When foreign businesses think about making plastic products in China, they need to know how the OEM/ODM landscape works. The plastics industry in China has changed a lot in the last 20 years. Now, they offer advanced polymer materials knowledge, advanced injection molding skills, and full supply chain solutions. Companies can expect reasonable prices, the ability to change the amount of work they do, and access to state-of-the-art plastic molding tools. The key is to work with well-known manufacturers who have a track record of making plastic parts, setting up quality control methods, and protecting intellectual property. These days, modern factories in China use reusable and biodegradable plastics in their production. This helps them meet global standards for sustainability while keeping costs low.

Understanding OEM/ODM Manufacturing and Market Positioning

Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) are two different ways to make plastic products. OEM manufacturing is the process of making plastic parts based on the designs and specs you already have. Your company owns the design and uses China's production know-how for processes like plastic extrusion and injection molding.

More can be done when people work together on ODM. Manufacturers in China help with design by coming up with new ideas based on their knowledge of thermoplastics, plastic resins, and how to make plastic items. This method works really well when entering new markets or coming up with ideas for plastic boxes that can be made in the country where they are used.

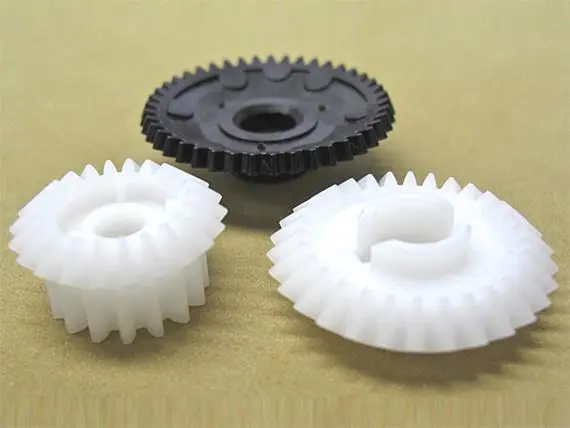

Deep customization matters because today's competitive landscape demands differentiated plastic components. Whether developing plastic containers for consumer goods, automotive plastic parts, or electronics housings, customization enables brand positioning and functional optimization. Chinese manufacturers excel at adapting polymer materials and plastic additives to meet specific performance requirements.

Yongsheng's Comprehensive OEM/ODM Manufacturing Strengths

Yongsheng is a trusted partner in China's plastics business because we have been making things for 30 years. We've seen how the Chinese industry has changed from simple production to advanced engineering skills since 1993. With over 300 skilled workers spread out over 6,000 square meters, our Dongguan facility has the level of expertise that foreign companies are looking for.

We care about quality control at every step of the plastic-making process because we are ISO 9001:2015 qualified. As part of our quality control, we carefully check all of the finished plastic parts and the plastic resins that are used as raw materials. We also keep an eye on the injection molding process. Each batch of goods is made with the same amount of care using this method.

Research and development capabilities enable us to work with advanced polymer materials, including recyclable plastics and specialized thermoplastics. Our engineering team collaborates with international partners to optimize plastic products design for manufacturability while maintaining functional requirements.

Supply chain integration streamlines procurement of plastic additives, packaging materials, and secondary components. Our location in Dongguan's "Town of Molds" provides access to specialized suppliers and reduces lead times for complex plastic manufacturing projects. Scalability accommodates everything from prototype development to mass production. Our plastic molding machines handle varying production volumes while maintaining cost-effectiveness across different order quantities.

Extensive Customization Options for Plastic Components

Customizing the physical design includes setting the right dimensions, figuring out the best wall thickness, and specifying the surface finish. Our engineering team works with different thermoplastics to get the mechanical features we need, while also taking things like how well the plastic can be recycled and how it should be thrown away into account.

Functional feature integration meets certain needs for speed. We choose the right polymer materials and plastic additives to meet the needs of our customers, whether they want plastic containers with better barrier qualities or parts for cars that need to be able to handle high temperatures. Adding computer parts, sensors, or smart features to plastic housings is an example of technology integration. Because we have a lot of experience making electronics, we can easily add technical parts to plastic parts.

Branding customization extends beyond basic logo placement. We develop comprehensive plastic packaging solutions that reflect brand identity through color matching, texture development, and distinctive design elements that differentiate products in competitive markets. Compliance management ensures plastic components meet international standards, including FDA regulations for food contact, automotive industry specifications, and electronics safety requirements. Our quality systems track regulatory compliance throughout the manufacturing process.

Packaging solutions encompass both product packaging and shipping protection. We develop custom plastic packaging that protects components during transportation while supporting brand presentation at the point of sale.

The ODM Advantage in Collaborative Product Development

ODM partnerships let companies work together to come up with new ways to make plastic products that use China's production know-how. Our design team has decades of experience making plastic goods, so they know how choosing the right material affects how well the product works and how quickly it can be made.

Market insight from our international customer base informs design decisions. We understand global trends in plastic packaging, sustainability requirements for recyclable plastics, and emerging applications for biodegradable plastics. This knowledge helps optimize products for multiple markets simultaneously. Cost optimization through design modifications can significantly impact project economics. Our engineers identify opportunities to reduce material usage, simplify plastic molding processes, and eliminate unnecessary features without compromising functionality.

When you combine your knowledge of the market with our knowledge of manufacturing, innovation speeds up. We keep up with changes in polymer materials, plastic molding methods, and environmentally friendly ways to make things that make our products more competitive. Manufacturing problems are less likely to happen when risks are reduced through joint development. Being involved in the planning process helps find problems early on, which makes sure that the change from the prototype to full production goes smoothly.

Our Streamlined Customization Process

Initial consultation starts with learning about your plastic product needs, how you want to place your business in the market, and how much you expect to buy. We look over current designs or talk about ideas for making a new product, setting clear goals for the project and expectations for when it will be finished. Design development includes making thorough plans for plastic parts, picking the right thermoplastics or other polymer materials, and designing to work best for injection molding. During this phase, our team keeps you up to date on progress and uses your comments to improve things.

Prototyping validates design concepts using production-grade plastic resins and manufacturing processes. This stage allows testing of mechanical properties, dimensional accuracy, and functional performance before committing to full-scale tooling investment. Tooling fabrication leverages our in-house mold-making capabilities. We manufacture precision tools for injection molding, ensuring optimal part quality and production efficiency. Our location in the "Town of Molds" provides access to specialized tooling expertise.

Before production starts, there are tests to make sure that quality methods and production processes work. We slowly increase output until it reaches full capacity while keeping an eye on quality metrics and delivery performance. Ongoing support encompasses inventory management, quality monitoring, and continuous improvement initiatives. Our partnership extends beyond initial production to support long-term business growth.

Comprehensive Benefits for International Partners

Cost benefits go beyond just lower labor costs. They also include buying materials in bulk at lower prices, making plastic products more efficiently, and improving the logistics of the supply chain. Because we have long-term relationships with suppliers of polymer materials, we can offer reasonable prices on high-quality plastic resins.

Systematic methods for quality assurance make sure that the specifications of plastic products are always the same across production runs. Our ISO certification shows that we are dedicated to quality management, which is something that supply chains for foreign companies need.

Delivery reliability stems from proven logistics capabilities and strong relationships with shipping partners. Our proximity to major ports facilitates efficient international shipping, while our inventory management systems support just-in-time delivery requirements. Concerns about design privacy and patent security are dealt with by intellectual property protection. During the whole manufacturing process, we follow strict rules about privacy and put in place security measures to keep private information safe.

Technical support includes ongoing engineering assistance for product modifications, material substitutions, or manufacturing optimization. Our team remains available to address technical questions and support continuous improvement initiatives. Sustainability benefits include access to recyclable plastics, biodegradable plastic options, and manufacturing processes that minimize plastic waste. We help international companies meet sustainability goals while maintaining performance standards.

Conclusion

International companies looking for reliable OEM/ODM partnerships can find a lot of possibilities in China's plastic manufacturing scene. For success, you need to choose manufacturers with a lot of knowledge, quality systems that have been shown to work, a wide range of capabilities, and strong IP protection protocols. Because Yongsheng has been making plastic products for 30 years, is ISO certified, and is located in Dongguan's manufacturing hub, we can give foreign projects the customization, quality, and dependability they need. In today's competitive market, your plastic manufacturing needs will get the knowledge and attention they deserve thanks to our dedication to environmentally friendly practices, technical innovation, and customer partnership.

FAQ

Q: What quality certifications does Yongsheng maintain for plastic manufacturing?

A: Yongsheng holds ISO 9001:2015 certification and maintains comprehensive quality management systems covering all aspects of plastic product manufacturing. Our quality protocols encompass raw material inspection, in-process monitoring, and final product testing to ensure consistent quality across all production runs.

Q: How does Yongsheng protect intellectual property during OEM/ODM projects?

A: We implement strict confidentiality protocols, including secure data management, limited access controls, and comprehensive non-disclosure agreements. Our security measures protect proprietary designs, technical specifications, and business information throughout the manufacturing relationship.

Q: What sustainable plastic materials can Yongsheng work with?

A: Our capabilities include recyclable plastics, biodegradable plastic materials, and bio-based polymer alternatives. We stay current with sustainable material innovations and can recommend environmentally responsible options that meet performance requirements while supporting your sustainability goals.

Partner with Yongsheng for Your Custom Plastic Product Manufacturing Needs

Through our full OEM/ODM manufacturing skills, Yongsheng is ready to make your plastic component needs come true. We are the best company to get plastic products from for foreign projects because we have modern facilities, quality certifications, and 30 years of experience in China's plastic industry. Our team can help you with custom injection molding, choosing the right polymer materials, or the whole process of product development. We'll find solutions that meet your needs while minimizing costs and improving delivery times.

Our location in Dongguan's manufacturing hub provides unparalleled access to supply chain resources, while our 6,000-square-meter facility houses advanced plastic molding machines and experienced engineering personnel. We understand the complexities of international business and maintain the quality systems, IP protection protocols, and communication standards that global companies require from their manufacturing partners.

Take the next step toward realizing your plastic manufacturing goals by connecting with our experienced team. We're prepared to discuss your specific requirements, provide technical recommendations, and develop customized solutions that drive your business success. Contact us at sales@alwinasia.com to begin exploring how Yongsheng can support your next plastic product development project with our proven OEM/ODM expertise.

References

1. China Plastics Processing Industry Association. "Annual Report on China's Plastic Manufacturing Industry Development." 2023.

2. Manufacturing Engineering Society. "Quality Management Systems in Chinese Plastic Manufacturing: Best Practices and Standards." Industrial Engineering Quarterly, 2023.

3. International Trade Commission. "Global Plastic Components Market Analysis: China's Role in OEM/ODM Manufacturing." Trade Review Journal, 2023.

4. Guangdong Provincial Manufacturing Association. "Dongguan Manufacturing Cluster Development: Focus on Plastic and Mold Industries." Regional Development Studies, 2023.

5. Polymer Processing Institute. "Sustainable Plastic Manufacturing Practices in East Asian Production Facilities." Environmental Manufacturing Review, 2023.

6. Supply Chain Management Association. "Risk Management in International Plastic Component Sourcing: China Market Analysis." Global Procurement Quarterly, 2023.