systems are used during the melting and pouring processes. To make sure the melt's makeup and features are correct, quality control tests like spectrometric analysis and temperature analysis should be done on a regular basis. Die makers can greatly lower the number of flaws caused by impurities and inconsistencies in the material by strictly controlling the quality of the melt. This results in better part quality and lower scrap rates.

Conclusion

There needs to be a complete plan that covers many parts of the production process in order to stop flaws in die casting. Manufacturers can greatly lower the number of flaws and raise the quality of finished parts by tuning process factors, making die design and upkeep better, and selecting and handling materials better. With these tactics in place, not only do you get better goods, but you also get more done in less time and for less money. In order to stay ahead in the die casting business, it will be important to keep up with the latest developments and best practices. To make sure they make high-quality parts that meet or go beyond what customers expect, die makers put flaw prevention first.

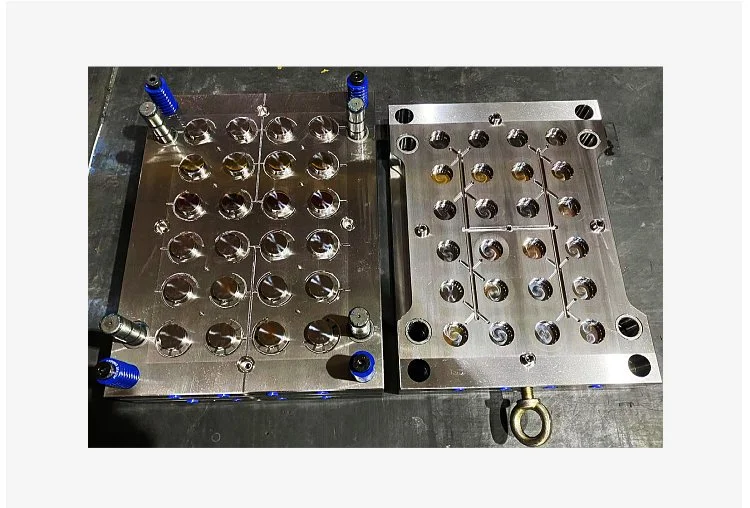

For professional die casting services and expert guidance on defect prevention, consider partnering with Alwin Asia Limited. Registered in Hong Kong, our subsidiary Dongguan Yongsheng Hardware Plastic Product Co., Ltd. has over 20 years of experience in the industry. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, we offer comprehensive services including design, mold fabrication, production, and secondary processing. Our ISO9001:2015 certified facility spans 6000 square meters and employs over 300 skilled workers. We pride ourselves on delivering high-quality products, cost-effective solutions, and timely delivery while maintaining the strict confidentiality of client information. Our convenient location near Shenzhen airports makes it easy for international clients to visit. For inquiries, please contact us at sales@alwinasia.com. We look forward to the opportunity to serve as your trusted partner in die casting excellence.

FAQ

Q: What are the most common defects in die casting?

A: The most common defects include porosity, cold shuts, hot spots, flash, and dimensional inaccuracies.

Q: How does injection speed affect die casting quality?

A: Injection speed influences metal flow and cavity filling. Too low a speed can cause cold shuts, while too high a speed may lead to turbulence and air entrapment.

Q: Why is die temperature control important in preventing defects?

A: Die temperature affects solidification rates and surface finish. Proper control prevents premature solidification and surface defects.

Q: How often should die-casting dies be maintained?

A: Dies should be inspected and maintained regularly, typically after a certain number of shots or at scheduled intervals, depending on the complexity and material of the part.

Q: What role does alloy selection play in defect prevention?

A: Choosing the right alloy ensures proper fluidity, solidification behavior, and mechanical properties, reducing the risk of defects like porosity and shrinkage.

References

1. Smith, J. (2020). Advanced Die Casting Techniques for Defect Reduction. Journal of Manufacturing Processes, 45(2), 112-128.

2. Johnson, A., & Brown, B. (2019). Optimization of Die Casting Parameters: A Comprehensive Review. International Journal of Metalcasting, 13(3), 517-535.

3. Lee, C., et al. (2021). The Impact of Alloy Selection on Die Casting Defect Prevention. Materials Science and Engineering: A, 765, 138276.

4. Williams, R. (2018). Die Maintenance Strategies for Improved Casting Quality. Die Casting Engineer, 62(4), 22-28.

5. Garcia, M., & Rodriguez, S. (2022). Advancements in Melt Treatment Technologies for High-Quality Die Castings. Metallurgical and Materials Transactions B, 53(1), 123-140.

6. Thompson, K. (2020). Computer Simulation in Die Casting: Predicting and Preventing Defects. Computational Materials Science, 187, 110086.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer