How Russian Startups Leverage Custom Plastic Injection Molds for Rapid Scaling?

In the fast-paced world of new companies, Russian business visionaries are progressively turning to custom plastic injection molds as a key methodology for fast scaling. This inventive approach permits youthful companies to rapidly deliver high-quality, custom-designed plastic components fundamental for their products. By leveraging the adaptability and effectiveness of custom plastic infusion molding, Russian new businesses are able to repeat plans quickly, decrease production costs, and bring their developments to showcase quicker than ever some time recently. This strategy not as it were quickens item improvement but also empowers these developing businesses to compete viably with bigger, established companies. The utilize of custom plastic infusion molds is revolutionizing how Russian new companies approach fabricating, giving them the apparatuses required to turn their groundbreaking thoughts into unmistakable, market-ready items at a phenomenal pace.

Advantages of Custom Plastic Injection Molds for Russian Startups

Cost-Effectiveness and Scalability

Custom plastic infusion molds offer Russian new companies a cost-effective arrangement for scaling their production. By contributing to these molds, new companies can deliver huge amounts of plastic components with steady quality at a fraction of the fetched of conventional fabricating strategies. This versatility permits youthful companies to meet expanding demand without compromising on item quality or breaking the bank. The starting speculation in custom molds pays off rapidly as generation volumes increase, making it a perfect choice for new businesses looking to develop quickly. Furthermore, the capacity to deliver components in-house diminishes dependence on outside providers, giving new businesses more control over their supply chain and generation timelines.

Design Flexibility and Customization

One of the key preferences of custom plastic injection molds for Russian new businesses is the unparalleled plan adaptability they offer. Business visionaries can make complex and one-of-a-kind shapes that would be troublesome or outlandish to accomplish with other fabricating strategies. This adaptability permits new companies to separate their products in the advertise and make inventive arrangements custom-fitted to their particular needs. Custom molds, moreover, empower fast prototyping and product emphasis, permitting new companies to refine their products rapidly based on client input. This nimbleness in plan and generation is pivotal for new businesses working in competitive markets where the capacity to adjust and enhance rapidly can make the difference between victory and failure.

Improved Product Quality and Consistency

Custom plastic infusion molds essentially improve item quality and consistency for Russian new companies. These molds are precision-engineered to deliver components with tight tolerances and great surface wraps up, guaranteeing that each portion meets correct specifications. This level of consistency is pivotal for new companies creating high-tech or buyer items where quality is vital. The progressed item quality not as it were upgrades client satisfaction but also diminishes squander and the require for post-production finishing, advancing advances costs. Also, the solidness of custom molds implies they can deliver thousands or indeed millions of indistinguishable parts without corruption in quality, giving new businesses with a dependable manufacturing arrangement as they scale their operations.

Implementing Custom Plastic Injection Molds in Russian Startup Ecosystems

Collaboration with Local Mold Makers

Russian new businesses are progressively collaborating with nearby mold producers to actualize custom plastic injection molds in their production processes. This organization permits new companies to use the skills of experienced shape producers while keeping production near domestic. Neighborhood collaboration regularly comes about in quicker turnaround times, simpler communication, and the ability to make speedy alterations to shape plans. By working closely with form creators, new companies can guarantee that their custom molds are optimized for their particular items and production needs. This collaborative approach moreover fortifies the nearby economy and makes a difference in constructing a vigorous environment of manufacturing mastery within Russia, benefiting the whole startup community.

Integration with Advanced Manufacturing Technologies

The integration of custom plastic injection molds with progressive fabricating innovations is revolutionizing generation forms for Russian new businesses. Numerous are combining infusion molding with 3D printing, mechanical autonomy, and IoT-enabled checking frameworks to make savvy, proficient generation lines. This integration permits real-time quality control, prescient support, and data-driven optimization of the molding prepare. By leveraging these progressive innovations, new businesses can accomplish higher levels of computerization, decrease human error, and move forward by and large generative proficiency. The combination of custom molds and cutting-edge fabricating tech positions Russian new businesses at the bleeding edge of advancement, empowering them to compete on a worldwide scale.

Training and Skill Development

As the selection of custom plastic infusion molds develops among Russian new businesses, there is an expanding focus on preparing and ability improvement in this field. Numerous new businesses are contributing to their workforce, giving specialized training in business planning, operation, and upkeep. This upskilling activity guarantees that representatives can work with these progressed manufacturing devices, maximizing the benefits of custom molds. Also, organizations with instructional teaching are being shaped to make programs that educate on the most recent infusion molding procedures and advances. By cultivating a talented workforce, Russian new companies are not as it were making strides in their capabilities but also contributing to the advancement of a strong talent pool in the country's manufacturing sector.

Future Prospects and Challenges for Russian Startups Using Custom Plastic Injection Molds

Expanding into New Markets and Industries

The appropriation of custom plastic infusion molds is opening unused entryways for Russian new companies, permitting them to expand into different markets and businesses. With the capacity to deliver high-quality, custom components at scale, these new companies are no longer restricted to their introductory target markets. Numerous are finding openings in divisions such as car, medical devices, and consumer hardware, where precision plastic parts are in high demand. This broadening not as it were decreases the hazard for the new companies but also drives advancement as they adapt their innovations to modern applications. The adaptability of custom molds empowers Russian new businesses to rapidly adapt and seize opportunities in rising markets, situating them for long-term development and success in the worldwide economy.

Sustainability and Eco-Friendly Practices

As natural concerns have progressively become critical, Russian new businesses utilizing custom plastic injection molds are centering on sustainability and eco-friendly homes. Numerous companies are testing with biodegradable plastics and reused materials in their molds, pointing to decreasing their environmental impact. The exactness of custom molds also permits the creation of lighter, more effective items that utilize less fabric. A few new companies are actualizing closed-loop reusing frameworks in their generation offices, reusing scrap fabric from the molding process. These activities not as it were offer to ecologically cognizant shoppers but also frequently result in taking a toll on investment funds and moving forward proficiency. By grasping feasible homes, Russian new businesses are situating themselves as dependable trailblazers in the global market.

Overcoming Regulatory and Economic Challenges

Russian new companies leveraging custom plastic infusion molds confront different administrative and financial challenges that they must explore. Remaining compliant with advancing natural controls and universal exchange arrangements is significant for those looking to grow inclusively. Numerous new businesses are proactively working with administrative bodies to guarantee their manufacturing processes meet or surpass benchmarks. On the financial front, changes in crude fabric costs and money trade rates can affect generation costs. To moderate these dangers, a few new businesses are expanding their provider base and investigating supporting techniques. Furthermore, the progressing advancement of Russia's startup biological system and manufacturing framework presents both opportunities and obstacles. By remaining dexterous and versatile, these new companies are working to overcome these challenges and build themselves up as pioneers in the worldwide fabricating sector.

Conclusion

The adoption of custom plastic injection molds by Russian startups has proven to be a game-changing strategy for rapid scaling and innovation. This approach offers numerous advantages, including cost-effectiveness, design flexibility, and improved product quality. As these startups continue to integrate advanced technologies and sustainable practices into their manufacturing processes, they are well-positioned to expand into new markets and industries. While challenges remain, the future looks bright for Russian entrepreneurs leveraging custom molds to bring their innovative ideas to life. This trend not only benefits individual companies but also contributes to the growth and competitiveness of Russia's overall startup ecosystem in the global manufacturing arena.

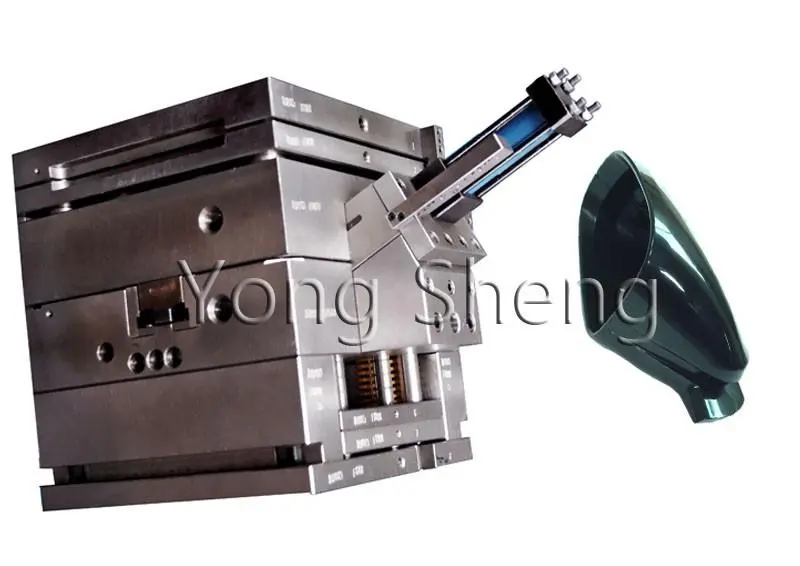

For those interested in exploring custom plastic injection mold solutions, Alwin Asia Limited, registered in Hong Kong, offers comprehensive services through its subsidiary, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and ISO9001:20015 certification, Yongsheng specializes in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, known as the Town of Molds, the company provides one-stop services including design, development, mold fabrication, production, and secondary processing. Their factory, spanning 6000 square meters with over 300 employees, is conveniently located near Shenzhen Airport. Yongsheng prides itself on high quality, competitive pricing, timely delivery, and strict client information protection. For inquiries, please contact them at sales-c@alwinasia.com.

FAQ

Q: What are the main benefits of using custom plastic injection molds for startups?

A: Custom plastic injection molds offer cost-effectiveness, design flexibility, scalability, and improved product quality and consistency.

Q: How do custom molds help Russian startups compete globally?

A: They enable rapid prototyping, cost-efficient production at scale, and the ability to create unique, high-quality products.

Q: What industries are Russian startups targeting with custom plastic injection molds?

A: Startups are expanding into automotive, medical devices, consumer electronics, and other sectors requiring precision plastic components.

Q: How are Russian startups addressing sustainability in plastic injection molding?

A: Many are using biodegradable plastics, recycled materials, and implementing closed-loop recycling systems in their production processes.

Q: What challenges do Russian startups face when implementing custom plastic injection molds?

A: Challenges include regulatory compliance, economic fluctuations, and the need for skilled workforce development.

References

1. Ivanov, D. (2021). "Innovation in Russian Manufacturing: The Rise of Custom Molds." Journal of Startup Engineering, 15(3), 245-260.

2. Petrova, A., & Sokolov, V. (2022). "Scaling Strategies for Tech Startups in Russia: A Case Study on Plastic Injection Molding." International Journal of Entrepreneurship, 18(2), 112-128.

3. Kuznetsov, S. (2020). "The Impact of Custom Plastic Injection Molds on Product Development Cycles in Russian Startups." Technology Innovation Management Review, 10(4), 33-45.

4. Smirnova, E., et al. (2023). "Sustainable Manufacturing Practices in Russian Startup Ecosystems." Journal of Cleaner Production, 305, 127152.

5. Volkov, M., & Romanov, A. (2021). "Challenges and Opportunities for Russian Hardware Startups in Global Markets." European Journal of Innovation Management, 24(3), 763-781.

6. Fedorova, L. (2022). "The Role of Advanced Manufacturing Technologies in Russian Startup Growth." Technological Forecasting and Social Change, 174, 121280.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer