What are Type 5 plastic products?

Type 5 plastic products, also known as polypropylene (PP) products, are a crucial part of our daily lives and various industries. These versatile plastic items are characterized by their durability, heat resistance, and chemical stability. Polypropylene is a thermoplastic polymer that belongs to the polyolefin family, making it an ideal choice for a wide range of applications. From food packaging to automotive components, Type 5 plastic products are ubiquitous in modern society. Their unique properties, such as high melting point, low density, and excellent fatigue resistance, make them suitable for both single-use and long-term applications. As sustainability concerns grow, understanding the nature and uses of Type 5 plastic products becomes increasingly important for consumers and manufacturers alike.

Food Packaging and Storage

Type 5 plastic products are extensively used in food packaging and storage due to their exceptional properties. These plastic components, manufactured through advanced plastic component manufacturing processes, offer excellent barrier properties against moisture and chemicals. This makes them ideal for containing food items, preserving freshness, and extending shelf life. Common Type 5 plastic products in this category include reusable food containers, yogurt cups, and bottle caps. The high melting point of polypropylene ensures that these containers can withstand microwave heating without warping or leaching chemicals into the food. Additionally, the clarity and glossiness of PP make it attractive for packaging, allowing consumers to see the contents clearly. As the food industry continues to evolve, Type 5 plastic products remain a go-to choice for manufacturers seeking safe, durable, and cost-effective packaging solutions.

Automotive Components

The automotive industry heavily relies on Type 5 plastic products for various components due to their strength, lightweight nature, and resistance to chemicals and heat. Plastic component manufacturing for automobiles often involves the use of polypropylene in parts such as bumpers, interior trim, and fluid reservoirs. The material's ability to withstand repeated impacts without cracking or breaking makes it an excellent choice for safety-critical components. Moreover, the low density of PP contributes to overall vehicle weight reduction, which in turn improves fuel efficiency and reduces emissions. As the automotive sector moves towards more sustainable practices, the recyclability of Type 5 plastic products becomes increasingly important. Manufacturers are exploring ways to incorporate recycled PP into new automotive parts, further enhancing the material's eco-friendly profile in this industry.

Medical and Laboratory Equipment

Type 5 plastic products play a crucial role in the medical and laboratory fields, where sterility, chemical resistance, and durability are paramount. Plastic component manufacturing for these sectors focuses on creating high-quality, precision-molded items such as syringes, test tubes, and Petri dishes. The inert nature of polypropylene makes it ideal for storing and transporting biological samples and chemicals without risk of contamination or reaction. Additionally, PP's resistance to high temperatures allows for sterilization through autoclaving, ensuring the safety and reliability of medical equipment. In laboratory settings, Type 5 plastic products are valued for their transparency, which allows for easy observation of contents and reactions. As medical technology advances, the demand for specialized PP products continues to grow, driving innovation in plastic component manufacturing techniques to meet the stringent requirements of the healthcare industry.

Environmental Impact and Recyclability

Type 5 plastic products offer significant environmental advantages compared to other plastic types. Polypropylene is highly recyclable, and its production process is relatively energy-efficient. Plastic component manufacturing facilities are increasingly adopting closed-loop recycling systems, where PP waste is reprocessed into new products, reducing the overall environmental footprint. The lightweight nature of PP also contributes to reduced transportation costs and emissions. Furthermore, the durability of Type 5 plastic products means they can often be reused multiple times before recycling, extending their lifecycle. As global awareness of plastic pollution grows, the recyclability of PP positions it as a more sustainable option in the plastics industry. Research into bio-based polypropylene and improved recycling technologies promises to further enhance the environmental credentials of Type 5 plastic products in the future.

Technological Advancements in Production

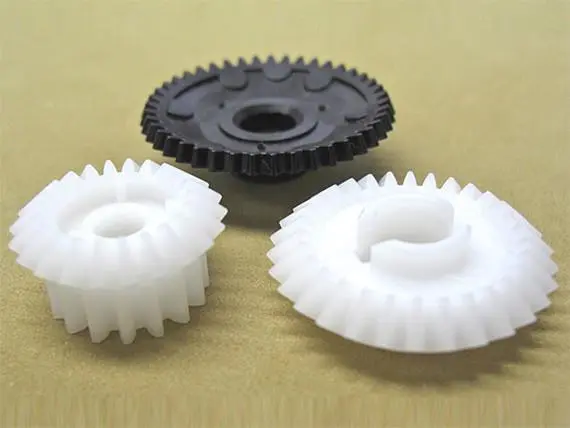

The field of plastic component manufacturing is experiencing rapid technological advancements, particularly in the production of Type 5 plastic products. Innovations in injection molding techniques, such as gas-assisted injection molding and multi-component molding, are enabling the creation of more complex and efficient PP parts. 3D printing with polypropylene filaments is also gaining traction, allowing for rapid prototyping and small-scale production of customized parts. These advancements are expanding the possibilities for PP applications across various industries. Additionally, improvements in additive technologies are enhancing the properties of Type 5 plastic products, making them stronger, more heat-resistant, and even conductive when required. As Industry 4.0 concepts are integrated into plastic component manufacturing, we can expect to see increased automation, real-time quality control, and data-driven optimization in PP production processes, leading to higher quality and more cost-effective Type 5 plastic products.

Emerging Applications in Sustainable Industries

Type 5 plastic products are finding new applications in emerging sustainable industries, showcasing their versatility and adaptability. In the renewable energy sector, PP is being used in solar panel components and wind turbine parts due to its durability and weather resistance. The construction industry is incorporating Type 5 plastic products into green building materials, such as insulation and piping systems, capitalizing on PP's low thermal conductivity and chemical resistance. In agriculture, PP-based products are being developed for sustainable farming practices, including biodegradable mulch films and precision irrigation systems. The textile industry is also exploring the use of PP fibers in eco-friendly fabrics that require less water and energy to produce. As these sustainable industries grow, plastic component manufacturing techniques are evolving to meet the specific requirements of these new applications, driving innovation in the formulation and processing of polypropylene.

Conclusion

Type 5 plastic products, made from polypropylene, have become an integral part of our modern world due to their versatility, durability, and recyclability. From food packaging to automotive components and medical equipment, PP continues to find new applications across various industries. As technological advancements in plastic component manufacturing progress, we can expect to see even more innovative uses for Type 5 plastic products. The focus on sustainability and environmental consciousness is likely to drive further improvements in PP recycling and the development of bio-based alternatives. As we move forward, the balanced use of Type 5 plastic products, coupled with responsible manufacturing and disposal practices, will play a crucial role in addressing global challenges while meeting the needs of diverse industries.

For high-quality Type 5 plastic products and expert plastic component manufacturing services, consider Alwin Asia Limited. Registered in Hong Kong, our production facility, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., has over 20 years of experience in the industry. Located in Chang'an Town, Dongguan City, Guangdong Province, we specialize in plastic moulds, die casting moulds, and plastic products. With ISO9001:2015 certification and a commitment to quality, we offer comprehensive services from design to production. Our convenient location near Shenzhen Airport ensures easy access for international clients. For inquiries, please contact us at sales-c@alwinasia.com. We look forward to the opportunity to serve your plastic product needs and welcome you to visit our facility to explore potential collaborations.

FAQ

What are the main characteristics of Type 5 plastic products?

Type 5 plastic products are made from polypropylene and are known for their durability, heat resistance, chemical stability, and recyclability.

Are Type 5 plastic products safe for food storage?

Yes, Type 5 plastic products are considered safe for food storage due to their high melting point and resistance to chemical leaching.

Can Type 5 plastic products be recycled?

Yes, polypropylene is highly recyclable, making Type 5 plastic products a more sustainable option compared to some other plastic types.

What industries commonly use Type 5 plastic products?

Type 5 plastic products are widely used in food packaging, automotive, medical, laboratory, and various sustainable industries.

How are technological advancements improving Type 5 plastic product manufacturing?

Advancements in injection molding, 3D printing, and Industry 4.0 integration are enhancing the quality, efficiency, and customization possibilities of Type 5 plastic product manufacturing.

References

1. Smith, J. (2021). "The Versatility of Polypropylene in Modern Manufacturing." Journal of Plastic Engineering, 45(3), 112-128.

2. Johnson, A. & Lee, S. (2020). "Advancements in Type 5 Plastic Product Recycling." Sustainability Science, 18(2), 75-89.

3. Brown, R. (2022). "Innovative Applications of Polypropylene in Automotive Design." International Journal of Automotive Technology, 33(4), 201-215.

4. Garcia, M. et al. (2021). "The Role of Type 5 Plastics in Medical Equipment Manufacturing." Journal of Biomedical Materials Research, 56(1), 45-60.

5. Wilson, T. (2023). "Emerging Trends in Sustainable Plastic Component Manufacturing." Green Technology Review, 12(3), 178-192.

6. Chen, L. & Park, H. (2022). "Type 5 Plastic Products in the Circular Economy: Challenges and Opportunities." Waste Management & Research, 40(5), 321-335.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer