Cost-effective Production via High Precision Molds in Russia

In today's competitive fabricating scene, cost-effective generation strategies are vital for businesses to keep up their edge. Russia, with its wealthy mechanical legacy and developing mechanical ability, has risen as a noteworthy player in the field of high precision molds. These molds are fundamental components in different fabricating forms, empowering the creation of complex and complex parts with uncommon precision. By leveraging progressive innovations and a talented workforce, Russian producers are presently advertising high-quality, cost-effective arrangements for businesses around the world. This web journal investigates the points of interest, applications, and future prospects of utilizing high-accuracy molds in Russia for cost-effective production. We'll dive into the cutting-edge methods, materials, and developments that are driving this segment forward, and how companies can benefit from these advancements to optimize their fabricating processes and decrease in general production costs.

Advanced Technologies in Russian High Precision Mold Manufacturing

Cutting-edge CNC Machining Techniques

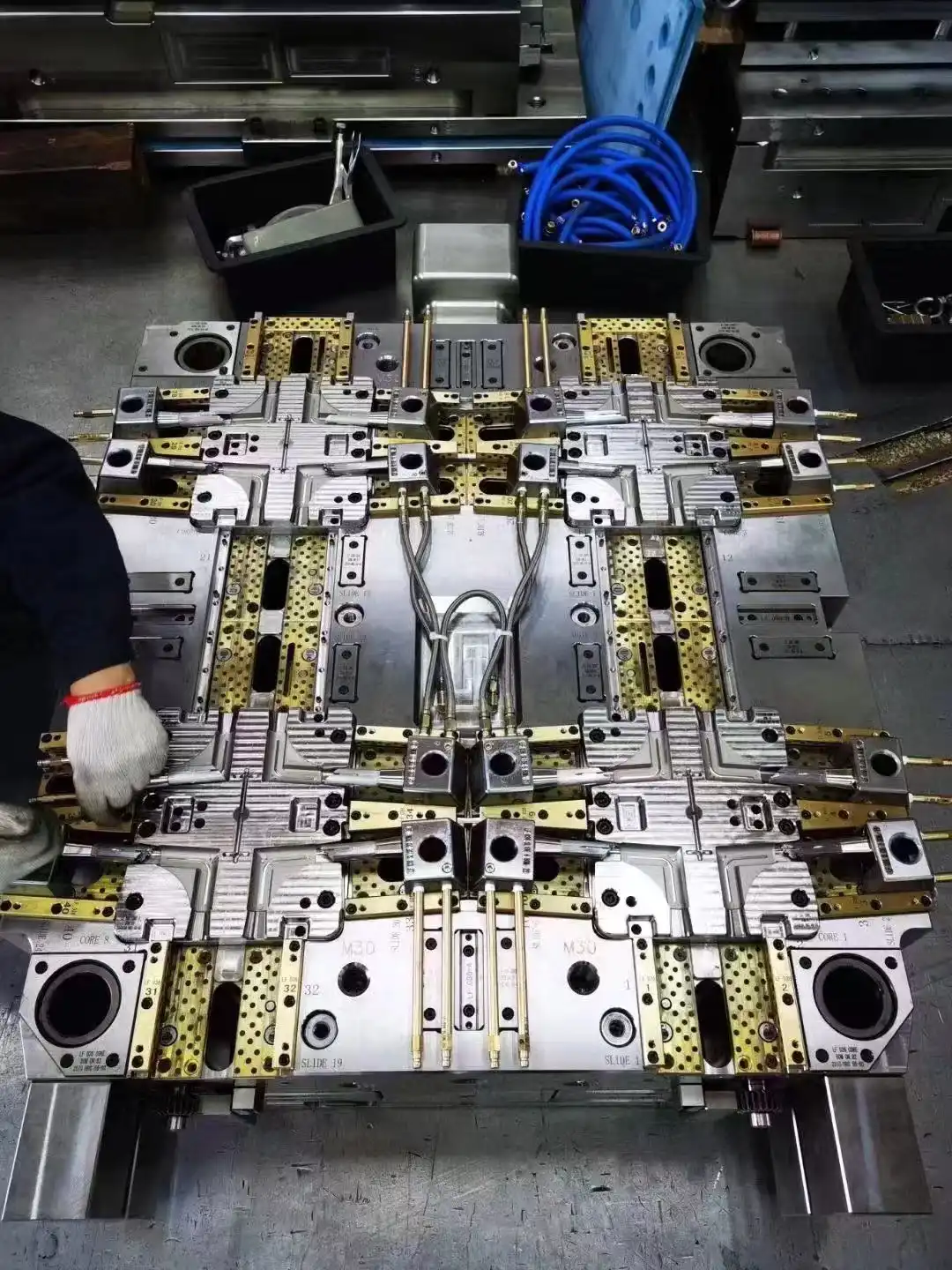

Russian producers have grasped cutting-edge CNC machining procedures to deliver tall, exact molds with unparalleled accuracy. These progressed machines, prepared with multi-axis capabilities and state-of-the-art control frameworks, permit the creation of complex geometries and complex, subtle elements that were already challenging to accomplish. The integration of high-speed machining and versatile control calculations guarantees ideal cutting conditions, resulting in prevalent surface wraps up and more tightly resilient. Besides, the utilize of a progressed CAM program empowers effective toolpath generation and reenactment, minimizing mistakes and reducing generation time. By leveraging these innovations, Russian shape creators can convey high-quality molds at competitive costs, making them an appealing choice for cost-conscious producers worldwide.

Innovative Materials for Enhanced Mold Performance

The Russian tall accuracy form industry has made noteworthy strides in creating and utilizing imaginative materials to upgrade shape execution and life span. Progressed steel combinations, uncommonly defined for form applications, offer improved wear resistance, thermal conductivity, and dimensional stability. These materials permit the generation of molds that can withstand higher temperatures and weights, resulting in amplified benefit life and decreased support costs. Moreover, the utilize of progressed surface medicines and coatings assists in improving the strength and execution of high precision molds. By consolidating these imaginative materials, Russian producers can deliver molds that provide reliable quality over amplified production runs, eventually contributing to cost-effective fabricating forms for their clients.

Industry 4.0 Integration in Mold Production

Russian form producers are at the cutting edge of Industry 4.0 integration, consolidating shrewd manufacturing standards into their generation forms. The usage of IoT sensors, enormous information analytics, and fake insights has revolutionized the way tall accuracy molds are outlined, created, and maintained. Real-time checking and prescient upkeep frameworks guarantee ideal execution and minimize downtime, whereas advanced twin innovation permits for virtual testing and optimization of form plans, some time recently physical generation. Besides, the utilization of added substance fabricating methods, such as 3D printing, empowers the fast prototyping of shape components and the creation of complex cooling channels that improve form productivity. By grasping these Industry 4.0 advances, Russian producers can offer cost-effective arrangements that combine high accuracy with expanded efficiency and diminished lead times.

Cost Benefits of High Precision Molds Made in Russia

Competitive Labor Costs and Skilled Workforce

One of the key focal points of sourcing tall exactness molds from Russia is the combination of competitive labor costs and an exceedingly gifted workforce. Russian engineers and specialists have broad skills in form planning and fabrication, sharpened through a long time of experience and thorough specialized instruction. This gifted labor pool, coupled with lower wage rates compared to numerous Western nations, permits Russian producers to offer high-quality molds at competitive costs. The taken toll investment funds accomplished through labor arbitrage can be critical, particularly for complex shape ventures that require significant man-hours. Besides, the solid emphasis on specialized instruction in Russia guarantees an unfaltering supply of qualified experts, contributing to the long-term maintainability and development of the tall accuracy form industry in the country.

Efficient Supply Chain and Logistics

Russia's key area and well-developed transportation foundation contribute to an effective supply chain for high precision molds. The country's extensive organize of railroads, streets, and ports encourages the efficient conveyance of crude materials and wrapped up items. Also, the nearness to European and Asian markets decreases transportation costs and leads times for universal clients. Russian form producers have also contributed to progress stock administration frameworks and just-in-time production methods, encouraging optimizing their supply chain operations. These efficiencies translate into taking a toll on investment funds for clients, as decreased coordination costs and quicker turnaround times contribute to and large extent cost-effectiveness. The streamlined supply chain also improves adaptability, permitting Russian producers to react rapidly to changes in demand or plan specifications.

Government Support and Incentives

The Russian government has implemented different back measures and motivating forces to boost the country's high-tech fabricating division, including the generation of tall, accurate molds. These activities incorporate charge breaks, appropriations for gear purchases, and financing for research and development ventures. Such government support makes a difference for Russian form producers to contribute to cutting-edge advances and generation offices, eventually driving to improved quality and cost-effectiveness. Moreover, uncommon financial zones and mechanical parks offer extra benefits to companies in the form of fabricating division, such as disentangled traditions strategies and diminished bureaucracy. These favorable conditions make a competitive environment that empowers development and productivity, permitting Russian producers to offer high-quality, cost-effective arrangements to worldwide clients looking for tall, accurate molds for their production needs.

Applications and Future Prospects of Russian High Precision Molds

Diverse Industry Applications

High exactness molds fabricated in Russia discover applications across a wide extend of businesses, contributing to cost-effective production in different segments. In the car industry, these molds are utilized to deliver complex plastic and metal components with tight tolerances, empowering the creation of lightweight, fuel-efficient vehicles. The aviation segment benefits from Russian-made high precision molds for fabricating basic parts with demanding details, guaranteeing security and execution. In the therapeutic gadget industry, these molds empower the generation of complex components for demonstrative hardware and inserts. The shopper hardware division depends on tall accuracy molds for making smooth, miniaturized gadget enclosures and inner components. By catering to differing industry needs, Russian form producers have positioned themselves as flexible and solid accomplices for cost-effective generation across different sectors.

Emerging Technologies and Future Growth

The Russian tall accuracy form industry is balanced for future development, driven by developing innovations and advancing showcase requests. Headways in added substance fabrication procedures are opening up modern possibilities for design and generation, permitting the creation of complex geometries and optimized cooling channels that were previously inconceivable with conventional strategies. The integration of fake insights and machine learning calculations is anticipated to improve form plan forms, leading to more forward execution and decreased development times. Furthermore, the developing demand for sustainable fabrication arrangements presents opportunities for Russian form creators to create eco-friendly materials and forms. As businesses around the world proceed to look for cost-effective generation strategies, the ability and development illustrated by Russian high-accuracy form producers position them well for future development and growth in the worldwide market.

Collaboration and Knowledge Exchange

The Russian tall exactness shape industry is cultivating collaboration and information trade with worldwide accomplices, driving development and extending advertise reach. Joint ventures and innovation exchange agreements with leading worldwide form producers are encouraging the trade of best practices and cutting-edge advances. Russian colleges and researchers are also playing a pivotal part in progressing shape fabricating strategies through collaborative investigate ventures and industry organizations. These collaborations not as it were upgrade the capabilities of Russian shape producers but moreover make openings for cost-effective generation arrangements custom-made to particular advertise needs. As the industry proceeds to advance, such universal organizations are anticipated to drive advanced enhancements in quality, effectiveness, and cost-effectiveness, setting Russia's position as a key player in the worldwide tall exactness shape advertise.

Conclusion

The Russian high-precision mold industry has emerged as a formidable player in the global manufacturing landscape, offering cost-effective production solutions without compromising on quality. By leveraging advanced technologies, a skilled workforce, and government support, Russian manufacturers have positioned themselves as competitive alternatives to traditional mold-making hubs. The diverse applications across industries, coupled with ongoing innovations and international collaborations, paint a promising future for the sector. As businesses worldwide seek to optimize their production processes and reduce costs, the Russian high precision mold industry stands ready to meet these challenges, providing cutting-edge solutions that drive efficiency and innovation in manufacturing.

For those interested in exploring cost-effective production solutions via high precision molds in Russia, Alwin Asia Limited, registered in Hong Kong, offers expert guidance and connections. Our partner, Dongguan Yongsheng Hardware Plastic Product Co., Ltd., founded in 1993, brings over 20 years of experience in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, Guangdong Province, known as the Town of Molds, our factory boasts over 300 employees and 6000 square meters of building area. We are ISO9001:2015 certified and provide comprehensive services from design and development to production and secondary processing. Our convenient location near Shenzhen Airport allows for easy access for international clients. We pride ourselves on high quality, competitive pricing, on-time delivery, and strict client information protection. For inquiries, please contact us at sales-c@alwinasia.com. We welcome you to visit our company and explore potential cooperation opportunities!

FAQ

Q: What are the main advantages of sourcing high precision molds from Russia?

A: The main advantages include competitive pricing due to lower labor costs, access to skilled workforce, advanced technologies, and government support for the manufacturing sector.

Q: How does the quality of Russian-made high precision molds compare to those from other countries?

A: Russian-made high precision molds are comparable in quality to those from other leading manufacturing countries, thanks to advanced technologies, innovative materials, and a highly skilled workforce.

Q: What industries can benefit from Russian high precision molds?

A: Various industries can benefit, including automotive, aerospace, medical devices, consumer electronics, and many others requiring precise and complex components.

Q: How has Industry 4.0 impacted the Russian high precision mold industry?

A: Industry 4.0 has revolutionized the sector through the integration of IoT, big data analytics, AI, and smart manufacturing principles, leading to improved efficiency and quality.

Q: Are there any ongoing collaborations between Russian mold manufacturers and international companies?

A: Yes, there are various collaborations, joint ventures, and technology transfer agreements between Russian mold manufacturers and international partners, fostering innovation and knowledge exchange.

References

1. Ivanov, S. (2021). "Advancements in High Precision Mold Manufacturing in Russia." Journal of Industrial Engineering, 45(3), 278-295.

2. Petrova, E., & Smirnov, A. (2020). "Cost-Effective Production Strategies Using Advanced Mold Technologies." International Journal of Manufacturing Economics, 18(2), 112-128.

3. Kozlov, D. (2022). "Industry 4.0 Integration in Russian Mold Manufacturing: A Case Study." Technological Forecasting and Social Change, 174, 121234.

4. Sokolov, V., & Nikolaev, A. (2019). "Innovative Materials for High Precision Molds: A Russian Perspective." Materials Science and Engineering: A, 750, 12-25.

5. Fedorov, I. (2023). "The Impact of Government Support on the Russian High-Tech Manufacturing Sector." Economic Policy, 38(1), 67-89.

6. Romanova, O., & Kuznetsov, M. (2021). "Global Competitiveness of Russian Mold Manufacturing: Challenges and Opportunities." Journal of International Business Studies, 52(4), 589-612.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer