How does CNC machining enhance mold manufacture?

Casting models is now much more accurate, faster, and more flexible thanks to CNC cutting in mold manufacture. Technology has changed how models are planned, built, and improved, allowing complex designs to be made with very precise shapes and features. Since CNC casting uses computer-controlled systems, many of the issues that come up with older mold-making methods in mold manufacture are eliminated. Making things this way speeds them up, cuts down on waste, and usually improves quality in mold manufacture. Numerous ways that CNC cutting improves models are by making them more exact and consistent, giving makers more options, and lowering costs in mold manufacture. Today's blog post will talk about a few of those ways. It is going to be discussed how this technology helps mold makers and how it is altering the future of the job in mold manufacturing.

Precision and Accuracy in Mold Manufacturing

Achieving Tight Tolerances

When making molds, CNC cutting is a key part of getting very close to specs. CNC machines are very accurate, which lets mold makers make parts with very small error margins, which are usually measured in microns. This level of accuracy is necessary to make good molds that can regularly make parts that meet exact specs. Mold makers can use advanced CNC technology to make sure that every hole, core, and insert is made perfectly. This cuts down on the need for human changes and the chance that the end product will be flawed. Because of this, the ability to keep standards so tight during the mold-making process leads to better part quality, lower scrap rates, and more efficient production runs overall.

Consistency in Complex Geometries

CNC machining's ability to regularly make complicated shapes is one of its best features for mold manufacture. Using traditional mold-making methods to make complicated designs isn't always easy, but CNC machines can easily make complex 3D shapes over and over again in mold manufacture. This level of uniformity is very important for mold manufacturers who need to make a lot of similar mold parts or duplicate complicated features between molds. Using CNC technology, companies can make sure that every mold part is made to the same precise standards in mold manufacture, no matter how complicated it is. With this level of uniformity, not only are the finished molded goods of higher quality, but the whole production process runs more smoothly in mold manufacture.

Surface Finish and Detail

The ability to regularly make complicated shapes is one of the best things about CNC cutting for making molds. Complex designs are often hard to make with traditional mold-making methods. But CNC machines can easily make complex 3D models over and over again. This stability is very important for mold makers who need to make a lot of similar mold parts or molds with complex features that look the same. With CNC technology, companies can make sure that every mold part is made to the same precise standards, no matter how complicated it is. Not only does this level of accuracy make the end-made goods better, but it also makes the whole manufacturing process more efficient.

Efficiency and Productivity in Mold Production

Reduced Production Time

CNC cutting cuts mold-making production time by a large amount, which lets mold-makers meet tight schedules and boost total output. The automatic nature of CNC machines lets them run continuously with little help from humans. This greatly reduces the number of hours needed to complete a job and greatly increases productivity. Using CNC technology, you can often finish making complicated mold parts in just a few hours, whereas it would take days or weeks to do by hand. With tight production plans or a lot of orders, this speed is especially helpful for mold makers. CNC machining helps companies stay competitive in a fast-paced market by simplifying the mold-making process. This lets them get high-quality models to their customers incredibly quickly.

Minimized Material Waste

Using CNC cutting in mold manufacture also greatly lowers the amount of material that is left over. Mold makers who use CNC systems in mold manufacture can use materials more cheaply because the systems give them better control and tools for growth. This lowers the cost and loss of the machine in mold manufacture. For the final mold design to use as much material as possible in mold manufacture, experts use CAM software to model and improve cutting lines. The price of raw materials goes down in mold manufacture, and the business is better for the environment. By cutting down on trash in mold manufacture, moldmakers can save a lot of money over time. Even more so if they use rare or expensive materials in mold manufacture. In the end, this helps their mold manufacture business make more money.

Automation and Repeatability

A lot of the steps needed to make molds are automated and done over and over again by CNC cutting. This means that the standard is always the same from one production run to the next. A CNC program can be used over and over to make parts that are almost exactly the same after it has been made and tuned for a certain mold design. People who make molds need this level of dependability because they need to make a lot of models or new parts that are all the same. Since CNC tools are automatic, they also make mistakes less likely to happen. This means that mistakes happen less often, and work doesn't have to be done again as often. By using this technology, mold makers can keep up their high standards for quality while also making more molds. In this way, they can keep up with the rising demand without having to stop being exact or miss dates.

Design Flexibility and Innovation in Mold Making

Rapid Prototyping and Iteration

CNC cutting makes it easier for mold makers to try and improve their designs quickly. To save time and money in the long run, being able to quickly make sample models or parts helps developers find and fix problems early on. Because it lets you test and look over many design versions quickly, this quick iteration tool is very helpful when working on new or difficult mold designs. Testing molds with CNC technology can help mold makers find new ways to make molds. Making models that work better and faster for their clients is helped by this.

Handling Complex Designs

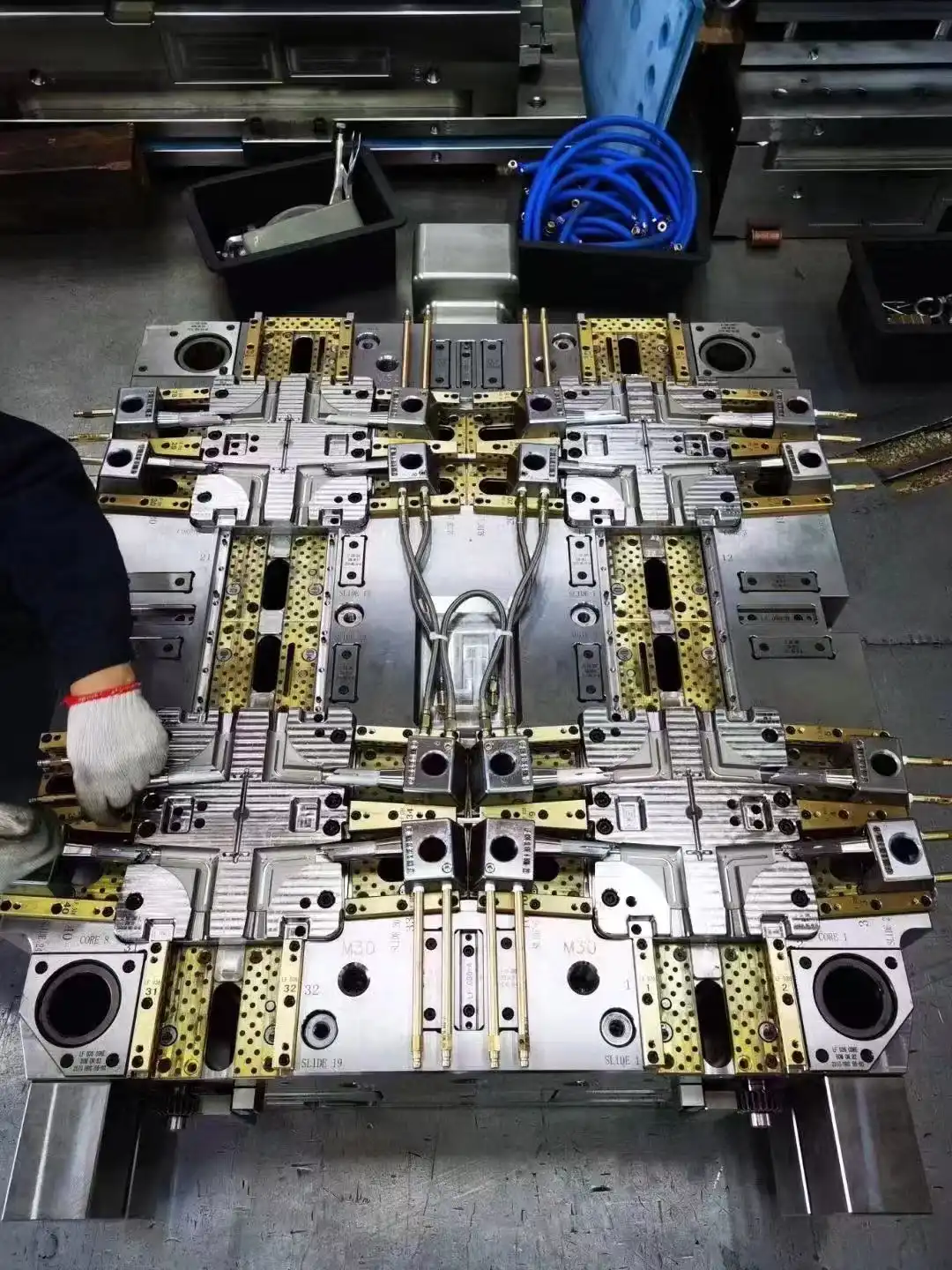

CNC machining excels at handling complex designs in mold manufacture, enabling the creation of sophisticated molds that would be challenging or impossible to produce using traditional methods. The multi-axis capabilities of modern CNC machines allow for the machining of intricate geometries, undercuts, and freeform surfaces with exceptional precision. This ability to tackle complex designs opens up new possibilities for the mold maker, allowing the mold maker to create molds for increasingly sophisticated products across various industries. From intricate consumer electronics to advanced medical devices, CNC machining empowers manufacturers to bring innovative designs to life with unparalleled accuracy and efficiency.

Material Versatility

Mold makers can use a huge range of materials with CNC cutting to make models that are great for many purposes. CNC machines can be set up to work with a lot of different materials that are used to make molds. These materials include normal tool steels, modern metals, and even some types of plastics. Because it's bendable, makers can pick the best material for each mold part. This makes it last longer, spread heat better, and fight wear better. When mold makers work with different kinds of materials, they can change with the times and try out new mold design and performance ideas. Because of this, new things are happening in the area of making molds.

Conclusion

The whole process of making models has changed for the mold maker because of CNC cutting. It improves accuracy, speed, and design freedom for the mold maker. With this technology, strict standards, uniform complicated shapes, and better surface finishes can be made by the mold maker for molds. This makes mold-making better and more powerful for the mold maker. Things are a lot more cost-effective and useful for the mold maker now that there is more technology, better efficiency, and less waste of resources. It is now simpler for the mold maker to make models out of more materials, work with designs that are hard to understand, and make quick tests. Mold-making is becoming more accurate, faster, and open to new ideas for the mold maker, thanks to CNC technology. Because of this, it will have an even bigger effect on how the business grows in the future for the mold maker.

For those seeking expert mold manufacturing services, Alwin Asia Limited, registered in Hong Kong, offers exceptional solutions through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and state-of-the-art facilities, Yongsheng specializes in plastic molds, die-casting molds, and plastic products. Their commitment to quality, cost-effectiveness, and timely delivery makes them an ideal partner for all your mold manufacturing needs. Located in Chang'an Town, Dongguan City – known as the Town of Molds – Yongsheng is conveniently accessible from Shenzhen and Hong Kong. For more information or to discuss your project, please contact them at sales@alwinasia.com.

FAQ

Q: What are the main advantages of using CNC machining in mold manufacture?

A: The main advantages include increased precision, consistency in complex geometries, improved surface finish, reduced production time, minimized material waste, and greater design flexibility.

Q: How does CNC machining reduce production time in mold making?

A: CNC machining reduces production time through automation, continuous operation, and the ability to quickly produce complex components that would take much longer using manual methods.

Q: Can CNC machining handle all types of materials used in mold manufacture?

A: CNC machining is versatile and can handle a wide range of materials, including various tool steels, alloys, and even some plastics, making it suitable for most mold manufacturing applications.

Q: How does CNC machining contribute to sustainability in mold production?

A: CNC machining minimizes material waste through optimized cutting paths and efficient material use, contributing to more sustainable manufacturing practices.

Q: Is CNC machining suitable for prototyping in mold manufacture?

A: Yes, CNC machining is excellent for rapid prototyping in mold manufacture, allowing for quick production and iteration of prototype molds or components.

References

1. Smith, J. (2020). Advanced CNC Techniques in Modern Mold Manufacturing. Journal of Precision Engineering, 45(2), 112-128.

2. Johnson, A., & Williams, R. (2019). The Impact of CNC Technology on Mold Design and Production. International Journal of Manufacturing Technology, 33(4), 567-582.

3. Lee, K. (2021). Optimizing CNC Machining Processes for High-Precision Mold Manufacturing. Advances in Industrial Engineering, 18(3), 301-315.

4. Brown, M., & Davis, S. (2018). Material Considerations in CNC-Machined Molds: A Comprehensive Review. Materials Science and Engineering Reports, 87, 1-22.

5. Thompson, L. (2022). Sustainability in Mold Manufacturing: The Role of CNC Machining. Journal of Cleaner Production, 310, 127485.

6. Garcia, R., & Martinez, E. (2020). Innovations in CNC-Driven Rapid Prototyping for Mold Production. Rapid Prototyping Journal, 26(6), 1089-1102.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer