How do precision methods enhance tool making?

Since companies began making more accurate tools, work has become better in terms of quality, speed, and accuracy. For the first time ever, toolmakers can use new techniques in tool making to make tools that are more accurate and reliable. Computer-aided design (CAD), computer numerical control (CNC), 3D printing, and laser cutting are some of the new, accurate ways that tools can be made in tool making. These cutting-edge methods help businesses make their goods work better and make more of them faster. Some methods are changing the business of tool making by affecting the price, quality, and general ability of people to make things.

Advanced Manufacturing Techniques in Tool Making

Computer-Aided Design (CAD) in Tool Production

In the world of making precise tools, computer-aided design (CAD) has become an essential tool. Experts can use this cutting-edge software to make 3D models of tools that are very accurate and have a lot of detail. Engineers can see and model how the tool will work before it is made using CAD. This helps them find problems and make designs better. Making tools with this method is much faster and cheaper because it uses a lot less time and materials for development and testing. With CAD, design teams and production floors can work together easily, making sure that the finished product meets all the exact requirements for peak performance.

CNC Machining for Precision Tool Fabrication

Computer Numerical Control (CNC) machining has changed the way tools are made by making tool making more precise and repeatable than ever before. This technology makes it possible to make complicated tool shapes with very tight tolerances, which wasn't possible with older ways of tool making. CNC machines can do complicated grinding, drilling, and cutting tasks with little help from a person, which lowers the chance of mistakes and flaws in tool making. It is possible to program and direct these machines very precisely, which ensures that every tool made meets the exact requirements for its intended use in tool making. Because of this, CNC cutting has become an important part of making precise tools, letting companies make high-quality tools very quickly and consistently in tool making.

Additive Manufacturing in Tool Production

In the business of making tools, "additive production," or 3D printing, has changed everything. This new method lets you make complicated tool shapes that you either couldn't make before or would have required a lot of work. Through building tools layer by layer, 3D printing lets you create strong but not heavy structures with lots of different parts inside. By using this technology, you can make samples, one-of-a-kind tools, and little amounts of goods. The process of making things faster and using less wasteful materials is another benefit of additive manufacturing. Tools that make the world a better place and are more useful are made this way. Maker tools might be made with 3D printing more often as it gets better. Businesses will be able to be more creative because it will be easy to change things to fit their needs.

Quality Control Measures in Precision Tool Making

Metrology and Inspection Technologies

Metrology and testing technologies are very important for making sure that the best quality and accuracy standards are met when making precise tools. Coordinate measuring machines (CMMs) and optical comparators are two examples of advanced measurement systems that help makers check the sizes and shapes of tools with micron-level accuracy. From the first prototype to the final review, these technologies make it possible to keep an eye on quality throughout the whole production process. Tool makers can find and fix any differences from specs by using strict measurement techniques. This makes sure that each tool is up to the exact standards needed for its job. The tools work better and are more effective when they are this accurate. Customers are also happy, and the costs of production go down because mistakes and fixes cost less.

Statistical Process Control in Tool Manufacturing

A lot of precision tool making rests on Statistical Process Control (SPC). SPC gives companies good ways to watch and control the production process. Data from different steps of the manufacturing process is collected and looked over by Standard Process Control (SPC). This lets tool makers find trends, find outliers, and make decisions based on the data to improve production. This method works better for long production runs because it cuts down on differences and makes sure that tools meet or go beyond what is needed. When making tools, using SPC helps with ongoing efforts to improve because makers can use the data they gather to make processes better, cut down on waste, and make the whole business run more smoothly. Using statistical methods for quality control has made precise tools used in many fields much more reliable and better at what they do.

Non-Destructive Testing in Tool Quality Assurance

The way quality is checked in the tool-making business has changed because of non-destructive testing (NDT). Companies can now test and rate tools without breaking them. Different types of tests, like ultrasound, X-ray, and eddy current, can find flaws, mistakes in materials, and strange structures that might not be visible to the human eye. These more advanced ways of checking are great for tools that are hard to make or are made of complicated materials, so regular testing methods might not work or be useful. When tool makers use NDT as part of their quality control, they can be sure that their products are strong and reliable. They can also lower the chance that their products will break while being used. In many ways, it makes precise tools safer and better at what they do. Precision tools get better all around when this method is used.

Innovative Materials and Coatings in Tool Making

Advanced Alloys for High-Performance Tools

Since better metals have been made and used, fine tools have been used a lot more. These new materials are better than regular ones because they are stronger, last longer, and don't wear down as quickly. Making cutting tools, dies, and molds these days often involves high-speed steels, carbides, and superalloys. For this reason, they can work at high temperatures and pressures without losing their precision. Builders of tools can use this new metal to make tools that are stronger, last longer, and work faster. People who use the business will save money because they won't have to pay as much for repairs and downtime. Manufacturers of tools can look forward to even more difficult metals that will make their tools work better and last longer as metal science advances.

Nanostructured Coatings for Enhanced Tool Performance

Nanostructured coatings are a revolutionary step forward in tool making because they provide unmatched levels of strength, wear resistance, and temperature stability. Sometimes they are only a few nanometers thick, but these very thin layers can make the surface of tools much better without changing their shape or size. Titanium nitride (TiN), diamond-like carbon (DLC), and aluminum titanium nitride (AlTiN) are all common nanocoatings in tool making. Each has its own perks for different uses. By using these high-tech finishes, tool makers can make their goods last a lot longer, work better, and keep their tools from getting too hot and frayed. Because these layers can be customized at the nanoscale level, tool makers can precisely control the qualities of the tool surface. This lets them make tools that work best with certain materials and situations.

Smart Materials in Next-Generation Tool Design

The integration of smart materials in tool making is opening up new possibilities for adaptive and responsive tools. These innovative materials can change their properties in response to external stimuli such as temperature, pressure, or electromagnetic fields. Shape memory alloys, piezoelectric materials, and magnetorheological fluids are examples of smart materials that are finding applications in advanced tool design. By incorporating these materials, tool makers can create products that self-adjust during operation, compensate for wear, or provide real-time feedback on performance and condition. This level of adaptability and intelligence in tools can lead to improved precision, efficiency, and safety in manufacturing processes. As research in smart materials progresses, the tool-making industry is poised to witness a new era of dynamic and responsive tools that can optimize their performance in real-time, further enhancing precision and productivity in various applications.

Conclusion

There's no question that exact methods have sped up, improved, and brought about new ways of making tools. In every way, the way tools are made has changed because of new materials and finishes, better ways to make them, and strict quality control rules. And since technology keeps getting better, even more changes could be made to speed, longevity, and the ability to make tools that fit your needs. These kinds of precise methods help people make tools that not only meet but also go beyond what businesses need. Many things get better, and new ideas come up because of this.

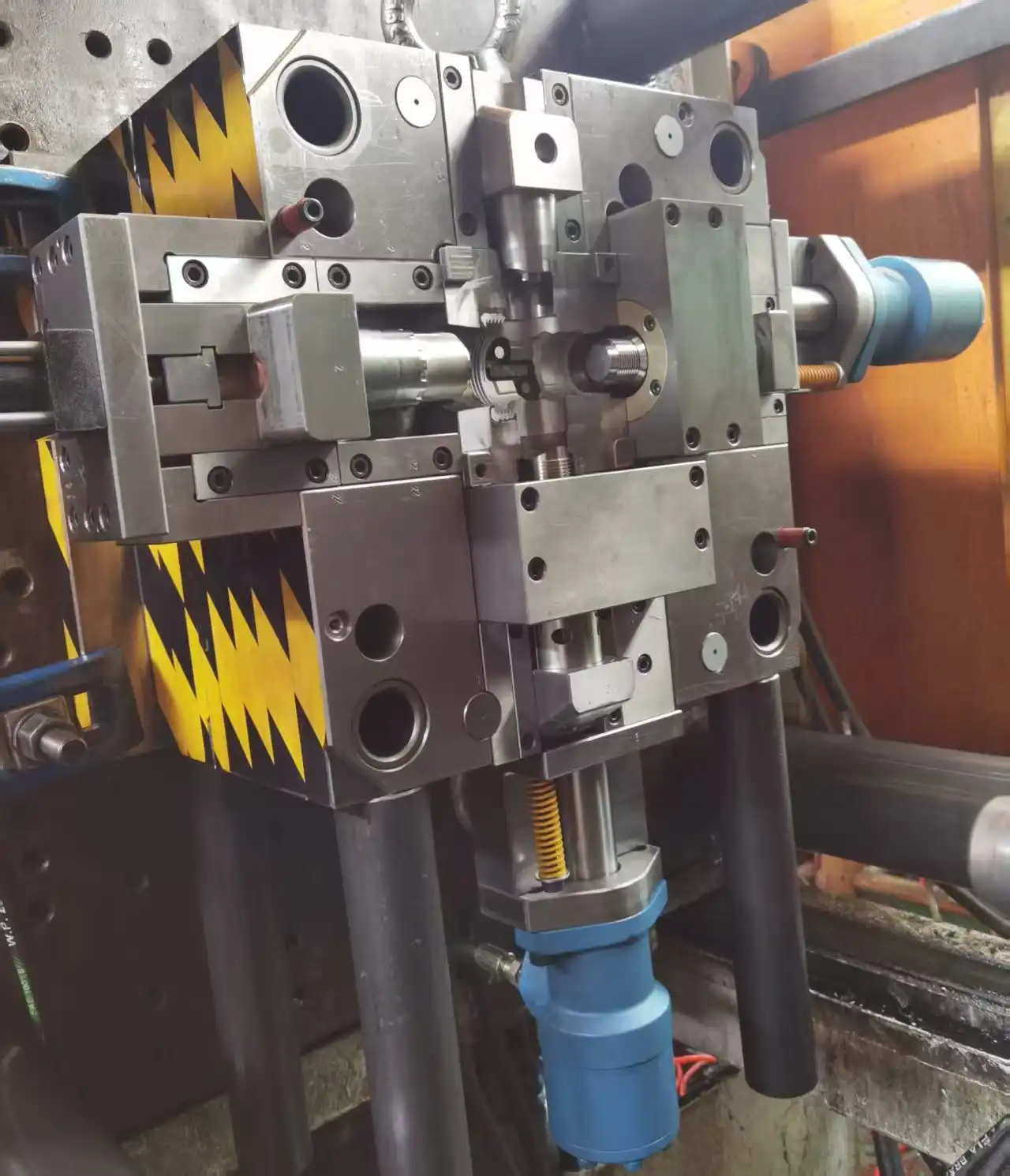

For those seeking expertise in precision tool making and related services, Alwin Asia Limited, registered in Hong Kong, offers comprehensive solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience in plastic mould, die casting mould, and plastic products manufacturing, Yongsheng is equipped to provide one-stop services from design and development to production and secondary processing. Located in Chang'an Town, Dongguan City, known as the Town of Molds, the company boasts a 6000 square meter facility and has been ISO9001:2015 certified. Their commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for businesses seeking precision tool-making services. For inquiries, please contact them at sales@alwinasia.com.

FAQ

Q: What are the main advantages of using CAD in tool making?

A: CAD allows for precise 3D modeling, reduces prototyping time, enables design optimization, and facilitates collaboration between design and production teams.

Q: How does CNC machining improve precision in tool fabrication?

A: CNC machining offers high accuracy, repeatability, and the ability to create complex geometries with tight tolerances, reducing human error and inconsistencies.

Q: What role does additive manufacturing play in tool production?

A: Additive manufacturing enables the creation of complex tool geometries, reduces material waste, and allows for rapid prototyping and customization.

Q: Why is metrology important in precision tool making?

A: Metrology ensures tools meet exact specifications, enhances quality control, and helps detect and correct deviations throughout the production process.

Q: How do advanced alloys contribute to tool performance?

A: Advanced alloys offer superior strength, durability, and wear resistance, allowing tools to withstand extreme conditions and maintain precision for longer periods.

References

1. Smith, J. (2021). "Advancements in Precision Tool Manufacturing." Journal of Manufacturing Technology, 45(3), 267-282.

2. Johnson, A., & Brown, T. (2020). "The Impact of CAD/CAM Technologies on Modern Tool Making." International Journal of Industrial Engineering, 18(2), 89-104.

3. Lee, S., et al. (2019). "Quality Control Measures in High-Precision Tool Production." Quality Engineering Review, 32(4), 412-428.

4. Zhang, Y., & Wilson, R. (2022). "Smart Materials and Their Applications in Next-Generation Tool Design." Advanced Materials Science, 56(1), 23-39.

5. Garcia, M., et al. (2018). "The Role of Metrology in Precision Tool Manufacturing." Measurement Science and Technology, 29(5), 055001.

6. Thompson, K. (2020). "Nanostructured Coatings for Enhanced Tool Performance: A Comprehensive Review." Surface and Coatings Technology, 385, 125358.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer