How to select materials for automotive parts?

It's important to choose the right materials for car parts and automotive parts so that they work well, last a long time, and are safe. There are always new problems and changes in the car business. Rules about the environment are getting stricter, so cars need to be smaller and use less gas. That makes it even harder to choose the right materials. Things that are used to make car parts and automotive parts should be chosen based on how well they work, how much they cost, how simple they are to make, and how they affect the world. The materials we will talk about range from simple metals to high-tech alloys. We will also talk about how progress in material science is changing the way cars and automotic parts will be made in the future. If you want to make good, reliable, and useful car parts and automotive parts, you should know how to choose the right materials, no matter what kind of person you are (worker, maker, or car fan).

Factors to Consider in Material Selection for Automotive Parts

Performance Requirements

Performance needs are the most important thing to consider when choosing materials for car parts. Engineers have to think about things like how strong something is, how long it will last, and how well it can handle different weather circumstances. For example, the materials used in engine parts have to be able to handle high temperatures and pressures. The materials used in the outside parts, on the other hand, have to be able to handle rust and UV light. The exact performance requirements will change based on what the part does and where it is located in the car. For instance, the materials that are used in safety-critical parts like brake systems have to meet very high standards for dependability. Another important thing to think about when choosing materials is how much they weigh. Lighter materials can help improve fuel economy and lower pollution. More and more, new high-strength steels, aluminum alloys, and carbon fiber composites are being used in auto parts to meet these performance needs while keeping the weight down.

Cost-Effectiveness and Manufacturability

When choosing materials for car parts, cost-effectiveness and ease of production are very important. High-performance materials may have better qualities, but they also need to be affordable enough to be made in large quantities. Engineers have to find a balance between how much raw materials cost and how much it costs to make finished parts out of them. Some materials may be less expensive to buy but more expensive to work with, while others may be more expensive to buy but easier to make. For example, thermoplastics are often used for automatic parts inside of cars because they are cheap and easy to shape. Metallic materials like aluminum, on the other hand, may be better for structural parts because they are strong and easy to work with. Innovative design and choice of materials can also help make something cost-effective by letting it combine multiple functions into a single part. Also, things like the cost of tools, the speed of production, and the ability to automate tasks all affect whether or not a material choice for automatic parts is economically viable.

Environmental Impact and Sustainability

Material choices for car parts are now more and more influenced by how they affect the environment and how long they last. As rules on pollution and reusing old cars get stricter, companies that make things must think about the whole span of the products they use. These include the natural costs of getting raw materials, preparing them, making things, using them, and then throwing them away or reusing them. The car business is becoming more interested in materials that can be recycled or come from natural sources. Bio-based plastics made from plant materials are being looked at as a more environmentally friendly option to standard plastics made from oil. Also, more and more recovered materials are being used to make car parts. Some makers even use recycled metals and plastics in their designs. The material's effect on the environment during the vehicle's use is also very important. Lightweight materials help the vehicle use less gas and produce fewer fumes. As cars become more electric, the environmental friendliness of battery materials and how easily they can be recycled are important things to think about when choosing materials for electric car parts.

Innovative Materials Revolutionizing Automotive Parts

Advanced High-Strength Steels

Today's advanced high-strength steels (AHSS) are strong, light, and easy to shape. They are changing the car business. Their ability to move better comes from having more complex microstructures than standard steels. More and more, AHSS is being used in building parts, body panels, and other places that are very important for road safety. Fewer gauges of steel can be used to make AHSS car bodies without lowering their strength. It loses a lot of weight for you. For environmental reasons, the fact that losing weight makes cars use less gas and waste less is beneficial. Ahss is also better because it works better when there is a crash. It's great for safety parts like bumper beams and side impact bars because of this. Craftsmen can shape AHSS and use it to create parts with more complicated shapes. With these changes, they can make cars in more ways, and the frames stay the same or get better.

Lightweight Alloys and Composites

When it comes to new materials for car parts, lightweight alloys and composites are setting the pace. When it comes to car parts, like engine blocks and body panels, aluminum alloys have become very popular. For the same strength and rust protection, these metals are a lot lighter than steel. Magnesium alloys have also gotten a lot of attention lately because they have an even lower density. However, they are hard to work with because they are expensive and hard to process. Another group of lightweight materials that is making its way into automotive parts uses is carbon fiber reinforced plastics (CFRP). As production techniques improve, CFRP is becoming easier to use for more common automotive parts. In the past, it was only used for high-performance and luxury vehicles because it was so expensive. If you want to make something new, these materials are great because they are strong for their weight and can be shaped into complicated shapes. Making automotive parts out of these lightweight materials not only helps them use less gas, but it also improves how they handle and perform.

Smart and Multifunctional Materials

It looks like smart and bendable materials will change the auto industry by making it easier to give parts of cars more improved functions. These things can change and fix themselves because they can respond to things like temperature, pressure, or electric fields. Metals that can remember their shape can be used to make car motors smaller and more efficient than regular mechanical systems. Piezoelectric materials can be used to collect energy, which means that waves from moving cars could be turned into useful power. There could be smart materials that change color or shape when they are hit. This would make things safer. Plastics and materials that can fix small harm on their own are also being made. This could make car parts last longer. Adding nanoparticles and nanomaterials to things makes them better in new ways, like making them stronger, better at handling heat in car parts, and more conductive.

Future Trends in Automotive Material Selection

Sustainable and Bio-based Materials

As part of its effort to have less of an effect on the environment, the car industry is putting more and more attention on bio-based and sustainable products. Because these materials come from green sources, they might have benefits like a smaller carbon footprint and being easier to recycle when they're no longer useful. Researchers are looking into using natural fibers like hemp, flax, and jute as supports in composite materials for inner parts. This could help the materials be lighter and better at blocking sound. Bio-based plastics, which come from things like corn starch or sugarcane, are being used in a wide range of non-structural parts. These materials not only make us less reliant on goods made from fuel, but they might also be biodegradable when the car is no longer useful. Bio-based materials with high performance are also being studied as a possible replacement for standard industrial plastics in more demanding car uses. As technology gets better and output gets bigger, these eco-friendly materials are likely to become more important when choosing materials for car parts.

Additive Manufacturing and Material Design

The process of choosing materials and designing car parts is changing because of additive manufacturing, or 3D printing. Advanced technology lets you create complicated automotic parts shapes that are tough or not possible to create using normal methods. Additionally, additive manufacturing lets you create designs for automotive parts that are light and have the best spread of materials. By doing this, the automotic part might be lighter while keeping or even better its performance. Adding automotic parts with internal grid structures or changeable density lets you control how much energy they absorb and how much heat they give off in new ways. Additionally, additive manufacturing lets you use new combinations of materials and functionally graded materials, which let you change how different parts of a single automotic part work. As a result, there are now more ways to combine several jobs into a single automotic part. This could cut down on the number of automotive parts needed and make assembly easier. Since additive manufacturing technologies keep getting better, allowing for faster production rates and larger automotic parts, they will probably have a bigger impact on the materials used and the way auto parts are designed.

Nanomaterials and Advanced Coatings

Nanomaterials and better finishes are two new material science findings that will have a big impact on the materials used to make car parts. Nanomaterials can make existing materials work better or create whole new material systems because of the unique properties they have at the nanoscale. Like, carbon nanotubes can be mixed with plastics to make materials that are very strong but also very light. These materials can be used to make car parts that support the body. Adding nanoparticles to car paints and coatings can make them scratch-proof and self-cleaning. A new type of improved protection for engine parts is ultra-thin ceramic covers. These can make them less likely to wear out and reduce friction, which makes the engine work better. Natural forms like lotus leaves are being used to make slippery coatings for windshields and other outside surfaces that will make them easier to see and need less cleaning. Two areas of study that are likely to become more important for making car parts work better, last longer, and be more useful are nanotechnology and covering technologies.

Conclusion

What you pick should have a thought for how it will work, how much it costs, how simple it is to make, and how it will impact the earth. New materials like smart materials, lightweight metals, composites, and better high-strength steels are changing how automatic parts are planned and built. The auto business is always changing. New finishes, materials that can be recycled and last a long time, and additive production methods will be used. These changes should make cars greener, safer, and smaller. They should also use less gas. If material science keeps growing, choosing the right materials for automatic parts will still be an important part of making the business grow and adapt to new needs.

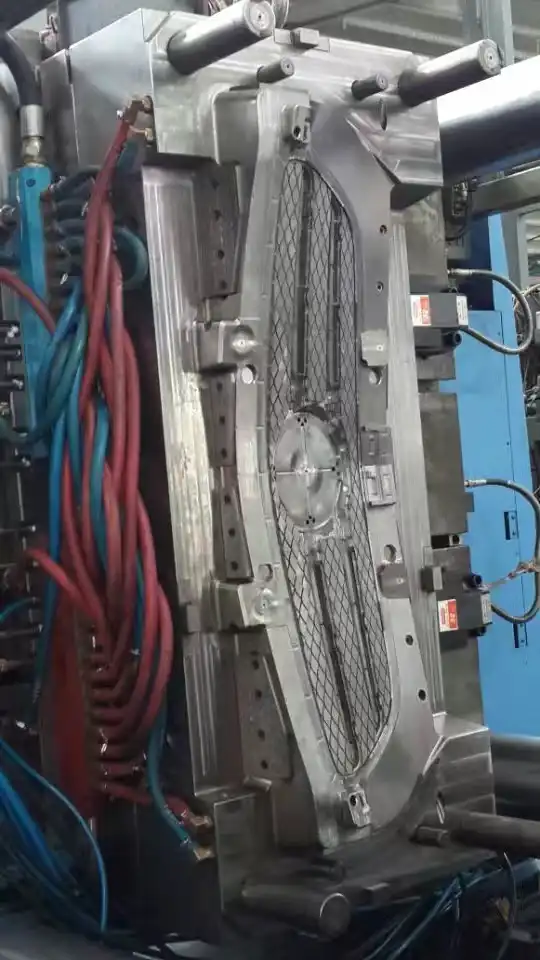

For more information on innovative materials and manufacturing solutions for automotive parts, please contact Alwin Asia Limited. Our subsidiary, Dongguan Yongsheng Hardware Plastic Product Co.,Ltd., has over 20 years of experience in plastic mould, die casting mould, and plastic products manufacturing. Located in Chang'an Town, Dongguan City, Guangdong Province, we offer comprehensive services including design, development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, and timely delivery makes us an ideal partner for your automotive part needs. For inquiries, please email us at sales@alwinasia.com.

FAQ

Q: What are the most important factors to consider when selecting materials for automotive parts?

A: Key factors include performance requirements, cost-effectiveness, manufacturability, and environmental impact.

Q: How are lightweight materials contributing to automotive design?

A: Lightweight materials like aluminum alloys and carbon fiber composites help improve fuel efficiency and reduce emissions while maintaining or enhancing performance.

Q: What role do advanced high-strength steels play in automotive parts?

A: Advanced high-strength steels offer superior strength and formability, allowing for weight reduction and improved safety in structural and body components.

Q: How is sustainability influencing material selection in the automotive industry?

A: Sustainability considerations are driving the adoption of recyclable materials, bio-based plastics, and materials with lower environmental impact throughout their lifecycle.

Q: What are smart materials, and how are they used in automotive parts?

A: Smart materials can respond to external stimuli, offering functionalities like self-healing and adaptive properties in various automotive applications.

References

1. Smith, J. D., & Johnson, R. K. (2020). Advanced Materials in Automotive Engineering. Elsevier Science.

2. Brown, A. C. (2019). Lightweight Materials for Automotive Applications. SAE International.

3. Chen, L., & Davis, M. E. (2021). Sustainable Materials for the Automotive Industry. Springer.

4. Thompson, S. T. (2018). Smart Materials and Structures in Automotive Design. Wiley-VCH.

5. Wilson, P. R., & Garcia, E. L. (2022). Additive Manufacturing in the Automotive Sector. CRC Press.

6. Anderson, K. M. (2020). Material Selection for Automotive Components: A Comprehensive Guide. Taylor & Francis.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer