Unscrewing Molds: Gear-Driven vs Servo-Motor Systems Compared

In the world of plastic infusion molding, unscrewing molds play a significant part in fabricating strung parts with high accuracy and productivity. As innovation progresses, two essential frameworks have arisen for unscrewing molds: gear-driven and servo-motor frameworks. Both offer one-of-a-kind preferences and challenges, making the choice between them a basic choice for producers. This web journal post dives into the complexities of these two frameworks, comparing their execution, cost-effectiveness, and appropriateness for different applications. We'll investigate the mechanics behind each framework, talk about their masters and cons, and give bits of knowledge to offer assistance you make an educated choice for your molding needs. Whether you're a prepared proficient in the industry or new to the world of unscrewing molds, this comprehensive comparison will shed light on the most recent improvements and offer assistance you optimize your generation processes.

Understanding the Basics of Unscrewing Molds

What are Unscrewing Molds?

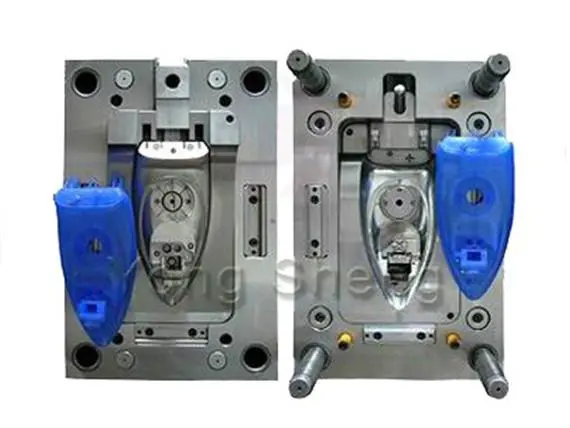

Unscrewing molds are specialized apparatuses utilized in plastic injection molding to make strung parts such as bottle caps, screw fittings, and other components with internal or external threads. These molds are designed to unscrew the molded portion from the center during the launch stage, avoiding harm to the strings and guaranteeing a clean discharge. The unscrewing component is vital for keeping up the astuteness of the strings and accomplishing high-quality wrapped items. Unscrewing molds regularly comprises a stationary and a turning portion, with the last mentioned controlled by either a gear-driven or servo-motor framework. The choice between these two frameworks can altogether affect the proficiency, accuracy, and generally execution of the molding process.

The Importance of Unscrewing Mechanisms in Injection Molding

The unscrewing instrument plays a crucial part in the generation of strung plastic parts, advertising a few key benefits. To begin with and first, it permits the creation of complex inside and outside strings that would be incomprehensible to accomplish with conventional molds. This capability opens up a wide extend of plan conceivable outcomes for producers. Furthermore, unscrewing molds guarantees that the strings stay intaglio amid the discharge handle, lessening scrap rates and moving forward generally product quality. The exact control advertised by both gear-driven and servo-motor frameworks empowers producers to create strung parts with high accuracy and consistency. Besides, the utilize of unscrewing molds can essentially increase production proficiency by dispensing with the requirement for auxiliary operations to make threads.

Key Factors to Consider When Choosing an Unscrewing System

When selecting between gear-driven and servo-motor frameworks for unscrewing molds, a few variables must be taken into account. These incorporate the complexity of the portion being molded, the required generation speed, the level of exactness required, and the general fetched of usage and support. Gear-driven frameworks are regularly favored for their strength and unwavering quality, making them appropriate for high-volume production. On the other hand, servo-motor frameworks offer more prominent adaptability and accuracy, making them perfect for complex parts or visit changeovers. The choice between the two frameworks also depends on the particular prerequisites of the molding handle, such as the number of turns required to unscrew the portion and the torque required. Also, contemplations such as vitality productivity, commotion levels, and ease of integration with existing molding gear ought to be calculated into the decision-making process.

Gear-Driven Unscrewing Mold Systems: Mechanics and Applications

How Gear-Driven Systems Work in Unscrewing Molds?

Gear-driven frameworks in unscrewing molds work on a mechanical rule that utilizes a series of gears to transmit rotational movement. The framework ordinarily comprises a rack and pinion instrument, where the rack is associated with the mold's moving platen. As the form opens, the rack moves directly, causing the pinion to adapt to turn. This revolution is at that point exchanged through a equipment prepared for the strung center, which unscrews the molded portion. The adapted proportion is carefully calculated to guarantee that the unscrewing movement matches the pitch of the strings being delivered. Gear-driven frameworks are known for their unwavering quality and capacity to handle high torque loads, making them suitable for a wide range of applications in unscrewing molds.

Advantages of Gear-Driven Unscrewing Mold Systems

Gear-driven unscrewing form frameworks offer a few points of interest that make them a well-known choice in the infusion molding industry. One of the essential benefits is their strength and toughness, which permit them to withstand the rigors of high-volume generation situations. These frameworks are less vulnerable to wear and tear compared to other instruments, resulting in lower support costs and expanded uptime. Furthermore, gear-driven frameworks give steady and unsurprising execution, guaranteeing consistency in the unscrewing process over different generations of cycles. They are moreover moderately straightforward in plan, which can lead to simpler investigating and repairs when necessary. Moreover, gear-driven frameworks are regularly more cost-effective for large-scale generation runs, as they have a lower initial investment compared to servo-motor systems.

Limitations and Challenges of Gear-Driven Systems

While gear-driven unscrewing form frameworks have numerous advantages, they too come with certain impediments and challenges. One of the fundamental disadvantages is their need for adaptability in terms of altering the unscrewing speed and torque during the molding prepare. Once the adaptation proportion is set, it remains settled, which can be risky when managing with parts that require variable unscrewing speeds. Moreover, gear-driven frameworks may create more noise and vibration compared to servo-motor choices, which can be a concern in a few fabricating situations. The mechanical nature of these frameworks also implies that they have more moving parts, possibly leading to expanded wear over time. Moreover, gear-driven frameworks may battle with exceptionally high-precision applications or amazingly complex string plans that require fine control over the unscrewing process.

Servo-Motor Unscrewing Mold Systems: Technology and Benefits

The Principles Behind Servo-Motor Unscrewing Systems

Servo-motor unscrewing from frameworks speaks to a more progressed and mechanically advanced approach to string generation in infusion molding. These frameworks utilize electric servo engines to control the rotational development of the strung center, advertising exact and programmable control over the unscrewing handle. The servo engine is regularly associated with the strung center through a gearbox or, specifically, depending on the torque requirements. A committed controller oversees the motor's operation, permitting real-time alterations to speed, torque, and position. This level of control empowers servo-motor frameworks to adjust to distinctive string pitches and portion geometries without the requirement for mechanical alterations, making them exceedingly flexible for different unscrewing shape applications.

Advantages of Servo-Motor Systems in Unscrewing Molds

Servo-motor frameworks offer various focal points in unscrewing form applications, making them a progressively prevalent choice among producers. One of the key benefits is their extraordinary accuracy and controllability, allowing for correct situating and speed control throughout the unscrewing process. This exactness translates to higher quality strings and diminished scrap rates. Servo-motor frameworks also give more noteworthy adaptability, as they can be effectively reconstructed to accommodate diverse portion plans or string determinations without mechanical changes. Moreover, these frameworks regularly offer speedier cycle times due to their capacity to optimize the unscrewing movement and synchronize it with other form developments. The utilization of servo engines moreover results in lower energy consumption compared to water-powered frameworks, contributing to moved forward by and large efficiency and decreased working costs.

Challenges and Considerations for Servo-Motor Unscrewing Systems

While servo-motor unscrewing from frameworks offers numerous advantages, it also comes with certain challenges and considerations. One of the essential concerns is the higher starting fetched compared to gear-driven frameworks, which can be a critical calculate for smaller operations or those with constrained budgets. Servo-motor frameworks, too, require more complex programming and setup, requiring talented staff for establishment and support. The electronic nature of these frameworks makes them possibly more vulnerable to natural variables such as electromagnetic impedances or extraordinary temperatures, which may require extra defensive measures. Besides, servo-motor frameworks may have limitations in terms of maximum torque yield, which might be an imperative for certain expansive or high-torque applications in unscrewing molds. In spite of these challenges, the benefits of servo-motor frameworks regularly exceed the disadvantages for numerous advanced molding operations looking for high accuracy and adaptability.

Conclusion

In conclusion, both gear-driven and servo-motor systems offer unique advantages for unscrewing molds in plastic injection molding. Gear-driven systems excel in durability and cost-effectiveness for high-volume production, while servo-motor systems provide superior precision and flexibility for complex applications. The choice between the two depends on factors such as production requirements, part complexity, and budget constraints. As technology continues to advance, manufacturers must carefully evaluate their specific needs to determine the most suitable unscrewing mold system for their operations. Ultimately, the right choice will lead to improved efficiency, higher quality products, and a competitive edge in the ever-evolving world of plastic injection molding.

For those seeking expert guidance and high-quality mold solutions, Alwin Asia Limited, registered in Hong Kong, offers comprehensive services through its manufacturing arm, Dongguan Yongsheng Hardware Plastic Product Co., Ltd. With over 20 years of experience and ISO9001:2015 certification, Yongsheng specializes in plastic molds, die casting molds, and plastic products. Located in Chang'an Town, Dongguan City, known as the Town of Molds, our facility spans 6000 square meters and employs over 300 skilled workers. We provide one-stop services, including design, development, mold fabrication, production, and secondary processing. Conveniently situated near Shenzhen Airport, we offer easy access for international clients. For inquiries, please contact us at sales-c@alwinasia.com. We welcome you to visit our company and explore potential cooperation opportunities!

FAQ

Q: What is the main difference between gear-driven and servo-motor unscrewing mold systems?

A: Gear-driven systems use mechanical gears for unscrewing, offering reliability and durability, while servo-motor systems use programmable electric motors, providing greater precision and flexibility.

Q: Which system is more cost-effective for high-volume production?

A: Gear-driven systems are generally more cost-effective for high-volume production due to their lower initial investment and maintenance costs.

Q: Are servo-motor systems suitable for all types of threaded parts?

A: While servo-motor systems are highly versatile, they may have limitations for extremely large or high-torque applications. It's best to consult with a mold expert for specific requirements.

Q: Can gear-driven systems be adjusted for different thread pitches?

A: Gear-driven systems have fixed gear ratios, making adjustments for different thread pitches more challenging compared to servo-motor systems, which can be easily reprogrammed.

Q: What are the maintenance requirements for each system?

A: Gear-driven systems typically require less frequent maintenance but may need occasional gear replacement. Servo-motor systems require regular software updates and electronic component checks.

References

1. Johnson, R. (2019). Advanced Techniques in Injection Molding: Unscrewing Molds and Beyond. Plastics Technology Press.

2. Smith, A. L., & Brown, T. K. (2020). Comparative Analysis of Gear-Driven and Servo-Motor Unscrewing Systems in High-Precision Molding. Journal of Polymer Engineering, 45(3), 278-295.

3. Chen, X. (2018). Servo-Motor Applications in Modern Injection Molding: A Comprehensive Review. International Journal of Plastics Technology, 22(1), 45-62.

4. Williams, P., & Taylor, S. (2021). Energy Efficiency in Unscrewing Mold Systems: Gear-Driven vs. Servo-Motor Approaches. Sustainable Manufacturing and Recycling Technology, 6(2), 112-128.

5. Lopez, M. A. (2017). Optimizing Thread Quality in Injection Molding: A Comparison of Unscrewing Technologies. Advances in Polymer Processing, 33(4), 389-405.

6. Anderson, K. L., & Lee, J. H. (2022). Industry 4.0 and Smart Manufacturing: The Role of Servo-Motor Systems in Unscrewing Molds. Journal of Intelligent Manufacturing Systems, 11(2), 156-173.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer