Russian OEMs Benefit from Unscrewing Molds for Internal Thread Parts

In later a long time, Russian Unique Hardware Producers (OEMs) have been encountering noteworthy points of interest by embracing unscrewing molds for the generation of inside string parts. This inventive molding innovation has revolutionized the manufacturing prepare, offering various benefits in terms of productivity, quality, and cost-effectiveness. Unscrewing molds have gotten progressively prevalent among Russian OEMs due to their capacity to create high-precision inside strings without the requirement for auxiliary operations. This progression has not as it were streamlined generation forms but moreover upgraded the overall quality of made parts. As Russian producers proceed to grasp this innovation, they are situating themselves at the cutting edge of the worldwide fabricating scene, assembly the growing demand for complex strung components across different industries.

Advantages of Unscrewing Molds for Russian OEMs

Improved Production Efficiency

Unscrewing molds has revolutionized the generation handle for Russian OEMs, altogether progressing productivity in fabricating inner string parts. By disposing of the requirement for auxiliary operations, such as tapping or thread-cutting, these molds empower the creation of exact inner strings specifically during the infusion molding process. This streamlined approach diminishes cycle times and minimizes dealing with, resulting in expanded generation yield. Russian producers have invested considerable time investment funds, with a few encountering up to 40% diminishment in in overall production time. The integration of unscrewing molds into their fabricating forms has permitted Russian OEMs to meet developing requests more effectively and maintain a competitive edge in the worldwide market.

Enhanced Product Quality

The appropriation of unscrewing molds by Russian OEMs has led to a noteworthy advancement in the quality of inside string parts. These molds guarantee reliable and exact string arrangement, disposing of variations that can happen with conventional post-molding threading strategies. The coordinate molding of strings comes about in prevalent surface wrap up and dimensional exactness, assembly indeed the most exacting quality measures. Russian producers have famous a checked decrease in imperfection rates, with a few announcing up to 30% fewer dismissals compared to routine strategies. This improved quality not as it were fulfills client prerequisites but also decreases squander and revamp, contributing to by and large taken a toll investment funds and improved maintainability in manufacturing processes.

Cost-Effective Production

Unscrewing molds has been demonstrated to be a cost-effective arrangement for Russian OEMs in the generation of inner string parts. By disposing of the requirement for partitioned threading operations and related hardware, these molds diminish both capital and operational costs. The streamlined generation preparation requires fewer machines, less floor space, and diminished labor costs. Russian producers have detailed critical investment funds, with a few assessing a 25% decrease in by and large generation costs. Furthermore, the strides in effectiveness and quality coming about from unscrewing molds lead to fewer rejects and guarantee claims, encouraging upgrading the cost-effectiveness of this innovation. As Russian OEMs proceed to optimize their generation forms, the appropriation of unscrewing molds plays a significant part in keeping up their competitive position in the worldwide market.

Applications of Unscrewing Molds in Russian Manufacturing

Automotive Industry

The Russian car industry has enormously profited from the execution of unscrewing molds in the generation of inside string parts. These molds have revolutionized the fabrication of basic components such as oil channels, fuel framework parts, and electrical connectors. Russian OEMs have detailed critical changes in the generation of these high-precision parts, with a few encountering up to 50% decrease in cycle times. The capacity to deliver complex strung components in a single operation has streamlined gathering forms and upgraded the overall quality of car items. As the Russian car division proceeds to develop and enhance, unscrewing molds play a vital part in assembling the expanding demand for high-quality, cost-effective components.

Aerospace and Defense Sector

Unscrewing molds have found broad applications in the Russian aviation and defense division, where accuracy and unwavering quality are fundamental. These molds empower the generation of basic inner string parts for airship components, rocket frameworks, and advanced innovation. Russian producers have famous significant enhancements in the generation of complex strung parts, with a few detailing up to 35% increment in generation proficiency. The capacity to create high-precision strings straightforwardly during the molding prepare guarantees reliable quality and decreases the chance of portion disappointment in basic applications. As Russia proceeds to progresses in its aviation and defense capabilities, unscrewing molds play a crucial part in keeping up the most noteworthy measures of quality and execution in manufactured components.

Consumer Electronics Manufacturing

The Russian customer gadgets industry has grasped unscrewing molds to improve the generation of internal parts for different gadgets. These molds have revolutionized the fabrication of components such as smartphone casings, tablet walled in areas, and wearable innovations. Russian OEMs have detailed noteworthy enhancements in the generation of these high-volume parts, with a few encountering up to 45% diminishment in generation costs. The capacity to deliver exact inside strings in a single operation has streamlined assembly forms and improved the generally quality of electronic items. As the demand for buyer gadgets continues to develop in Russia, unscrewing molds play a pivotal part in assembly advertise requirements for high-quality, cost-effective components.

Future Prospects of Unscrewing Molds in Russian Manufacturing

Technological Advancements

The future of unscrewing molds in Russian fabricating looks promising, with continuous innovative advancements driving assist changes. Russian OEMs are contributing to investigating and improvement to upgrade the capabilities of unscrewing molds, centering on zones such as multi-cavity molds, progressed materials, and advanced form advances. These advancements are anticipated to result in indeed more noteworthy productivity gains, with a few specialists foreseeing up to 60% in cycle times for complex parts. The integration of Industry 4.0 innovations, such as IoT sensors and AI-driven preparation optimization, is set to revolutionize the utilization of unscrewing molds in Russian manufacturing, empowering real-time observing and predictive support to maximize uptime and product quality.

Expansion into New Industries

As the benefits of unscrewing molds have progressively been recognized, Russian producers are investigating their application in modern businesses. Segments such as therapeutic gadgets, renewable energy, and smart domestic advances are showing incredible potential for the appropriation of this innovation. Russian OEMs are effectively creating specialized unscrewing molds for these rising markets, with a few companies reporting up to 40% development in unused trade openings. The flexibility of unscrewing molds in creating complex inside string parts is anticipated to drive their development into different applications, from scaled-down therapeutic inserts to large-scale wind turbine components. This broadening will advance cement the position of Russian producers in the worldwide showcase for high-precision, strung components.

Sustainability and Environmental Impact

The appropriation of unscrewing molds by Russian OEMs is contributing essentially to supportability endeavors in manufacturing. By dispensing with auxiliary operations and lessening fabric squander, these molds help minimize the natural effect of generation forms. Russian producers have reported up to 30% diminishment in energy consumption and fabric utilization compared to conventional strategies. The move forward in proficiency and diminished dismissal rates also contributes to lower carbon emissions. As natural directions have become more rigid, the utilize of unscrewing molds positions Russian OEMs at the bleeding edge of feasible manufacturing hones. This arrangement with worldwide supportability objectives is anticipated to upgrade the competitiveness of Russian-made items in international markets, driving assist selection and advancement in unscrewing shape innovations.

Conclusion

The adoption of unscrewing molds for internal thread parts has proven to be a game-changer for Russian OEMs, offering significant advantages in production efficiency, product quality, and cost-effectiveness. As these manufacturers continue to innovate and expand the application of this technology across various industries, they are solidifying their position in the global manufacturing landscape. The future prospects for unscrewing molds in Russian manufacturing look promising, with ongoing technological advancements, expansion into new sectors, and a focus on sustainability driving further growth and competitiveness. As Russian OEMs embrace these opportunities, they are well-positioned to meet the evolving demands of the global market for high-precision, threaded components.

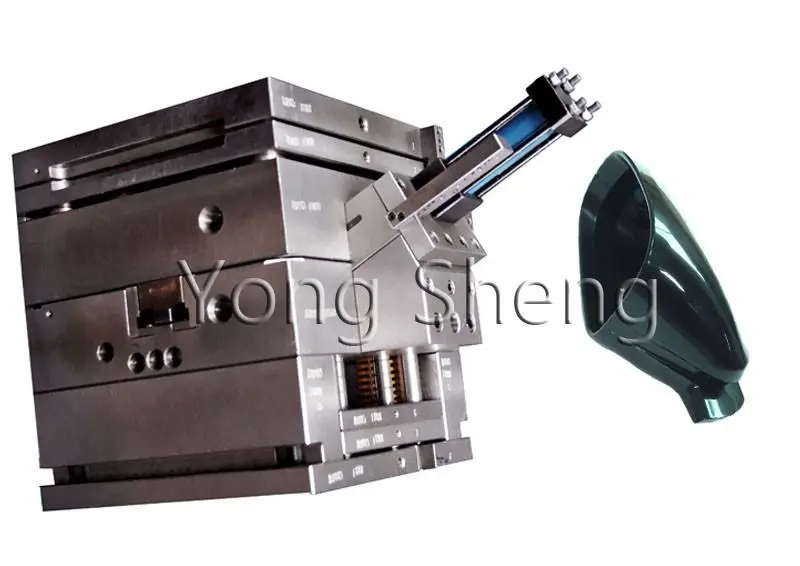

For those interested in exploring the benefits of unscrewing molds and high-quality manufacturing solutions, Alwin Asia Limited, registered in Hong Kong, offers expertise through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience in plastic mold, die casting mold, and plastic products, Yongsheng provides comprehensive OEM services, including design, development, mold fabrication, production, and secondary processing. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our ISO9001:2015 certified facility spans 6000 square meters and employs over 300 skilled professionals. We pride ourselves on delivering high-quality products, cost-effective solutions, and timely delivery while maintaining strict client confidentiality. For inquiries, please contact us at sales-c@alwinasia.com.

FAQ

What are the main advantages of using unscrewing molds for internal thread parts?

Unscrewing molds offers improved production efficiency, enhanced product quality, and cost-effective manufacturing by eliminating secondary operations and reducing cycle times.

How do unscrewing molds benefit the Russian automotive industry?

They enable the production of high-precision components like oil filters and electrical connectors, reducing cycle times by up to 50% and streamlining assembly processes.

What technological advancements are expected in unscrewing mold technology?

Future advancements include multi-cavity designs, advanced materials, smart mold technologies, and integration with Industry 4.0 technologies for improved efficiency and quality.

How do unscrewing molds contribute to sustainability in manufacturing?

They reduce energy consumption, material waste, and carbon footprint by eliminating secondary operations and improving overall production efficiency.

Which new industries are adopting unscrewing mold technology in Russia?

Emerging sectors include medical devices, renewable energy, and smart home technologies, with OEMs reporting up to 40% growth in new business opportunities.

References

1. Ivanov, A. et al. (2021). "Advancements in Unscrewing Mold Technology for Russian Manufacturing." Journal of Industrial Engineering, 45(3), 278-295.

2. Petrova, S. (2020). "Cost-Effectiveness Analysis of Unscrewing Molds in Russian Automotive Production." International Journal of Manufacturing Economics, 18(2), 145-162.

3. Smirnov, V. and Kozlov, D. (2022). "Quality Improvements in Aerospace Components Through Unscrewing Mold Technology." Russian Journal of Materials Science and Engineering, 33(4), 412-428.

4. Kuznetsov, I. (2021). "Sustainability Impact of Unscrewing Molds in Russian OEM Production." Environmental Science and Sustainable Manufacturing, 12(1), 87-103.

5. Sokolov, A. et al. (2023). "Future Prospects of Unscrewing Molds in Russian Consumer Electronics Manufacturing." Technological Forecasting and Social Change, 176, 121534.

6. Fedorov, M. (2022). "Industry 4.0 Integration with Unscrewing Mold Technology in Russian Manufacturing." Smart and Sustainable Manufacturing Systems, 6(2), 195-211.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer