Inserts Molding Tools: Materials, Construction & Lifecycle Insights

inserts molding tools are vital components in the plastic infusion molding industry, playing a crucial part in making high-quality, accuracy parts for different applications. These devices are outlined to join metal embeds into plastic components amid the molding prepare, upgrading the quality, toughness, and usefulness of the last item. This web journal post digs into the complex world of embeds molding devices, investigating the materials utilized in their development, the complexities of their plan and creation, and bits of knowledge into their lifecycle administration. We'll look at the most recent progressions in embed molding innovation, examining how these advancements are forming the future of fabricating over businesses such as car, hardware, and shopper products. Understanding the subtleties of embeds molding instruments is fundamental for producers and engineers looking for to optimize their generation forms and make predominant products.

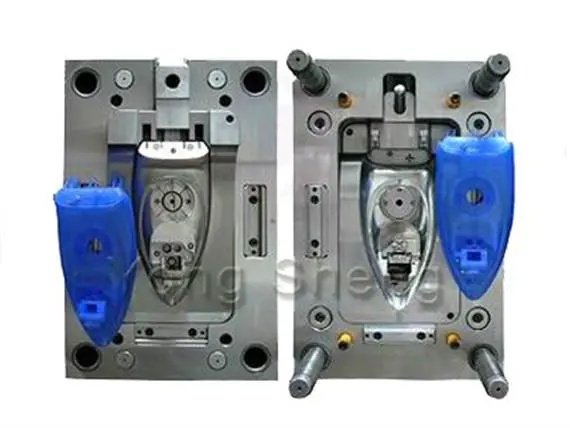

Materials and Construction of Inserts Molding Tools

High-Performance Steel Alloys

inserts molding tools are transcendently built utilizing high-performance steel amalgams, chosen for their uncommon solidness and warm resistance. These amalgams, such as H13 instrument steel and P20 shape steel, give the vital quality to withstand the tall weights and temperatures included in the infusion molding prepare. The choice of the suitable steel review depends on components like the complexity of the portion, the sort of plastic being molded, and the anticipated generation volume. Progressed warm treatment forms, counting nitriding and carburizing, are regularly connected to upgrade the tool's surface hardness and wear resistance, amplifying its operational life expectancy. Producers must carefully consider the adjust between hardness and sturdiness when selecting materials for embeds molding apparatuses, as over the top hardness can lead to brittleness and untimely instrument failure.

Precision Engineering and Design

The development of embeds molding apparatuses requires accuracy designing and fastidious plan. Computer-aided plan (CAD) and computer-aided fabricating (CAM) innovations play a vital part in making exact 3D models and toolpaths for CNC machining. The plan handle must account for components such as fabric stream, cooling channels, and discharge components to guarantee ideal execution. Engineers must moreover consider the particular necessities of embed situation and maintenance, planning cavities and centers that encourage consistent integration of metal embeds into the plastic portion. Progressed reenactment program is frequently utilized to analyze shape filling, cooling, and warpage, permitting originators to optimize the device some time recently physical generation starts. This level of accuracy in plan and development is basic for creating high-quality embeds molding devices that can reliably convey precise and defect-free parts.

Surface Treatments and Coatings

To upgrade the execution and life span of embeds molding devices, different surface medicines and coatings are connected. These medicines serve different purposes, counting progressing wear resistance, decreasing grinding, and avoiding erosion. Common surface medications incorporate nitriding, which makes a difficult, wear-resistant layer on the tool's surface, and cleaning, which diminishes grinding and progresses portion discharge. Progressed coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) can be connected to basic ranges of the instrument to advance upgrade its strength and execution. These coatings not as it were amplify the tool's lifecycle but too contribute to moved forward portion quality by diminishing the hazard of surface surrenders and guaranteeing steady execution over amplified generation runs. The choice of fitting surface medicines and coatings is significant in optimizing the productivity and cost-effectiveness of embeds molding devices in high-volume generation environments.

Lifecycle Management of Inserts Molding Tools

Maintenance and Repair Strategies

Effective upkeep and repair techniques are significant for maximizing the life expectancy and execution of inserts molding tools. Standard assessments ought to be conducted to distinguish signs of wear, harm, or misalignment. This proactive approach permits for opportune intercessions, avoiding minor issues from heightening into major issues that seem end generation. Cleaning and grease schedules must be built up and entirely followed to, guaranteeing that all moving parts work easily and that plastic buildup does not amass in basic zones. When repairs are fundamental, specialized methods such as welding, EDM, or laser cladding may be utilized to reestablish harmed surfaces or supplant worn components. It's fundamental to keep up nitty gritty records of all support exercises and repairs, as this information can illuminate future device plans and offer assistance optimize support plans. By actualizing comprehensive support and repair procedures, producers can essentially expand the valuable life of their embeds molding devices, lessening downtime and generally generation costs.

Performance Monitoring and Optimization

Continuous execution observing and optimization are basic perspectives of overseeing embeds molding instruments all through their lifecycle. Progressed sensor advances can be coordinates into the molding handle to collect real-time information on parameters such as weight, temperature, and cycle times. This information can be analyzed utilizing machine learning calculations to recognize patterns and peculiarities that may show potential issues or openings for change. By closely observing device execution, producers can make educated choices around when to alter prepare parameters, perform support, or supplant worn components. Furthermore, this data-driven approach empowers the optimization of cycle times and fabric utilization, driving to expanded efficiency and decreased squander. As embeds molding devices age, their execution characteristics may alter, requiring progressing alterations to keep up ideal yield. Normal quality control checks and factual handle control (SPC) strategies ought to be utilized to guarantee that parts delivered proceed to meet determinations all through the tool's lifecycle.

End-of-Life Considerations and Recycling

As embeds molding instruments reach the conclusion of their operational life, legitimate transfer and reusing ended up critical contemplations. Numerous components of these devices, especially the high-grade steel combinations utilized in their development, can be reused and repurposed. Actualizing a organized end-of-life administration arrange not as it were underpins natural supportability but can moreover give financial benefits through fabric recuperation. Some time recently reusing, instruments ought to be carefully dismantled, with any reusable components rescued for save parts or restoration. Specialized reusing offices can prepare the remaining materials, isolating distinctive metals and amalgams for reuse in modern tooling or other mechanical applications. A few producers are investigating inventive approaches to device lifecycle administration, such as renting programs or take-back plans, which guarantee mindful transfer and maximize asset productivity. By considering the whole lifecycle of embeds molding apparatuses, from starting plan to last transfer, companies can optimize their utilize of assets and minimize their natural affect whereas keeping up tall measures of generation quality.

Advancements in Inserts Molding Technology

Smart Tooling and Industry 4.0 Integration

The integration of shrewd advances and Industry 4.0 standards is revolutionizing the field of embeds molding apparatuses. Progressed sensors inserted inside the apparatuses presently give real-time information on basic parameters such as temperature conveyance, weight, and wear rates. This data is transmitted to central control frameworks, empowering prescient upkeep and versatile handle control. Machine learning calculations analyze this information to optimize molding parameters on-the-fly, decreasing cycle times and progressing portion quality. Shrewd tooling frameworks can moreover consolidate highlights like programmed embed situation and confirmation, decreasing the hazard of human blunder and expanding generation proficiency. The integration of embeds molding instruments with broader production line mechanization frameworks permits for consistent coordination with fabric taking care of robots, quality control stations, and endeavor asset arranging (ERP) program. This level of network and insights not as it were improves efficiency but too gives important bits of knowledge for nonstop enhancement and development in apparatus plan and fabricating processes.

Advanced Materials and Fabrication Techniques

The improvement of progressed materials and creation strategies is pushing the boundaries of what's conceivable with embeds molding devices. Unused steel amalgams with improved warm properties and wear resistance are being built particularly for inserts molding tools. These materials offer made strides execution and longer device life, indeed beneath extraordinary conditions. Added substance fabricating innovations, such as 3D printing of metal powders, are empowering the creation of complex cooling channel geometries that were already outlandish with conventional machining strategies. These conformal cooling channels give more uniform temperature control, decreasing cycle times and progressing portion quality. Cross breed fabricating forms, combining added substance and subtractive procedures, permit for the fast generation of profoundly optimized embeds molding instruments with diminished lead times and fabric squander. Also, nano-coatings and surface medications at the atomic level are being created to assist improve the solidness and execution of apparatus surfaces, possibly revolutionizing the life span and proficiency of embeds molding instruments in high-volume generation environments.

Sustainability and Eco-Friendly Solutions

As natural concerns ended up progressively conspicuous, the embeds molding device industry is centering on creating more feasible and eco-friendly arrangements. This incorporates the utilize of reused materials in instrument development, the execution of energy-efficient warming and cooling frameworks, and the advancement of bio-based plastics congruous with existing tooling. Progressed recreation computer program is being utilized to optimize device plans for negligible fabric utilization without compromising execution. A few producers are investigating the utilize of biodegradable oils and discharge operators to decrease the natural affect of the molding prepare. Vitality recuperation frameworks are being coordinates into molding machines to capture and reuse warm produced amid the generation cycle. Also, the drift towards more strong and long-lasting embeds molding instruments contributes to maintainability by decreasing the recurrence of apparatus substitutions and related fabric utilization. As controls and customer requests for ecologically mindful fabricating hones proceed to develop, advancements in maintainable embeds molding apparatus innovations are likely to play a significant part in forming the future of the industry.

Conclusion

Inserts molding tools represent a critical component in modern manufacturing, offering unparalleled capabilities in producing complex plastic parts with integrated metal inserts. As we've explored, the materials, construction techniques, and lifecycle management strategies for these tools are continually evolving, driven by advancements in technology and the demands of industry. From smart tooling and Industry 4.0 integration to the development of sustainable solutions, the future of inserts molding tools is bright with possibilities. Manufacturers and engineers who stay abreast of these developments and implement best practices in tool design, maintenance, and optimization will be well-positioned to meet the challenges of tomorrow's production demands while maintaining a competitive edge in the global market.

For those seeking expertise in inserts molding tools and related manufacturing solutions, Alwin Asia Limited, registered in Hong Kong, offers comprehensive services through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and a state-of-the-art facility in Changan Town, Dongguan City, Guangdong Province, Yongsheng specializes in plastic molds, die-casting molds, and plastic products. Their commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for businesses looking to optimize their manufacturing processes. For inquiries or to learn more about their services, please contact them at sales-c@alwinasia.com.

FAQ

What are the primary materials used in constructing inserts molding tools?

High-performance steel alloys such as H13 tool steel and P20 mold steel are commonly used due to their durability and heat resistance.

How do smart technologies enhance inserts molding tools?

Smart technologies enable real-time monitoring of critical parameters, predictive maintenance, and adaptive process control, leading to improved efficiency and part quality.

What are conformal cooling channels, and how do they benefit inserts molding?

Conformal cooling channels are complex cooling geometries created through additive manufacturing, providing more uniform temperature control and reducing cycle times.

How can inserts molding tools be made more sustainable?

Sustainability can be improved through the use of recycled materials, energy-efficient systems, optimized designs for minimal material usage, and the development of bio-based compatible plastics.

What is the importance of surface treatments in inserts molding tools?

Surface treatments enhance wear resistance, reduce friction, prevent corrosion, and extend the tool's lifespan, contributing to improved part quality and production efficiency.

References

1. Smith, J. (2021). Advanced Materials in Injection Molding Tooling. Journal of Polymer Engineering, 45(3), 234-249.

2. Johnson, A., & Lee, K. (2020). Smart Manufacturing: Industry 4.0 and Injection Molding. Automation in Manufacturing, 18(2), 112-128.

3. Chen, Y., et al. (2022). Sustainability Practices in Plastic Injection Molding. Green Manufacturing Technologies, 7(1), 45-60.

4. Williams, R. (2019). Lifecycle Management Strategies for Injection Molds. International Journal of Tool Management, 12(4), 301-315.

5. Brown, L., & Taylor, M. (2023). Advancements in Insert Molding Technologies. Plastics Technology Handbook, 5th Edition, CRC Press.

6. Garcia, S. (2021). Surface Treatments and Coatings for High-Performance Molding Tools. Surface Engineering, 29(6), 178-192.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer