How are Industry Parts manufacturing processes classified?

When you put business parts into ways of making things, you can get things done faster, better, and more easily. People who work in the field, like engineers, makers, and others, need to know about these industry parts in order to make smart choices about how to make things, which tools to use, and how to share resources. Some of the different ways that industrial parts are made depend on the materials used, the level of difficulty, the quantity needed, and the quality that is needed. These groups of methods are used by companies to ease the flow of work, cut costs, and meet changing customer wants. We can better understand the different ways that industrial parts are made if we know how hard industrial production is and how it affects different parts of the world economy.

Primary Manufacturing Processes for Industry Parts

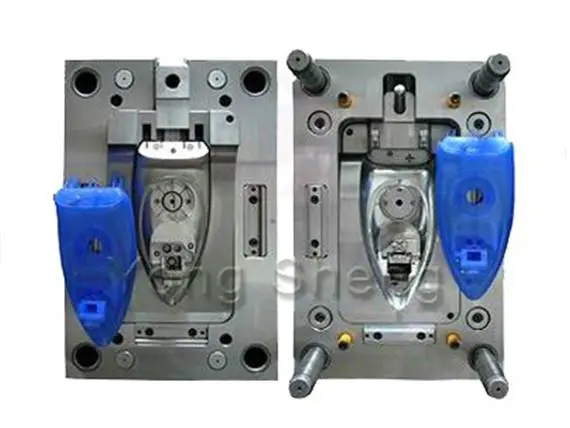

Casting and Molding Techniques

Molding and casting are basic manufacturing techniques that are used to make many parts for industries. In these methods, liquid metal is poured into a cast or hole to make the desired shape that is wanted. Casting and molding are very flexible processes that make it possible to make parts with complicated shapes and small details. Different casting methods, like sand casting, die casting, and investment casting, are used based on what the part needs. For items in the plastics business, molding methods like injection molding and compression molding are very common. With these methods, you can make a lot of parts quickly and cheaply, and the quality of the parts you make will always be the same. The casting or molding method is chosen based on the qualities of the material, the size of the part, and the amount of output that needs to be done. This is why they are so important for making a wide range of parts for industries.

Forming and Shaping Processes

It is very important to follow the steps for forming and shaping when making things out of metal or plastic. They only work if you use force or pressure to change the shape of the material. A few common ways to make things are to forge, cast, roll, and bend them. It depends on the type of material, the part's power, and how quickly it can be made. Each method has its own pros and cons. As an example, forging can be used to make industry parts that are very flexible, and extrusion is the best way to make forms that are long and continuous. A lot of the time, pressing and deep drawing are used to shape sheet metal into industry parts. This way of making things can be used to make complicated forms, and it can be highly automated for mass production. What makes the best making and shaping process different is the type of material, how complicated the part is, and what the production process requires. That's why they're so important for many kinds of businesses that need to make industry parts.

Machining and Material Removal

Machining and removing material are important steps in making accurate and complicated parts for industry. In these methods, material is taken away from a piece of work to get it to the right size, shape, and finish on the outside. Some common ways to machine are milling, turning, cutting, and grinding. CNC (Computer Numerical Control) cutting has changed this field completely, making it possible to make parts for industries that are very exact and can be made over and over again. Electrical Discharge Machining (EDM) and laser cutting are two examples of advanced machining methods that can be used to make complex shapes and tight specs out of different materials. Some of the benefits of material removal methods are high accuracy, the ability to work with a wide range of materials, and the freedom to build parts in different ways. However, compared to other ways of making things, they can take longer and waste more materials. When making high-precision parts for the industry, grinding and material removal are very important because the choice of process relies on things like the shape of the part, the qualities of the material, and the amount that needs to be removed.

Advanced Manufacturing Techniques for Industry Parts

Additive Manufacturing and 3D Printing

As a result of their extreme adaptability and design freedom, additive manufacturing and 3D printing have totally changed how business things are made. Using 3D computer models, these ways involve putting things together one layer at a time. Additive manufacturing techniques like stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS) can be used with various materials and for various uses. Benefits of additive printing for industry parts include shorter wait times, the ability to make complex forms, and low-cost production in small quantities. So that products can be made faster, these methods also let testing and creative design happen quickly. As technology gets better, aerospace, automotive, and medical parts are more often made by adding materials together using additive manufacturing. The ability to choose the best method for making parts for industry based on the material, the size of the part, and the amount being made is a benefit of adding additive manufacturing to the normal ways of making parts.

Joining and Assembly Processes

In business, joining and building methods are needed to make difficult industry parts and finished products. Using these ways, you can put together different industry parts or things to make a single building. Most of the time, people put industry parts together by brazing, welding, soldering, or gluing. Each method is better in some ways, such as making joints stronger, working better with certain materials, or producing industry parts more quickly, generally. For example, welding makes sure that the links between metal industry parts are strong and last a long time. Glue bonding, on the other hand, lets you join a lot of different types of industry materials together. A lot of different assembly methods are used to make flexible and easy-to-fix industry parts for industry. These include mechanical fixing and snap-fit assembly. Friction stir welding and laser welding are two advanced ways to put industry parts together that can be used to make good joints in tough industry materials. Different types of industry parts and kits need different ways to be joined and put together because of things like the performance standards, the shape of the industry parts, and the quality of the industry materials used.

Surface Treatment and Finishing

It is very important to know how to clean and treat the surface of industrial parts so that they look better and work better. In these ways, changing the way a part's surface looks will make it work better, last longer, or look better. People often anodize, heat treat, or case harden the surface to make it better. With these methods, industrial parts are made harder and less likely to rust. Things like grinding, painting, and finishing are used to finish parts and make their shape and surface better. New surface processes, such as plasma nitriding and physical vapor deposition (PVD) layers, can make high-performance industry parts more resistant to wear and better at how they work with other things. There are different ways to finish and treat the surface depending on the material, the part's use, and environmental concerns. These methods make business parts last longer and be of higher quality. They are often an important part of the making process.

Emerging Technologies in Industry Parts Manufacturing

Smart Manufacturing and Industry 4.0

Systems for making things are getting better and more efficient with the help of new technologies. In this way, smart production and ideas from Industry 4.0 are changing how business items are made. These methods use technologies like AI, the Internet of Things (IoT), and big data analytics to help people make better decisions and improve the way work gets done. As you make parts for businesses, smart manufacturing lets you see real-time information about production factors, plan ahead for equipment repairs, and change how the process works based on what you find. This makes the quality of the product better, cuts down on downtime, and gains overall equipment effectiveness (OEE). It is easier to make digital twins of parts and production lines with the help of Industry 4.0 concepts. This lets them be tested and made better before they are used. With things like output scale, technological readiness, and strategy goals in mind, smart manufacturing and Industry 4.0 technologies are growing in importance in the way parts for industries are made.

Nanotechnology in Manufacturing

Being able to change things at the atomic and molecular levels, nanotechnology has changed how industry parts are made. There are now ways to make things better in a lot of different fields that have never been seen before, thanks to this new field. Science can create new materials with nanotechnology that are stronger, lighter, and better at making things for industrial parts. Wear, rust, and tribological forces can be fought off much better on industrial parts that have nanocoatings and nanoparticles on their surfaces. Tiny things like carbon nanotubes and graphene are mixed with plastics to make strong industry parts that need to be able to move energy around. Nanotechnology can be seen in things like tiny additive production and ways that use nanoparticles to make it easier to connect industry parts together. This lets the business world do things that are hard and right. Production may or may not use nanotechnology, based on the type of material needed, the performance goals, and any possible legal problems. Using some new ideas in this area of making industry parts could be helpful.

Sustainable and Green Manufacturing

Because people are worried about the environment and the government is pushing for it, green and sustainable manufacturing methods are becoming more common in the parts business. All the way through the production process, these methods try to be as eco-friendly as possible, make good use of resources, and stick to the ideas of the cycle economy. The best use of products, less energy use, and as little trash as possible are all parts of sustainable production in the business world. Some green manufacturing methods, such as near-net shape making and additive manufacturing, use less energy and make less waste than traditional subtractive processes. To make closed-loop manufacturing systems work, recycled materials are used, and parts of the industry are made that are simple to get back. If you use eco-friendly cleaning and surface processes on your parts, you can also help protect the environment. Green and sustainable ways of making things are becoming more and more important as the industry parts production processes grow. They're used based on things like what the customer wants, what the government says, and what the company wants to go green with.

Conclusion

The classification of industry parts manufacturing processes encompasses a wide range of techniques, from traditional methods to cutting-edge technologies. As we have explored, these processes are categorized based on their primary functions, advanced applications, and emerging trends. The continuous evolution of manufacturing technologies offers new opportunities for innovation, efficiency, and sustainability in the production of industrial parts. By understanding and leveraging these diverse manufacturing processes, companies can optimize their production strategies, improve product quality, and meet the ever-changing demands of the global market. As the industry continues to advance, the integration of smart manufacturing, nanotechnology, and sustainable practices will play a crucial role in shaping the future of industry parts production.

For more information on industry parts manufacturing and our services, please contact Alwin Asia Limited. Our company, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a council member of the Dongguan City Hardware Machinery Mould Industry Association. With over 20 years of experience in plastic mould, die casting mould, and plastic products manufacturing, we offer comprehensive OEM services including design, development, mold fabrication, production, and secondary processing. Our factory, located in Chang'an Town, Dongguan City, Guangdong Province, spans 6000 square meters and employs over 300 skilled workers. We are ISO9001:2015 certified and committed to providing high-quality, cost-effective solutions with on-time delivery. To learn more about our services or to arrange a visit to our facility, please contact us at sales@alwinasia.com.

FAQ

Q: What are the main categories of industry parts manufacturing processes?

A: The main categories include primary processes (casting, forming, machining), advanced techniques (additive manufacturing, joining, surface treatment), and emerging technologies (smart manufacturing, nanotechnology, sustainable practices).

Q: How does additive manufacturing differ from traditional manufacturing methods?

A: Additive manufacturing builds parts layer by layer, allowing for complex geometries and reduced waste, while traditional methods often involve subtractive processes or material forming.

Q: What is the significance of Industry 4.0 in parts manufacturing?

A: Industry 4.0 integrates advanced technologies like IoT and AI to create smart manufacturing systems, improving efficiency, quality, and decision-making in parts production.

Q: How does nanotechnology impact industry parts manufacturing?

A: Nanotechnology enables the development of advanced materials and coatings, enhancing the properties and performance of industry parts at the atomic and molecular level.

Q: What are the benefits of sustainable manufacturing practices?

A: Sustainable practices minimize environmental impact, conserve resources, and promote circular economy principles, leading to more efficient and eco-friendly parts production.

References

1. Kalpakjian, S., & Schmid, S. R. (2020). Manufacturing Engineering and Technology. Pearson.

2. Groover, M. P. (2019). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons.

3. Gibson, I., Rosen, D., & Stucker, B. (2021). Additive Manufacturing Technologies. Springer.

4. Kusiak, A. (2018). Smart manufacturing. International Journal of Production Research, 56(1-2), 508-517.

5. Vollrath, I., & Kohl, H. (2017). Sustainable Manufacturing: Challenges, Solutions and Implementation Perspectives. Springer.

6. Tiwari, R., & Mishra, R. K. (2019). Advanced Manufacturing Technologies: Modern Machining Methods and Metrology. CRC Press.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer