Global Mold Sourcing: Key Supplier Considerations

When purchasing molds from around the world, procurement managers have to make a big choice that affects the quality of the product, the time it takes to make it, and how much it costs overall. Knowing the most important things to think about when choosing an injection mold source will help you make your manufacturing process run more smoothly and protect your investment. The best partner has professional know-how, clear communication, quality standards, and a history of on-time delivery. In the 20 years that Yongsheng has been in business, we've seen that good buying relationships depend on judging a supplier's skills in a number of areas, such as how well they protect intellectual property and how well their tools work. This complete guide talks about the most important things that purchasing professionals should think about when choosing a mold-making partner for custom metal and plastic parts.

Understanding Core Injection Mold Processes and Materials

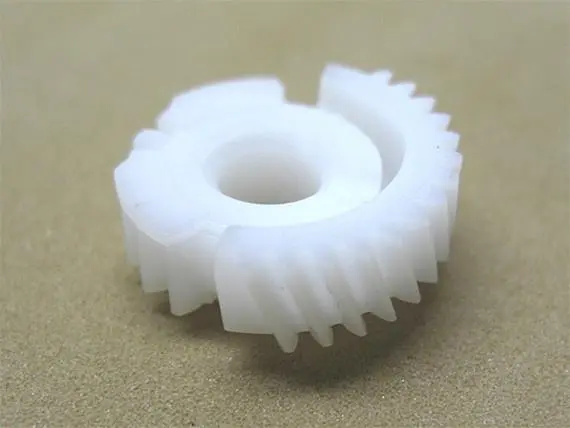

By giving plastics precise shapes and sizes, tools for shaping plastics into goods have made mass production possible. These tools are used a lot in many industries, like gadgets, home products, and cars. The main structure has both moving and set molds, as well as systems for filling, controlling temperature, and ejecting. Being aware of these basic parts helps purchasing teams decide if a provider has the technical background needed for your unique application.

How Injection Molding Technology Works

Before the injection molding process can start, the raw plastic needs to be heated until it melts. Then, this melted substance is pushed under a lot of pressure into a mold hole that was carefully designed. Once the material covers the whole shape of the hole, controlled cooling sets it into the desired shape that was wanted. After being formed, the part is released from the cast and is now ready for further work or final assembly. Because this cycle happens thousands or even millions of times, mold longevity and accuracy are the most important things to look for in a provider. Temperature control systems are very important during this whole process. Suppliers who are good at advanced thermal management can keep cooling rates steady, which cuts down on cycle times and stops common problems like bending or uneven dimensions. When looking at possible partners, you should ask a lot of questions about their temperature control tools and their ability to keep an eye on the process.

Molding Process Categories and Their Applications

Molding can be broken down into six different types: extrusion, blow molding, vacuum forming, injection molding, and high foaming polystyrene molding. Each method is best for different types of materials and industrial needs. Injection molding is still the most flexible choice for complicated shapes and large production runs. Compression molding works well for thermoset materials and bigger items, where the cost of the tools needs to be kept low. Extrusion makes shapes that are continuous, like tubes or sheets, and blow molding makes empty cases. Vacuum making is a cheap way to make bigger parts with easier shapes, and expanded polystyrene molding is used for things like packing and insulation. Suppliers who are knowledgeable in more than one type of shaping show they have more technical skills and can help you choose the best process for your unique component needs.

Mold Materials and Their Impact on Longevity

The two main types of materials used to make molds are steel and aluminum. Injection molds made of hardened steel last a very long time and are perfect for production runs that go over 100,000 rounds. These tools can handle the roughness of glass-filled resins and keep their measurements even during long production runs. Different types of steel, like P20, H13, and S7, have different strength and machinability properties that make them good for different uses. Aluminum tools, on the other hand, can be made faster and cost less at first, making them a good choice for making prototypes and small production runs. If you take good care of modern aluminum alloys like 7075 and QC-7, they can last an amazing amount of time—sometimes 50,000 rounds or more. At our Dongguan plant, we've successfully made models out of both steel and aluminum. This lets us suggest the best material for you based on your expected number and budget.

Critical Criteria for Selecting Injection Mold Suppliers Globally

Selecting the right manufacturing partner requires systematic evaluation across multiple performance dimensions. Quality certifications, production capabilities, and operational flexibility all contribute to successful long-term partnerships.

Quality Certifications and Compliance Standards

If a provider has ISO 9001:2015 approval, you can be sure that they follow written quality control methods. We got this license at Yongsheng to show that we are dedicated to uniform processes and constant growth. But licenses that are specific to a business are often more important than general quality standards. Medical device makers need suppliers to be compliant with ISO 13485, while automotive suppliers should have IATF 16949 certification. Check that suppliers do more than just hang papers on the wall; see if they do regular internal checks and take part in customer quality reviews. Suppliers who are open and honest let customers visit their factories and are happy to share inspection reports, process capability studies, and paperwork for correction actions. After working with clients from around the world for more than twenty years, we know that approval is just the beginning of high greatness, not the end.

Manufacturing Capabilities and Technology Infrastructure

These days, making molds requires high-tech tools and skilled workers. CNC machine centers that work at high speeds can make the complicated shapes needed for multi-cavity tools. Electrical discharge machining (EDM) can make features that are too complicated to be cut with regular tools. Coordinate measuring machines (CMM) check the correctness of dimensions to limits measured in microns. Here are the main technical skills that set modern mold makers apart: Production capacity includes both the number of machines and the skill of the people who run them. Suppliers who work three shifts have a lot of production capacity, and those who keep a wide range of tools can handle a wide range of project challenges. We have a 6,000-square-meter building in Dongguan where over 300 skilled workers use modern machines for casting and cutting. We can work on several projects at once and still meet our quality standards and delivery dates thanks to this scale.

- Multi-cavity tooling expertise: The ability to design and manufacture molds with multiple cavities directly impacts your per-unit production costs. Suppliers experienced in family molds can produce several different components in a single molding cycle, maximizing efficiency for product assemblies with multiple plastic parts.

- Rapid prototyping services: Speed to market often determines competitive advantage. Suppliers offering quick-turn prototype tooling enable faster design validation and market testing. Aluminum prototype molds can be ready within two to three weeks, allowing you to verify form, fit, and function before committing to production tooling.

- Secondary operations integration: Comprehensive suppliers provide finishing services like ultrasonic welding, pad printing, assembly, and packaging. This one-stop capability simplifies your supply chain and reduces coordination overhead across multiple vendors.

These technological capabilities work together to ensure your components meet specifications consistently across production runs. Suppliers who invest continuously in equipment upgrades demonstrate their commitment to remaining competitive in precision manufacturing.

Balancing Lead Time, Cost, and Customization

Every procurement decision involves trade-offs between speed, price, and product customization. Standard catalog tooling ships quickly but rarely matches your exact requirements. Fully customized molds deliver perfect alignment with your specifications but require longer development cycles and higher investment. Realistic lead time expectations vary by mold complexity and supplier workload. Simple two-plate molds might be completed in four to six weeks, while complex multi-cavity tools with automated inserts can require twelve to sixteen weeks. We've found that transparent communication about realistic timelines prevents frustration and allows proper production planning. Rush charges can sometimes accelerate delivery, but understanding normal lead times helps budget planning and avoids unnecessary premium costs.

Comparing Global Injection Mold Supplier Options: China, USA, and Europe

Geographic location influences pricing, lead times, communication dynamics, and supply chain considerations. Each major manufacturing region offers distinct advantages depending on your priorities and project requirements.

Advantages of Sourcing from Chinese Manufacturers

China's manufacturing ecosystem provides unmatched scale and cost competitiveness for tooling production. Guangdong Province alone hosts thousands of injection mold manufacturers, creating intense competition that benefits international buyers through competitive pricing. Our location in Dongguan, known as the "Town of Molds," places us at the center of this manufacturing hub with ready access to specialized materials, components, and skilled labor. The cost advantages extend beyond just labor rates. Chinese suppliers benefit from integrated supply chains where steel suppliers, component manufacturers, and finishing service providers operate in proximity. This clustering effect reduces logistics costs and accelerates production timelines. We can often source specialized mold components within the same district, maintaining quality control while keeping costs competitive. Modern Chinese manufacturers have invested heavily in advanced equipment and quality systems to meet international standards. The outdated perception of compromised quality no longer applies to established manufacturers with proper certifications and experienced management teams. Our ISO 9001:2015 certification and two decades of serving international clients demonstrate this evolution toward world-class capabilities.

North American and European Supplier Characteristics

United States and European mold manufacturers emphasize engineering support and rapid response capabilities. Proximity to your design team facilitates face-to-face meetings during development phases and enables quick iterations when design changes occur. Time zone alignment simplifies communication, and cultural familiarity reduces misunderstandings around specifications and expectations. These suppliers typically charge premium prices that reflect higher labor costs and stricter regulatory environments. However, the investment can be justified for complex applications requiring extensive engineering collaboration or when intellectual property concerns override cost considerations. Domestic suppliers also reduce supply chain risks associated with long ocean transit times and potential customs delays.

Sustainability and Green Manufacturing Practices

Environmental responsibility has evolved from a nice-to-have feature to a fundamental requirement across all manufacturing regions. Leading suppliers now implement energy-efficient molding machines, material recycling programs, and water conservation systems. These practices reduce environmental impact while often lowering operational costs through improved efficiency. European manufacturers often lead in sustainability certifications and renewable energy adoption, driven by strict environmental regulations. Chinese suppliers are rapidly advancing in this area as domestic environmental standards tighten and international customers demand verifiable green practices. When evaluating suppliers, request information about their environmental management systems and specific initiatives around energy consumption and waste reduction.

Avoiding Common Pitfalls in Global Mold Sourcing

Understanding potential challenges allows procurement teams to implement preventive measures rather than reactive solutions. Many sourcing problems are predictable and preventable through proper planning and supplier selection.

Quality Defects and Process Consistency Issues

Common shaping flaws, such as bending, short shots, sink marks, and flash, are usually caused by wrong process settings or mistakes in the design of the tools. When cooling rates are different in different parts of a part, internal forces form that cause the part to bend after it is ejected. Short shots happen when there isn't enough material to fill the hole, leaving parts that aren't finished. Sink marks show up as depressions in thick parts where the material inside shrinks more than the top layers. To avoid these problems, your design team and the mold provider need to work together during the creation phase. Design for manufacturability reviews find places where problems might happen before the steel is cut. Mold flow analysis models how the material will behave during injection, which lets you see what problems might happen and make changes to the design. We do these studies for our clients all the time, which keeps them from having to make expensive changes to the tools after production starts. Setting clear quality acceptance standards before production stops arguments about what parts are good enough. Detailed inspection plans that include measuring methods, sample amounts, and acceptable limits set clear standards that everyone can understand. Keeping in touch during testing and early production runs makes it easy to fix any problems quickly, before they affect delivery dates.

Managing Communication Across Borders and Time Zones

Misunderstandings that can slow down projects can be avoided by having clear paperwork. It is clear what the key measurements are when you have detailed models with geometric dimensioning and tolerancing (GD&T). Instead of private names, material specs should refer to foreign standards like ASTM or ISO. Surface finish needs to be described with numbers (Ra values) instead of vague words like "smooth" or "polished."During the tools creation stage, alignment is kept up to date with regular project reports. During busy projects, weekly status calls keep everyone up to date on important milestones and possible problems. We've found that upfront discussion about delays or technology issues leads to better problem-solving by everyone, rather than shocks at the last minute. When working with people from other countries, language skills are very important. When suppliers have project managers who speak English, expert conversations are easier to understand, and problems are solved faster. At Yongsheng, we have English-speaking employees who act as single points of contact for customers from other countries, making sure that nothing gets lost in translation.

Protecting Your Investment Through Due Diligence

Risk is greatly reduced when suppliers are carefully checked out. Checking references with past customers gives you more information about how well a product or service really works than what the marketing papers say. Ask specific questions about how often deliveries are made on time, how quickly problems are fixed, and how willing they are to deal with problems helpfully. Factory checks show skills that can't be checked from afar. Looking at the state of the tools, the cleanliness standards, and how engaged the employees are can tell you a lot about operating development. International customers can easily visit our plant since it's only 20 minutes from Shenzhen Airport. We encourage potential clients to look around before they decide where to buy from us. Strong guarantee policies protect the money you spend on tools. Under normal working conditions, standard guarantees should cover flaws in the work and premature tool wear. Having clear words about who is responsible for upkeep, how long the cycle should last, and how long the covering lasts stops disagreements. We back up our tools with full guarantees because the molds we make are meant to last a long time.

Yongsheng: Your Trusted Partner for Precision Injection Mold Manufacturing

We at Yongsheng have been making injection molds for the electronics, automobile, consumer goods, and tools industries since 1993, giving us more than twenty years of specialized knowledge. Our wide range of skills covers the whole production process, from helping with the initial design to making the molds, shaping the parts, and finishing them off. This combined method gets rid of the problems that come with coordinating and makes sure that everyone is responsible for the project. As a board member of the Dongguan City Hardware Machinery Mould Industry Association, we keep strong ties with the local industrial community and follow the highest standards of professionalism. Our ISO 9001:2015 certification shows that we are dedicated to clear quality systems and constant growth. We are experts in both plastic injection molds and die-casting molds. We are especially good at multi-cavity equipment that helps you make the most of your production. Our service stands out because we offer affordable prices and strict intellectual property security. We know that your ideas are a big investment and a way to beat the competition. During our partnership, your private information will be kept safe by our secrecy agreements and secure data handling procedures. Many customers from around the world have given us their most private projects because we take intellectual property security just as seriously as quality and on-time delivery. Our 6,000-square-meter building has modern CNC machine centers, EDM equipment, and high-precision checking tools that are run by more than 300 trained workers. This size lets us work on several projects at once and still be able to handle rush orders when the market needs us to. Being in Chang'an Town, Dongguan—known as the "Town of Molds"—makes it easy for us to access specialized sources and skilled workers who help us make molds of the highest quality. We want sourcing managers and product creators to work directly with us and see what makes Yongsheng different. Our engineering team can come up with solutions that are perfect for your needs, whether you need fast development to test a new design or high-volume production tools for well-known goods. Email us at sales@alwinasia.com to talk about your future projects with a seasoned injection mold provider who wants you to succeed. Visitors can take trips of our plant, and we can pick them up from Shenzhen Airport or Luohu, which are only 20 to 50 minutes away.

Conclusion

When looking for injection molds around the world, you need to carefully consider the skills, certifications, contact methods, and culture fit of the suppliers. The right partner has professional know-how, clear processes, and service that is focused on the customer. Procurement teams can make better choices that combine cost, quality, and delivery efficiency when they know about casting methods, choosing materials, and the benefits of different regions. Companies can build relationships that help them reach their manufacturing goals for years to come by screening potential partners carefully and keeping the lines of communication open throughout the relationship. Choosing the right mold provider is an investment that pays off in the form of regular quality, on-time supplies, and working together to solve problems when they come up.

FAQ

Should I choose custom or standard molds for my project?

Custom molds make sense when your component has unique geometry, specific performance requirements, or proprietary features that differentiate your product. The higher initial investment delivers parts optimized for your exact application. Standard or catalog molds work well for common shapes where customization provides minimal value. Projects with budget constraints or tight timelines sometimes benefit from modified standard tooling that adapts existing designs to your needs. Evaluate your volume projections, competitive positioning, and technical requirements to determine which approach delivers the best total value.

What lead times should I expect from different global suppliers?

Lead times vary significantly based on mold complexity and supplier location. Simple prototype molds from Chinese manufacturers typically require four to six weeks, while production tools range from eight to sixteen weeks, depending on cavity count and technical features. North American and European suppliers often quote similar or slightly longer timeframes despite geographic proximity, due to higher labor costs that limit shift coverage. Rush services can sometimes reduce delivery time by 20-30% for premium charges. Always request realistic schedules rather than optimistic promises, and build buffer time into your production planning to accommodate potential delays.

How can I assess a supplier's quality assurance capabilities?

Request documentation of their quality management system, including process flow charts, inspection procedures, and statistical process control methods. ISO certification provides baseline assurance, but industry-specific certifications demonstrate deeper expertise. Ask about their inspection equipment capabilities—CMM machines, optical comparators, and surface finish testers indicate serious quality infrastructure. Reference checks with existing customers reveal real-world performance better than marketing claims. During factory visits, observe housekeeping standards and employee engagement, which correlate strongly with quality culture. Suppliers confident in their capabilities welcome detailed quality discussions and provide transparent access to their processes.

What intellectual property protections should I require?

Comprehensive non-disclosure agreements (NDAs) represent the foundation of IP protection. These contracts should specifically address design files, technical specifications, and proprietary processes. Clarify ownership of tooling and associated intellectual property—some agreements grant you ownership of the physical molds while the supplier retains manufacturing rights, which could limit your flexibility. Discuss data security practices for CAD files and technical documentation. Reputable suppliers implement secure file transfer protocols and restrict access to sensitive information. Consider registering critical designs in the manufacturing country to strengthen legal protections, particularly for products with significant market potential.

How do I balance cost savings with quality requirements?

Cost and quality need not be mutually exclusive when you work with capable suppliers. Focus on the total cost of ownership rather than just tooling price—cheap molds that produce defective parts or fail prematurely cost more than quality tools with higher initial prices. Clearly define your quality requirements using objective specifications rather than subjective standards. Request process capability studies demonstrating the supplier can meet your tolerances consistently. Consider tiered approaches where critical components receive premium tooling while less critical parts use cost-optimized solutions. Long-term partnerships with reliable suppliers often yield better value than constantly chasing the lowest bid across multiple vendors.

Partner with Yongsheng for Reliable Global Mold Sourcing

Choosing the right injection mold supplier sets the foundation for manufacturing success across your product lifecycle. Yongsheng brings proven expertise, modern facilities, and customer-focused service to every project we undertake. Our comprehensive capabilities eliminate the complexity of managing multiple vendors, while our competitive pricing reflects the advantages of China's manufacturing ecosystem without compromising quality or IP protection. We understand the challenges procurement managers face and have structured our operations to address your priorities around cost-effectiveness, on-time delivery, and transparent communication. Reach out to our team at sales@alwinasia.com to discuss how our injection mold manufacturing capabilities can support your upcoming projects. Request a detailed quote or arrange a factory visit to experience our commitment to excellence. Let us demonstrate why leading electronics, automotive, and consumer goods companies trust Yongsheng as their preferred mold manufacturing partner.

References

1. Rosato, D.V. and Rosato, M.G. (2012). Injection Molding Handbook. 3rd Edition. Springer Science & Business Media.

2. Malloy, R.A. (2011). Plastic Part Design for Injection Molding: An Introduction. 2nd Edition. Hanser Publications.

3. Crawford, R.J. and Throne, J.L. (2002). Rotational Molding Technology. William Andrew Publishing.

4. Rees, H. (2002). Mold Engineering. 2nd Edition. Hanser Gardner Publications.

5. Kazmer, D.O. (2007). Injection Mold Design Engineering. Hanser Gardner Publications.

6. Beaumont, J.P. (2004). Runner and Gating Design Handbook: Tools for Successful Injection Molding. Hanser Gardner Publications.

We can provide a one-stop service, including design and development, mold fabrication, production, product processing, etc.

Professional injection mold, die casting mold, plastic products OEM manufacturer