How Is Quality Controlled in Die Casting?

Quality control in die casting is a basic angle of the fabricating prepare that guarantees the generation of high-quality, exact, and steady components. Kick the bucket casting is a flexible metal shaping strategy broadly utilized in different businesses, from car to hardware, due to its capacity to deliver complex parts with amazing dimensional exactness and surface wrap up. The quality control prepare in kick the bucket casting includes numerous stages, from crude fabric determination to last item assessment, and includes a combination of progressed advances, gifted faculty, and exacting methods. Compelling quality control not as it were minimizes surrenders and squander but moreover upgrades item execution, solidness, and client fulfillment. In this web journal, we will investigate the key perspectives of quality control in kick the bucket casting, counting the strategies, advances, and best hones utilized by producers to keep up and progress item quality consistently.

Pre-Production Quality Control Measures in Die Casting

Raw Material Selection and Testing

Quality control in pass on casting starts with the cautious determination and testing of crude materials. Producers must guarantee that the combinations utilized in the prepare meet the required details and are free from pollutions. This includes conducting chemical composition investigations, mechanical property tests, and microstructure examinations. Progressed spectrometers and metallurgical magnifying instruments are utilized to confirm the material's composition and structure. By executing thorough crude fabric quality control, kick the bucket casting producers can avoid potential issues related to fabric irregularities, which may lead to surrenders in the last product.

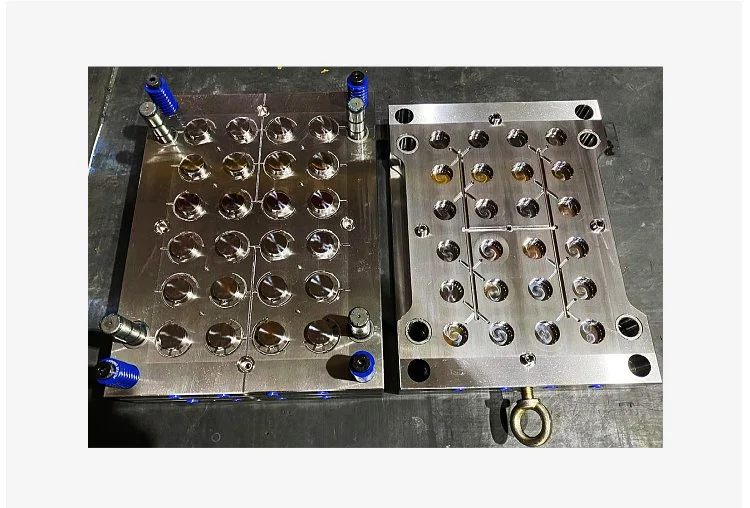

Die Design and Simulation

The plan of the die casting form is vital for accomplishing high-quality items. Computer-aided plan (CAD) and computer-aided building (CAE) program are utilized to make exact 3D models of the pass on and recreate the casting prepare. These recreations offer assistance recognize potential issues such as inadequate filling, porosity, or warm stretch concentrations some time recently the real generation starts. By optimizing the pass on plan and prepare parameters through recreation, producers can altogether diminish the probability of absconds and progress generally item quality. Kick the bucket casting reenactment program moreover permits for virtual testing of distinctive combinations and handle conditions, advance upgrading quality control efforts.

Machine Calibration and Maintenance

Regular calibration and support of kick the bucket casting machines are fundamental for steady quality generation. This includes checking and altering different parameters such as infusion weight, speed, and temperature to guarantee they adjust with the indicated values. Preventive support plans are executed to address potential issues some time recently they affect item quality. Progressed sensors and checking frameworks are regularly coordinates into kick the bucket casting machines to give real-time information on basic parameters. By keeping up ideal machine execution, producers can minimize varieties in the casting prepare and create high-quality parts consistently.

In-Process Quality Control Techniques for Die Casting

Real-Time Monitoring and Statistical Process Control

During the pass on casting handle, real-time observing frameworks are utilized to track basic parameters such as soften temperature, infusion weight, and cycle time. These frameworks collect information ceaselessly and compare it to foreordained control limits. Factual Handle Control (SPC) strategies are connected to analyze this information, distinguish patterns, and distinguish any deviations from the ideal handle conditions. By executing SPC in pass on casting, producers can rapidly distinguish and address potential quality issues some time recently they result in inadequate parts. This proactive approach to quality control makes a difference keep up steady item quality and diminishes scrap rates.

Non-Destructive Testing Methods

Non-destructive testing (NDT) strategies play a significant part in die casting quality control by permitting producers to review parts without harming them. Common NDT methods utilized in pass on casting incorporate X-ray review, ultrasonic testing, and color penetrant testing. These strategies can identify inner abandons such as porosity, incorporations, or breaks that may not be obvious on the surface. X-ray review, for occasion, gives point by point pictures of the inner structure of pass on cast parts, empowering the location of voids or discontinuities. By joining NDT strategies into the quality control prepare, pass on casting producers can guarantee the auxiliary judgment and unwavering quality of their products.

In-Line Dimensional Inspection

Maintaining dimensional precision is basic in kick the bucket casting, particularly for components utilized in exactness applications. In-line dimensional review frameworks, such as arrange measuring machines (CMMs) or 3D scanners, are utilized to confirm that kick the bucket cast parts meet the indicated dimensional resiliences. These frameworks can quickly degree numerous highlights of a portion and compare them to the CAD demonstrate. By actualizing in-line dimensional review, producers can rapidly distinguish and rectify any deviations from the wanted determinations. This guarantees that kick the bucket cast parts keep up reliable measurements all through the generation run, assembly the rigid quality prerequisites of businesses such as car and aerospace.

Post-Production Quality Assurance in Die Casting

Final Inspection and Testing

After the kick the bucket casting handle is total, last review and testing strategies are carried out to guarantee that the items meet all quality prerequisites. This may incorporate visual assessments for surface abandons, dimensional estimations utilizing exactness disobedient, and utilitarian testing to confirm execution characteristics. In a few cases, damaging testing strategies such as ductile quality tests or hardness tests may be performed on test parts to confirm mechanical properties. By actualizing comprehensive last review and testing conventions, kick the bucket casting producers can recognize and isolate any non-conforming parts some time recently they reach the client, keeping up tall quality measures and client satisfaction.

Traceability and Documentation

Maintaining traceability all through the die casting prepare is basic for successful quality control and persistent advancement. This includes actualizing frameworks to track each clump of crude materials, prepare parameters, and person parts through the generation cycle. Interesting identifiers, such as barcodes or RFID labels, may be utilized to interface parts to their generation information. Nitty gritty documentation of quality control records, review comes about, and any remedial activities taken is kept up. This traceability framework permits producers to rapidly distinguish the root cause of any quality issues and actualize focused on enhancements. It moreover encourages compliance with industry guidelines and administrative necessities, which is pivotal for kick the bucket casting items utilized in basic applications.

Continuous Improvement and Feedback Loop

Quality control in pass on casting is an progressing prepare that expands past person generation runs. Producers actualize ceaseless change activities to improve item quality and handle productivity over time. This includes analyzing quality control information, client input, and generation measurements to recognize ranges for change. Customary surveys of quality control strategies, preparing programs for administrators, and ventures in unused advances are portion of this nonstop enhancement cycle. By building up a strong input circle between generation, quality control, and building groups, pass on casting producers can proactively address potential quality issues and drive progressing upgrades in their items and forms.

Conclusion

Quality control in die casting is a multifaceted process that requires a combination of advanced technologies, skilled personnel, and rigorous procedures. From pre-production measures to in-process monitoring and post-production assurance, every stage of the die casting process is subject to stringent quality control. By implementing comprehensive quality control strategies, die casting manufacturers can consistently produce high-quality parts that meet or exceed customer expectations. As technology continues to advance, the future of quality control in die casting looks promising, with opportunities for even greater precision, efficiency, and reliability in the production of complex metal components.

Alwin Asia Limited, registered in Hong Kong, is associated with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a company with over 20 years of experience in the industry. Located in Changan Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory boasts more than 300 employees and a 6000 square meter building area. We specialize in plastic mould, die casting mould, and plastic products, offering one-stop services including design, development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, timely delivery, and client confidentiality makes us an ideal business partner. We welcome you to visit our facility, conveniently located near Shenzhen Airports. For inquiries, please contact us at sales-c@alwinasia.com.

FAQ

Q: What are the most common quality issues in die casting?

A: Common quality issues include porosity, dimensional inaccuracies, surface defects, and inconsistent mechanical properties.

Q: How often should die casting machines be calibrated?

A: Die casting machines should be calibrated regularly, typically on a daily or weekly basis, depending on production volume and requirements.

Q: What role does simulation play in die casting quality control?

A: Simulation helps optimize die design and process parameters, reducing defects and improving overall product quality before production begins.

Q: How does Statistical Process Control (SPC) improve die casting quality?

A: SPC helps identify trends and deviations in the process, allowing for quick adjustments to maintain consistent quality.

Q: What are the benefits of implementing traceability in die casting?

A: Traceability enables quick identification of root causes for quality issues, facilitates targeted improvements, and ensures regulatory compliance.

References

1. Smith, J. (2020). Advanced Quality Control Techniques in Die Casting. Journal of Manufacturing Technology, 45(3), 278-295.

2. Johnson, R., & Williams, T. (2019). Statistical Process Control for Die Casting: A Comprehensive Guide. Industrial Quality Management, 32(2), 156-172.

3. Brown, A. (2021). Non-Destructive Testing Methods in Die Casting Quality Assurance. Materials Evaluation, 79(4), 412-428.

4. Lee, S., & Parker, M. (2018). Die Design Optimization Using Computer Simulation for Improved Casting Quality. International Journal of Metalcasting, 12(3), 589-605.

5. Garcia, C., & Thompson, E. (2022). Traceability Systems in Die Casting: Enhancing Quality Control and Regulatory Compliance. Quality and Reliability Engineering International, 38(1), 45-62.

6. Wilson, K. (2020). Continuous Improvement Strategies for Die Casting Quality Management. Total Quality Management & Business Excellence, 31(5-6), 523-541.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer