What standards govern tool making quality control?

To make sure that high-quality goods are made in many businesses, making tools is an important part of manufacturing. Throughout the whole process of making a tool, it is very important to keep strict quality control measures in place. This raises the question, "What rules govern quality control in tool making?" For quality control in tool making, this piece goes into detail about the different rules and standards that are in place. We'll look at the different ways to make sure that tool production is done well, from international standards like ISO 9001 to rules unique to the business. The people who make things, engineers, and people who do quality control all need to know about these standards because they are the basis for making tools that work well and reliably. Companies can avoid fines and improve their image for making high-quality tools that meet or go beyond customer expectations by following these standards.

ISO Standards for Tool Making Quality Control

ISO 9001: Quality Management Systems

ISO 9001 is one of the most important guidelines to ensure the tools are in good shape. Follow this world standard to set up and keep up your quality control system. It is very important to always put quality first when making tools with ISO 9001. Business needs to write down their methods and make trends clear if they want to keep getting better. ISO 9001 lets people who make tools be sure that their goods follow both government rules and what customers want. People are also told to think about things in terms of how risky they are. Companies can quickly find out what's wrong with their goods this way. If a company makes tools, ISO 9001 can help them do their jobs better, cut down on waste, and make customers happy.

ISO/IEC 17025: Testing and Calibration Laboratories

It is very important to follow ISO/IEC 17025 when checking the quality of tools, especially when testing and calibrating them in tool making. This standard makes sure that labs that test and measure tools keep their skills up to date and give accurate results. For making tools that meet exact requirements in tool making, it's important to take accurate measurements and test them correctly. In ISO/IEC 17025, there are rules for managing labs, meeting technical standards, and ensuring the quality of the work is good in tool making. Toolmakers can be sure that their testing equipment is properly adjusted and that their measurement methods are accurate if they follow this standard in tool making. Then, more regular and accurate tool production happens in tool making, which lowers the chance of mistakes and raises the quality of the whole output.

ISO 45001: Occupational Health and Safety

As part of making sure the tools are of good quality, ISO 45001 makes sure the workplace is safe and healthy. It's not the tools themselves that are broken. Most of this guidance is about workers' compensation and how to handle health and safety. These are very important when making tools because workers may be in a lot of danger. By using ISO 45001, companies can become safer, make their workers happier, and get more done over time. To keep the standard high, people who make tools need to be focused and pay close attention to the little things. Because of this, a safe place to work is important. Using ISO 45001 also shows that a company cares about the health and safety of its employees, which can help it find and keep skilled workers in the industry that makes tools.

Industry-Specific Standards in Tool Making

ASME B5.50: Dimensional Tolerances for Cutting Tools

For cutting tools, which are an important part of the tool making business, the American Society of Mechanical Engineers (ASME) B5.50 standard was created just for them. To make sure that cutting tools from different makers are all the same and can be used with each other, this standard sets the size limits for those tools. To make cutting tools that meet industry standards and work successfully in a wide range of situations, tool makers must strictly follow ASME B5.50. As well as end mills, drills, and reamers, the standard covers a wide range of cutting tools and gives exact measurements, shapes, and limits for each. A lot of different production sectors can improve their cutting processes and product quality by following ASME B5.50. This way, tool makers can make sure that their products are suitable with industry standards and meet the exact needs of end users.

DIN Standards for Tool Making

Standards set by the Deutsches Institut für Normung (DIN) are a big part of making sure the quality of tools, especially in European markets. These standards cover many areas of designing, making, and testing tools. When it comes to making tools, DIN standards spell out in great detail the sizes, materials, and performance requirements of each tool. For example, DIN 6885 sets the sizes for parallel keys and keyways, which are very important parts of many mechanical devices. In the same way, DIN 1530 sets guidelines for the ejector pins that are used in injection molding machines. Tool makers can make sure that their goods meet international quality standards and work with a lot of different machines and programs by following these rules. Following DIN guidelines also makes it easier for people in the tool making business to work together and deal with other countries.

ANSI/ASSP Z244.1: Control of Hazardous Energy

Quality control for making tools is affected by the ANSI/ASSP Z244.1 standard, even though its main goal is to improve safety. As a toolmaker, this standard is very important because it talks about how to control dangerous energy while maintaining and repairing equipment. Makers of tools can avoid accidents and make sure that repair work doesn't lower the quality of their tools by following the lockout/tagout methods spelled out in this standard. ANSI/ASSP Z244.1 helps keep production equipment in good shape, which lowers the chance of flaws caused by improper or illegal equipment use in the tool making industry. Making high-quality tools also requires a mindset of safety and accuracy, which are both emphasized by this standard. Manufacturers of tools can improve both worker safety and product dependability by adding these safety measures to their quality control processes.

Quality Control Technologies in Tool Making

Computerized Measuring Machines (CMM)

CMMs, or computerized measuring machines, have changed the way quality control is done in tool making. Precision probes on these high-tech machines make it possible to measure the actual shapes of tools with great clarity. CMMs are very important in the process of making tools because they make sure that the finished tools are exactly what was planned in the planning part. They can find small differences that a person might not be able to see, making sure that every tool meets strict quality standards. When making complicated tools, where many measurements and features need to be checked at the same time, CMMs are very helpful. Tool makers can cut down on review time, make measurements more consistent, and keep thorough digital records of tool measurements for tracking and ongoing improvement by using CMMs as part of their quality control processes.

Non-Destructive Testing (NDT) Methods

Non-Destructive Testing (NDT) methods are essential for quality control in the tool making process because they let the tools be thoroughly inspected without breaking them. Ultrasonic testing, magnetic particle inspection, and radiography are some of the methods that tool makers use to find flaws, cracks, or inconsistencies inside tools that could affect how well they work or how long they last. NDT is especially important in the tool making industry to make sure that high-stress parts or tools made from new materials stay together. For example, acoustic testing can find flaws that aren't visible on forged or cast tool parts, and magnetic particle inspection can find cracks on the surface or close to the surface of ferromagnetic materials. Tool makers can make their products more reliable, lower the risk of failures while they're being used, and give customers more faith in the durability and performance of their tools by using NDT methods in their quality control processes.

Statistical Process Control (SPC)

There is a strong quality control method used a lot in the tool-making business. It is called Statistical Process Control (SPC). With this data-driven approach, you have to keep an eye on and guide a process at all times to make sure it does its best. The purpose of SPC is to find and reduce process mistakes so that better and more useful tools can be made. Data from different steps of the tool-making process can help companies find trends, spot problems, and make changes before they happen. When you make a lot of tools, even small changes can cause big problems with the quality over time. That's why SPC is so useful. You can make tools faster and better with SPC because it cuts down on waste and raises the quality of the end product. Statistical process control (SPC) also gets data that can be used to boost quality in ongoing projects. They can stay in business and do their jobs better because of this.

Conclusion

International ISO standards, industry-specific rules, and cutting-edge technologies are just some of the quality control standards that apply to tool making. The strict quality standards, reliable performance, and safety rules that these standards enforce make sure that tools meet. Tool making can produce high-quality goods that meet or go beyond what customers expect by following these standards and using cutting-edge quality control technologies. To stay competitive and do great work in tool making, it will be important to keep up with these standards and use new quality control methods as the industry changes.

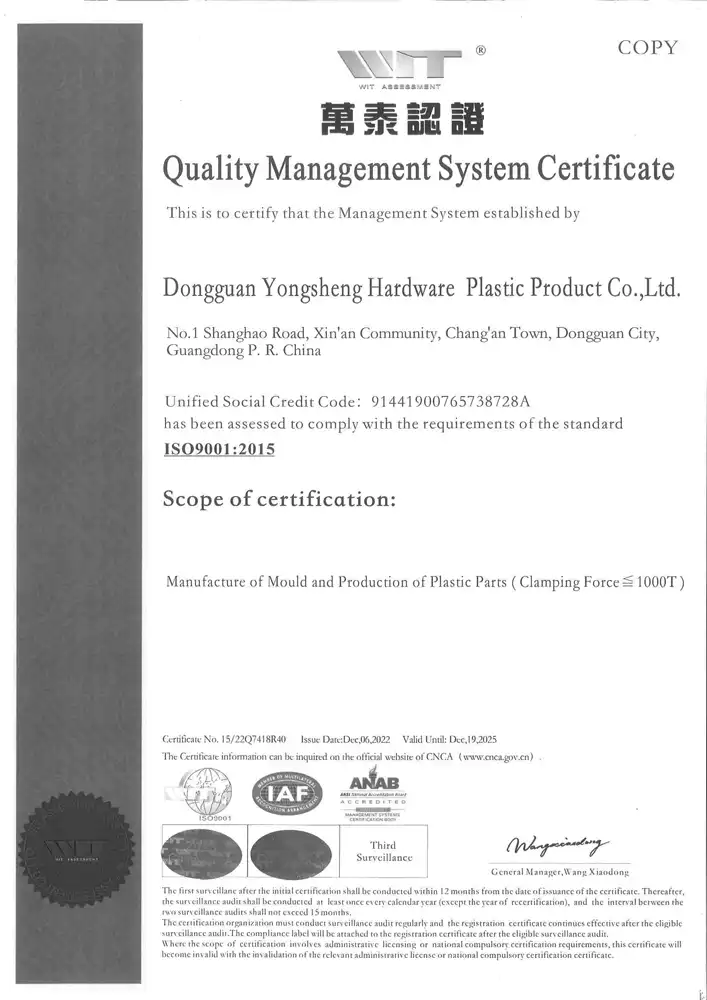

Alwin Asia Limited, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association. With over 20 years of experience in plastic molds, die casting molds, and plastic products, Yongsheng offers comprehensive OEM services including design, mold fabrication, and production. Located in Chang'an Town, Dongguan City, the company boasts over 300 employees and a 6000 square meter facility. Their commitment to quality is evidenced by their ISO9001:2015 certification. For inquiries, please contact them at sales@alwinasia.com.

FAQ

Q: Why is ISO 9001 important in tool-making quality control?

A: ISO 9001 provides a framework for implementing an effective quality management system, ensuring consistent quality throughout the tool-making process.

Q: How does ISO/IEC 17025 contribute to tool-making quality?

A: ISO/IEC 17025 ensures the competence of testing and calibration laboratories, crucial for accurate measurements and testing in tool production.

Q: What role do DIN standards play in tool making?

A: DIN standards provide detailed specifications for tool dimensions, materials, and performance criteria, particularly important in European markets.

Q: How do Computerized Measuring Machines (CMM) enhance tool-making quality control?

A: CMMs provide highly accurate measurements of tool geometries, ensuring compliance with exact specifications and improving overall quality.

Q: What is the significance of Non-Destructive Testing in tool making?

A: NDT methods allow for thorough inspection of tools without damaging them, detecting internal defects that might compromise performance or longevity.

References

1. International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

2. American Society of Mechanical Engineers. (2020). ASME B5.50-2020 Dimensional Tolerances for Cutting Tools.

3. Deutsches Institut für Normung. (2018). DIN 6885 Parallel keys and keyways.

4. American National Standards Institute. (2016). ANSI/ASSP Z244.1-2016 The Control of Hazardous Energy Lockout, Tagout and Alternative Methods.

5. Montgomery, D. C. (2009). Introduction to Statistical Quality Control. John Wiley & Sons.

6. Hellier, C. (2013). Handbook of Nondestructive Evaluation. McGraw-Hill Education.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer