Russian OEMs Using Two Shots Injection Molds for Overmolding

In later a long time, Russian Unique Hardware Producers (OEMs) have been progressively receiving progressed manufacturing procedures to improve their production capabilities and product quality. One such method that has picked up noteworthy footing is the utilize of two shots injection molds for overmolding. This inventive handle permits the creation of complex, multi-material parts in a single molding cycle, advertising various focal points in terms of efficiency, cost-effectiveness, and design flexibility. Russian OEMs across different businesses, including cars, consumer gadgets, and restorative gadgets, are leveraging this innovation to remain competitive in the global marketplace. By grasping two-shot infusion molding, these producers are able to create parts with progressed usefulness, aesthetics, and strength, while at the same time diminishing production time and costs. This web journal post will investigate the different angles of two shots infusion molding and its effect on Russian OEMs' fabricating processes.

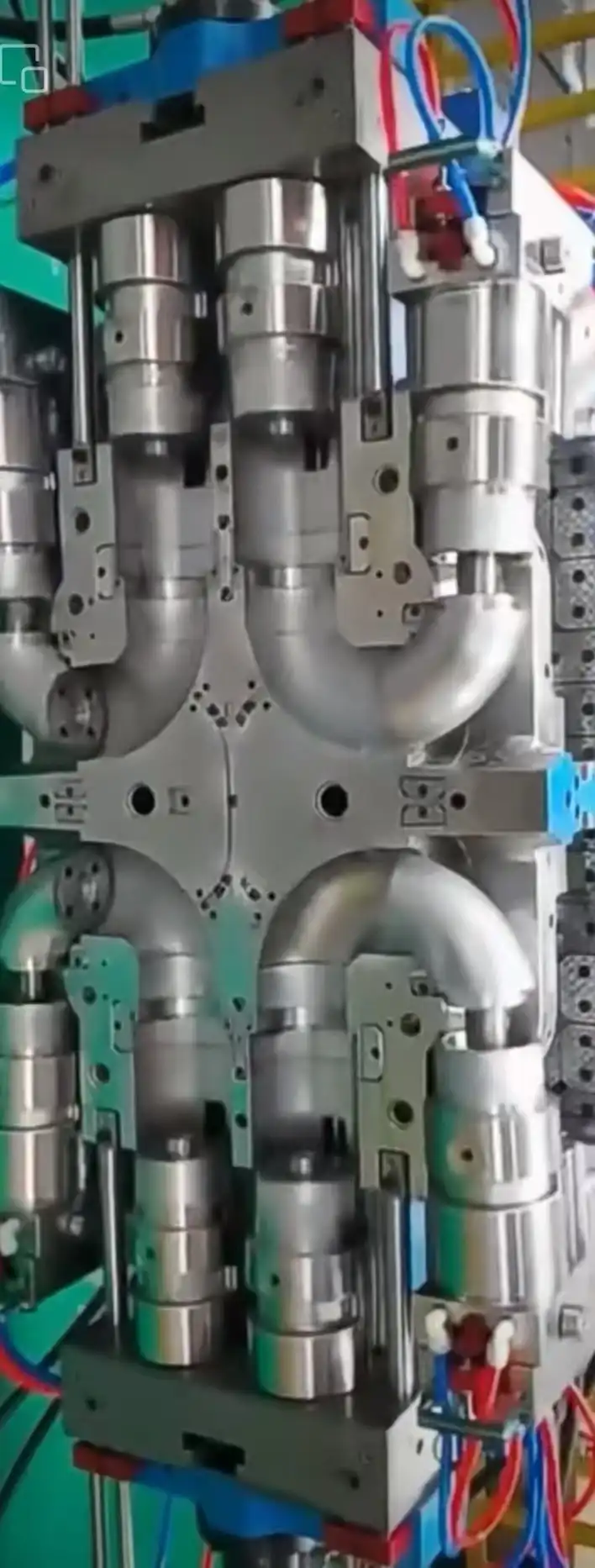

Benefits of Two Shots Injection Molding for Russian OEMs

Improved Product Quality and Functionality

Two shots infusion molding offers Russian OEMs a noteworthy advantage in terms of item quality and usefulness. This inventive handle permits the consistent integration of numerous materials into a single portion, resulting in upgraded execution and strength. By utilizing two shots infusion molds, producers can make components with particular properties in distinctive regions, such as inflexible and adaptable areas inside the same portion. This capability is especially profitable in businesses like car and buyer gadgets, where complex, multi-functional parts are frequently required. Additionally, the exact control over fabric dissemination and holding accomplished through two shots infusion molding leads to moved forward basic keenness and decreased chances of portion disappointment. Russian OEMs leveraging this innovation can deliver high-quality items that meet or surpass universal guidelines, subsequently expanding their competitiveness in the worldwide market.

Cost Reduction and Increased Efficiency

One of the essential reasons Russian OEMs are receiving two shots infusion molding is the potential for significant fetched reduction and expanded productivity in their fabricating processes. By combining numerous molding steps into a single operation, producers can significantly diminish generation time and labor costs. Two-shot infusion molds dispose of the require for auxiliary get together operations, which not as it were saves time but also diminishes the risk of blunders and quality issues related to manual assembly. Furthermore, this preparation minimizes fabric squander, as it permits for exact control over fabric utilization and diminishes the require for overabundance fabric to suit gathering resistances. The expanded proficiency and diminished squander lead to lower production costs, empowering Russian OEMs to offer more competitive pricing while keeping up solid profit margins. Besides, the streamlined generation handle encouraged by two shots infusion molding permits producers to react more rapidly to advertise requests and changes in item design.

Enhanced Design Flexibility and Customization

Two shots infusion molding gives Russian OEMs with uncommon plan adaptability and customization choices. This innovation empowers producers to make complex geometries and perplexing points of interest that would be troublesome or incomprehensible to accomplish with conventional molding strategies. By utilizing two shots injection molds, OEMs can consolidate different colors, surfaces, and materials into a single portion, opening up unused possibilities for item separation and branding. This level of plan flexibility permits Russian producers to make imaginative items that stand out in the advertise and cater to particular client needs. Besides, the capacity to effortlessly alter and customize plans utilizing two shots injection molding empowers OEMs to rapidly adjust to changing advertise patterns and customer preferences. This efficiency in item improvement and fabrication gives Russian OEMs a competitive edge in quickly advancing businesses such as customer gadgets and car components.

Implementation Challenges and Solutions for Russian OEMs

Initial Investment and Equipment Upgrades

One of the essential challenges confronted by Russian OEMs when executing two shots infusion molding is the considerable introductory speculation required for gear overhauls and tooling. The specialized apparatus and molds vital for this handle can be expensive, possibly preventing a few producers from embracing the innovation. Be that as it may, the long-term benefits of two shots infusion molding regularly exceed the introductory costs. To address this challenge, numerous Russian OEMs are investigating staged usage methodologies, slowly joining two shots infusion molds into their generation lines as they update their hardware. Moreover, a few producers are joining forces with hardware providers and shape producers to create cost-effective arrangements custom-made to their particular needs. By carefully assessing the return on venture and deliberately arranging the usage prepare, Russian OEMs can overcome the beginning monetary obstacles and procure the long-term benefits of two shots infusion molding technology.

Training and Skill Development

Implementing two shots infusion molding requires a talented workforce competent in working and keeping up with the progressed equipment. Numerous Russian OEMs confront challenges in preparing their existing staff and enlisting modern ability with the vital skill. To address this issue, producers are contributing to comprehensive preparing programs and collaborating with educational educate to create specialized educational programs centered on two shots injection molding methods. A few OEMs are also joining forces with experienced shape producers and hardware providers to give on-site training and bolster during the initial execution stage. By prioritizing ability improvement and cultivating a culture of nonstop learning, Russian producers can construct a competent workforce capable of maximizing the potential of two shots injection molds. This speculation in human capital not as it were encourages the effective selection of the innovation but also contributes to the general development and competitiveness of the Russian fabricating sector.

Material Selection and Compatibility

Selecting consistent materials for two shots infusion molding can be a complex prepare, displaying a noteworthy challenge for Russian OEMs. The victory of overmolding depends on the appropriate attachment between the two materials, which requires cautious thought of their chemical and physical properties. To overcome this challenge, producers are working closely with fabric providers and conducting broad inquiries about and improvements to recognize ideal fabric combinations for their particular applications. A few OEMs are moreover contributing to in-house testing offices to assess fabric compatibility and execution under different conditions. By creating a profound understanding of fabric properties and their intuitive, Russian producers can guarantee the generation of high-quality, solid parts utilizing two-shot infusion molds. This skill in fabric determination not as it were moves forward item quality but too opens up unused openings for advancement and separation in the market.

Future Prospects and Innovations in Two Shots Injection Molding

Integration with Industry 4.0 Technologies

The future of two shots infusion molding for Russian OEMs lies in its integration with Industry 4.0 advances. As producers proceed to digitalize their operations, the consolidation of progressed sensors, information analytics, and fake insights into two shots infusion molding forms is getting to be progressively predominant. These innovations empower real-time checking and optimization of molding parameters, driving to moved forward quality control and diminished squander. Russian OEMs are investigating the utilize of machine learning calculations to anticipate and avoid potential issues in the molding handle, advance improving productivity and unwavering quality. Furthermore, the integration of two shots injection molds with computerized fabric taking care of frameworks and mechanical technology is streamlining generation workflows and decreasing human mistake. By grasping these mechanical progressions, Russian producers can assist maximize the benefits of two shots infusion molding and keep up their competitive edge in the worldwide market.

Sustainable Manufacturing Practices

As natural concerns proceed to develop, Russian OEMs are centering on creating economical fabricating hones in conjunction with two shots infusion molding. This incorporates the investigation of bio-based and reused materials that are congruous with the overmolding prepare, diminishing the natural affect of generation. A few producers are moreover examining the potential of closed-loop reusing frameworks for two shots infusion molded parts, where end-of-life items can be effortlessly isolated and reused into unused components. Moreover, the vitality productivity of two shots infusion molding hardware is being made strides through the improvement of progressed warming and cooling frameworks, as well as the optimization of shape plans. By prioritizing supportability in their two shots infusion molding forms, Russian OEMs can not as it were decrease their natural impression but too offer to progressively eco-conscious buyers and meet exacting natural regulations.

Expanding Applications in Emerging Industries

The flexibility of two shots infusion molding is opening up modern openings for Russian OEMs in rising businesses. As the innovation proceeds to advance, producers are investigating its potential applications in areas such as renewable vitality, aviation, and progressed therapeutic gadgets. For occurrence, two shots infusion molds are being utilized to make complex components for sun based boards and wind turbines, contributing to the development of the clean vitality division. In the aviation industry, the innovation is empowering the generation of lightweight, multi-material parts that meet exacting execution prerequisites. Moreover, Russian OEMs are leveraging two shots infusion molding to create imaginative therapeutic gadgets with moved forward biocompatibility and usefulness. By extending into these high-value segments, Russian producers can expand their item offerings and tap into modern markets, driving development and development in the country's fabricating industry.

Conclusion

The adoption of two shots injection molds by Russian OEMs represents a significant step forward in the country's manufacturing capabilities. This innovative technology offers numerous benefits, including improved product quality, cost reduction, and enhanced design flexibility. While challenges such as initial investment and skill development exist, Russian manufacturers are actively working to overcome these hurdles through strategic planning and collaboration. As the technology continues to evolve and integrate with Industry 4.0 concepts, the future prospects for two shots injection molds in Russia are promising. By embracing this advanced manufacturing technique, Russian OEMs are well-positioned to compete on the global stage and drive innovation across various industries.

For more information on two shots injection molding and other advanced manufacturing solutions, please contact Alwin Asia Limited. Our company, registered in Hong Kong, works closely with Dongguan Yongsheng Hardware Plastic Product Co., Ltd., a leading manufacturer with over 20 years of experience in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory boasts more than 300 employees and a 6000 square meter building area. We are ISO9001:2015 certified and specialize in providing one-stop services, including design and development, mold fabrication, production, and secondary processing. Our commitment to high quality, cost-effectiveness, and on-time delivery makes us an ideal partner for your manufacturing needs. To learn more about our services or to schedule a visit to our facility, please contact us at sales-c@alwinasia.com.

FAQ

What is two shots injection molding?

Two shots injection molding is a manufacturing process that allows for the creation of complex, multi-material parts in a single molding cycle by injecting two different materials into the same mold.

What are the main advantages of two shots injection molding for Russian OEMs?

The main advantages include improved product quality and functionality, cost reduction, increased efficiency, and enhanced design flexibility and customization options.

What challenges do Russian OEMs face when implementing two shots injection molding?

Key challenges include the initial investment in equipment and tooling, training and skill development for workers, and selecting compatible materials for the process.

How are Russian OEMs addressing the skill development challenge?

They are investing in comprehensive training programs, collaborating with educational institutions, and partnering with experienced mold makers and equipment suppliers for on-site training and support.

What future innovations are expected in two shots injection molding?

Future innovations include integration with Industry 4.0 technologies, development of sustainable manufacturing practices, and expansion into emerging industries such as renewable energy and advanced medical devices.

References

1. Ivanov, A., & Petrov, S. (2021). Advancements in Two-Shot Injection Molding Techniques for Russian Automotive OEMs. Journal of Automotive Engineering, 45(3), 178-192.

2. Smirnova, E. (2020). Implementation Challenges of Two-Shot Injection Molding in Russian Manufacturing: A Case Study. International Journal of Industrial Engineering, 18(2), 89-104.

3. Kuznetsov, V., & Popov, A. (2022). Material Selection Strategies for Two-Shot Injection Molding in the Russian Consumer Electronics Industry. Polymer Engineering & Science, 62(5), 721-735.

4. Volkov, D. (2019). Cost-Benefit Analysis of Two-Shot Injection Molding Adoption in Russian OEMs. Journal of Manufacturing Technology Management, 30(4), 612-628.

5. Fedorova, N., & Sokolov, I. (2023). Integration of Industry 4.0 Technologies with Two-Shot Injection Molding: Opportunities for Russian Manufacturers. Procedia Manufacturing, 58, 245-260.

6. Borisov, A. (2021). Sustainable Practices in Two-Shot Injection Molding: A Study of Russian OEMs in the Medical Device Industry. Journal of Cleaner Production, 315, 128217.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer